Rapid wiring terminating mechanism

A terminal and termination technology, applied in the field of electrical conduction, can solve the problems of unfavorable promotion and application of electrical connectors, achieve the effects of shortening disassembly time, minimizing losses, and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

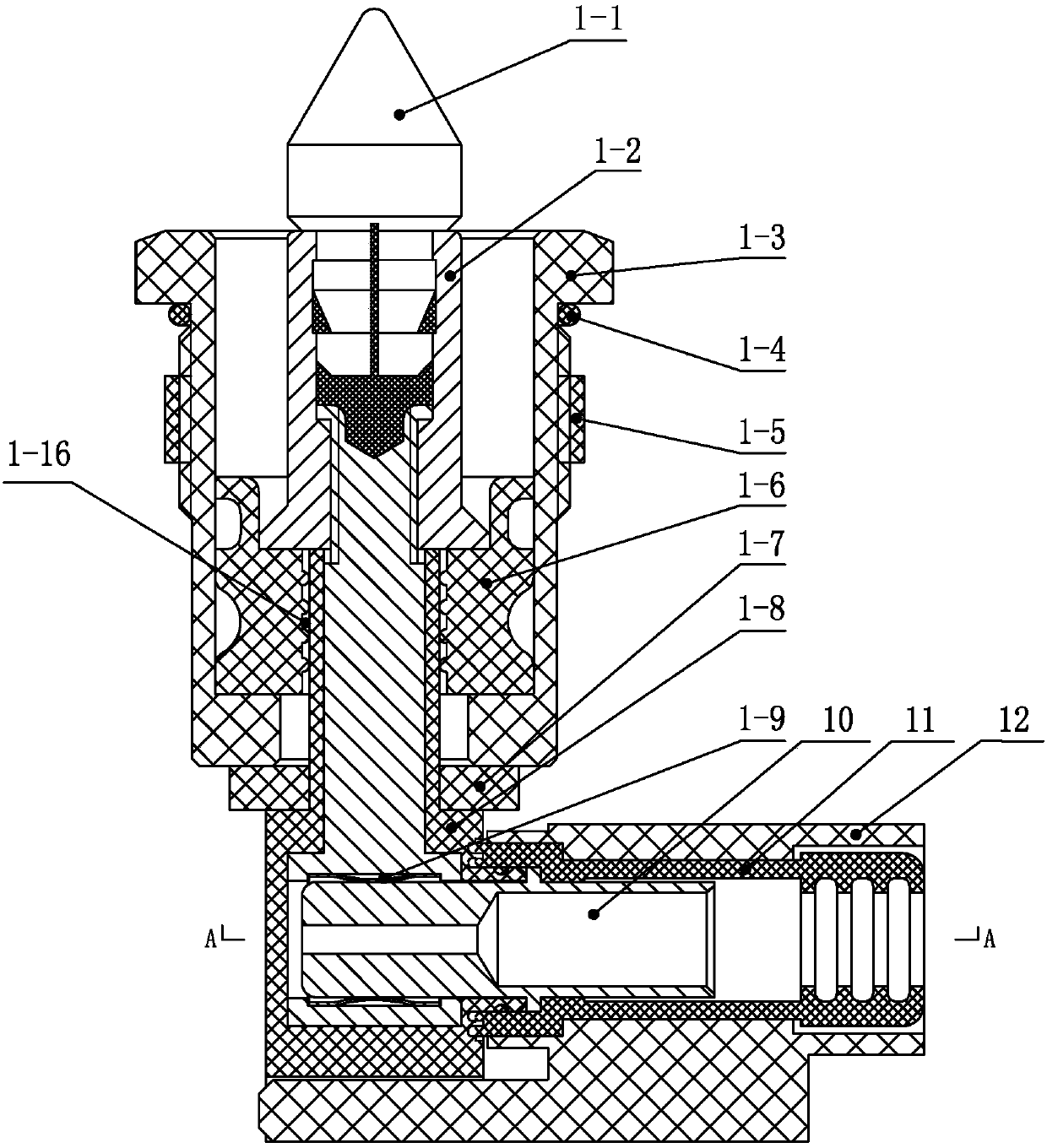

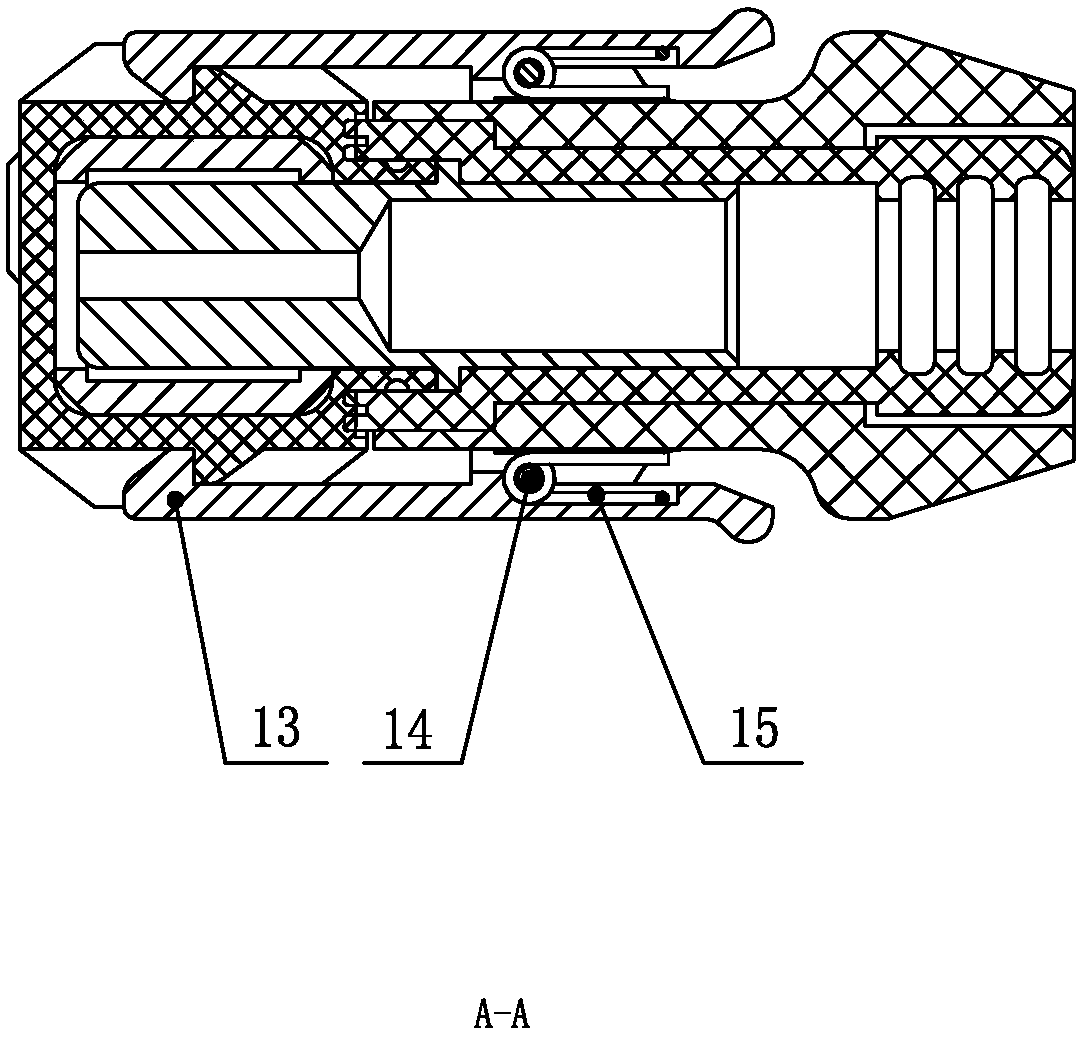

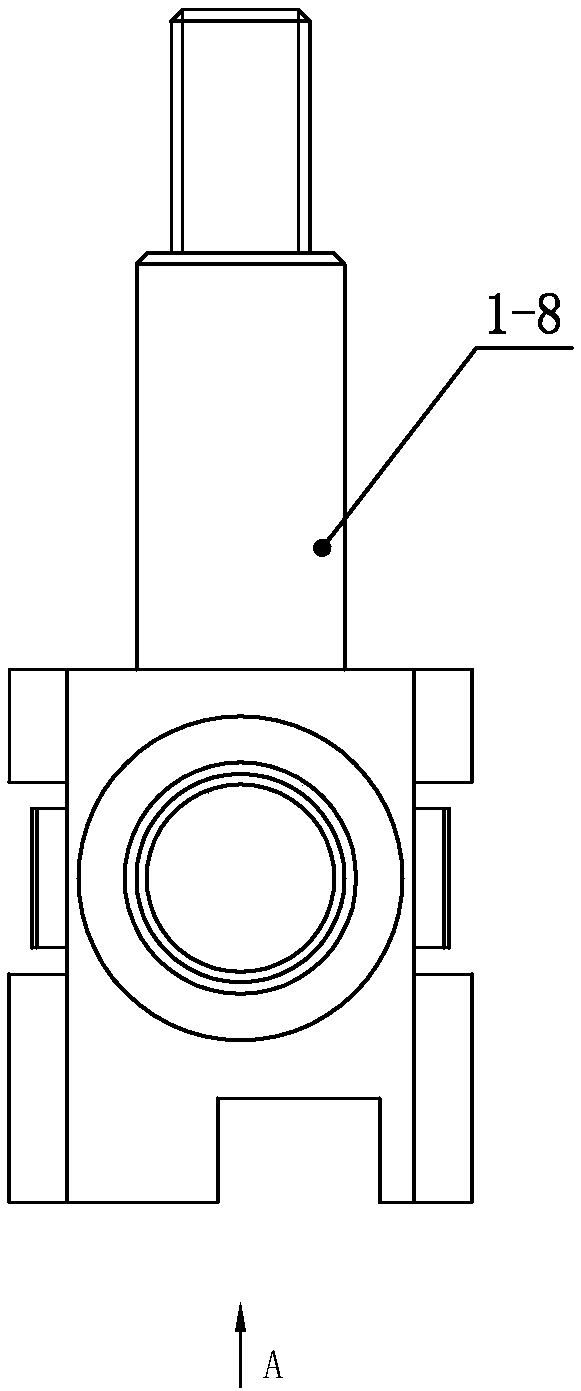

[0052] Embodiment 1: as Figure 1 to Figure 32 As shown, the wiring quick termination mechanism includes an electrical connector, and the electrical connector in this embodiment is a socket (structure such as Figure 1-Figure 23 shown) or plug (structured as Figure 24-31As shown), one end of the electrical connector is provided with a plug-in device for external plugging, the other end is provided with a terminal connected to the cable, and a locking sleeve body 12 is provided, and the locking sleeve body 12 is provided with The conductor 10, in order to prevent the conductor 10 from falling off during use, a cable sealing ring 11 can also be provided between the locking sleeve body 12 and the conductor 10, and the locking sleeve body 12 is connected to the electrical connector through a locking mechanism The terminals can be detachably installed to achieve quick termination. The locking mechanism can be installed on the locking sleeve body 12 or at the terminals on the elec...

Embodiment 2

[0072] Embodiment 2: the feature that differs from embodiment 1 in the present embodiment is: as Figure 33 As shown, there are multiple locking hooks 13 in the locking mechanism, and the locking hooks 13 are installed on the locking sleeve body 12, and the electrical connector forms a card slot matching the locking hooks 13. In the locked state, The locking hook 13 is snapped into the slot on the electrical connection.

[0073] When the conductor 10 is connected, the locking hook 13 shrinks toward the middle. After the conductor 10 is inserted in place, the locking hook 13 returns to its original state, and the locking hook 13 is clamped on the electrical connector. When the conductor 10 is pulled out, it shrinks. Lock hook 13, can pull out conductor 10.

Embodiment 3

[0074] Embodiment 3: the difference between this embodiment and the above-mentioned embodiment is: as Figure 34As shown, the locking mechanism includes a locking ring 18, which is connected to the locking sleeve body 12, and a rotatable steel ball 17 is arranged between the locking sleeve body 12 and the locking ring 18, and the conductor 10 is inserted into the , the locking sleeve body 12 and the locking ring 18 move towards the direction of the electrical connector, the steel ball 17 is clamped between the opening of the locking ring 18 and the locking sleeve body 12, and the locking ring 18 is away from the electrical connector A fixed ring 20 is formed at one end of the fixed ring 20, and a spring 19 is provided between the fixed ring 20 and the locking sleeve body 12. When the conductor 10 is inserted, the locking ring 18 compresses the spring 19 to move in the opposite direction of the electrical connector, and as the locking The sleeve body 12 continues to move toward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com