A centrifugal casting machine

A technology of centrifugal casting machine and centrifuge, which is applied in the field of casting, can solve the problems of insufficient density of pipe fittings, achieve the effect of improving molding purity, increasing success rate, and eliminating vibration problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further detailed explanation through specific implementation mode below:

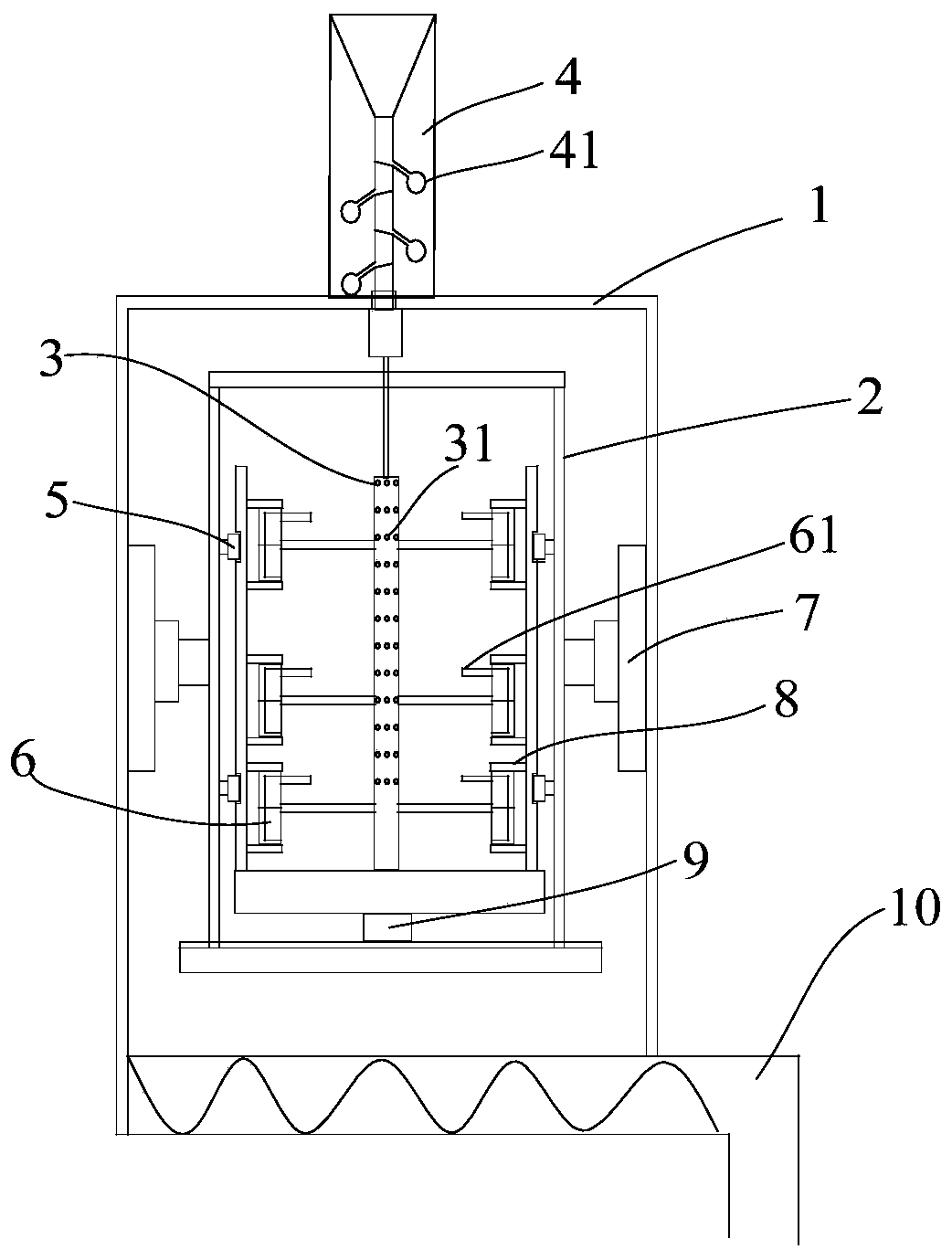

[0015] The reference signs in the accompanying drawings list: shell 1, rotating barrel 2, sprue column 3, warming pipe 31, filter 4, filter residue ball 41, guide wheel 5, ceramic mold 6, ceramic tube 61, telescopic hydraulic cylinder 7 , electromagnetic generator 8, high-speed motor 9, sand-discharging mechanism 10.

[0016] Such as figure 1 The centrifugal casting machine shown includes a casing 1, and a vertically placed centrifuge is arranged inside the casing 1. The centrifuge includes a base, a rotating barrel 2, and a high-speed motor 9 is installed at the center of the bottom of the rotating barrel 2, and the rotation center of the rotating barrel 2 is set There is a mold mounting seat, and the pouring device is fixedly installed on the mold mounting seat. The pouring device includes a sprue column 3 in the center of the rotating barrel 2, and a sprue filter 4 is connected to the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com