Aircraft fairing mold and using method

A technology for fairings and aircraft, applied in the field of composite material molding molds, can solve the problems of scrapping composite material parts, and achieve the effects of simplified mold structure, easy operation, and simplified mold clamping operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

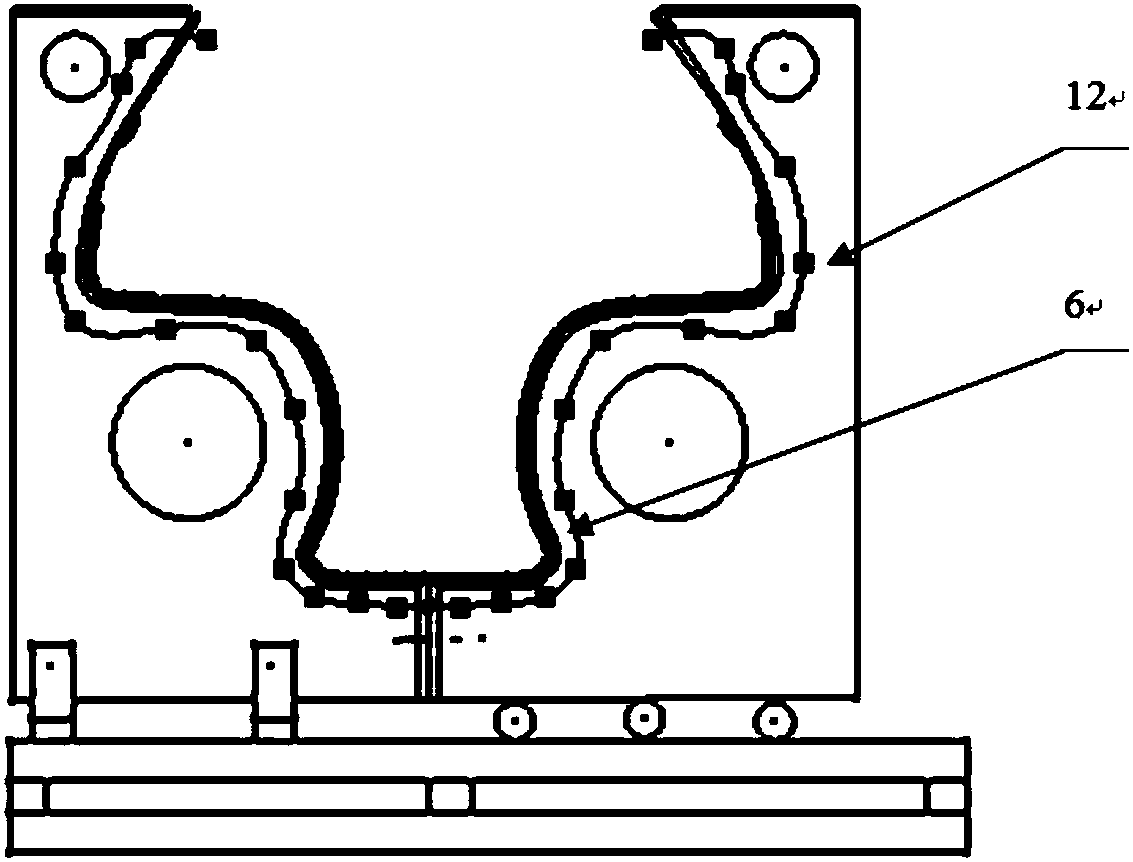

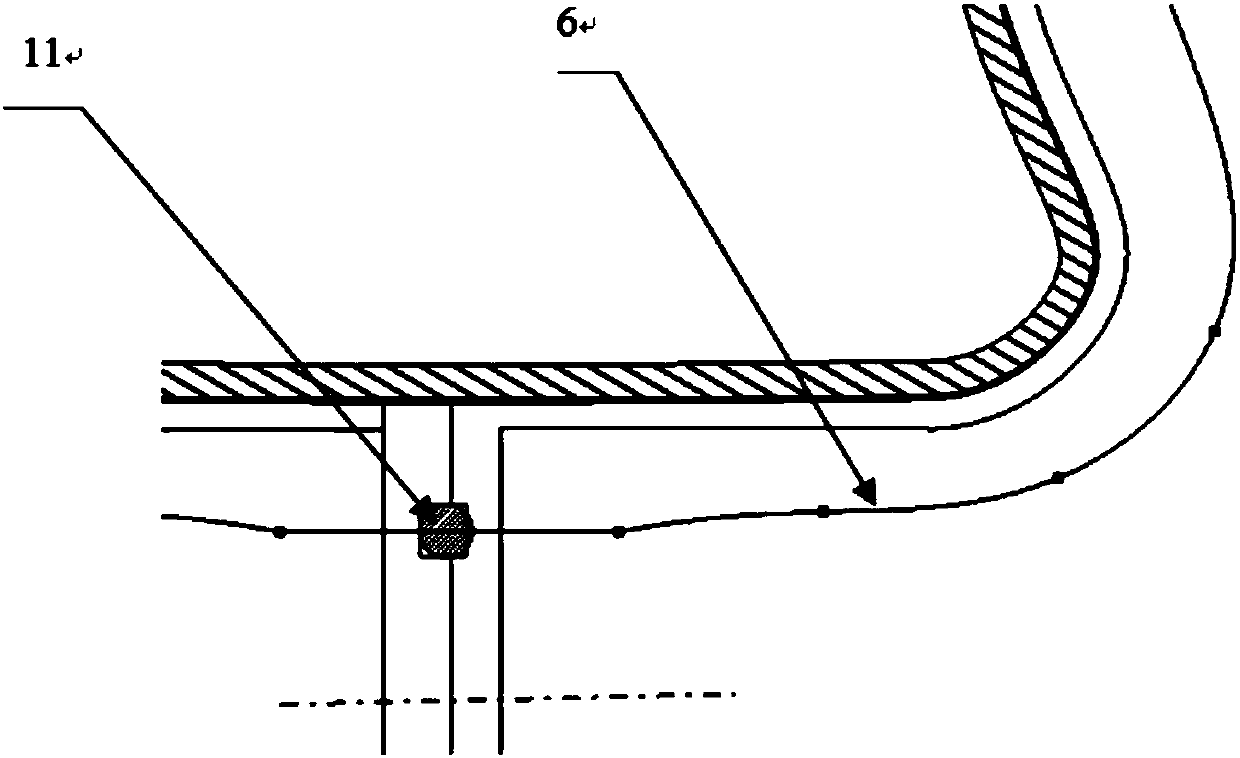

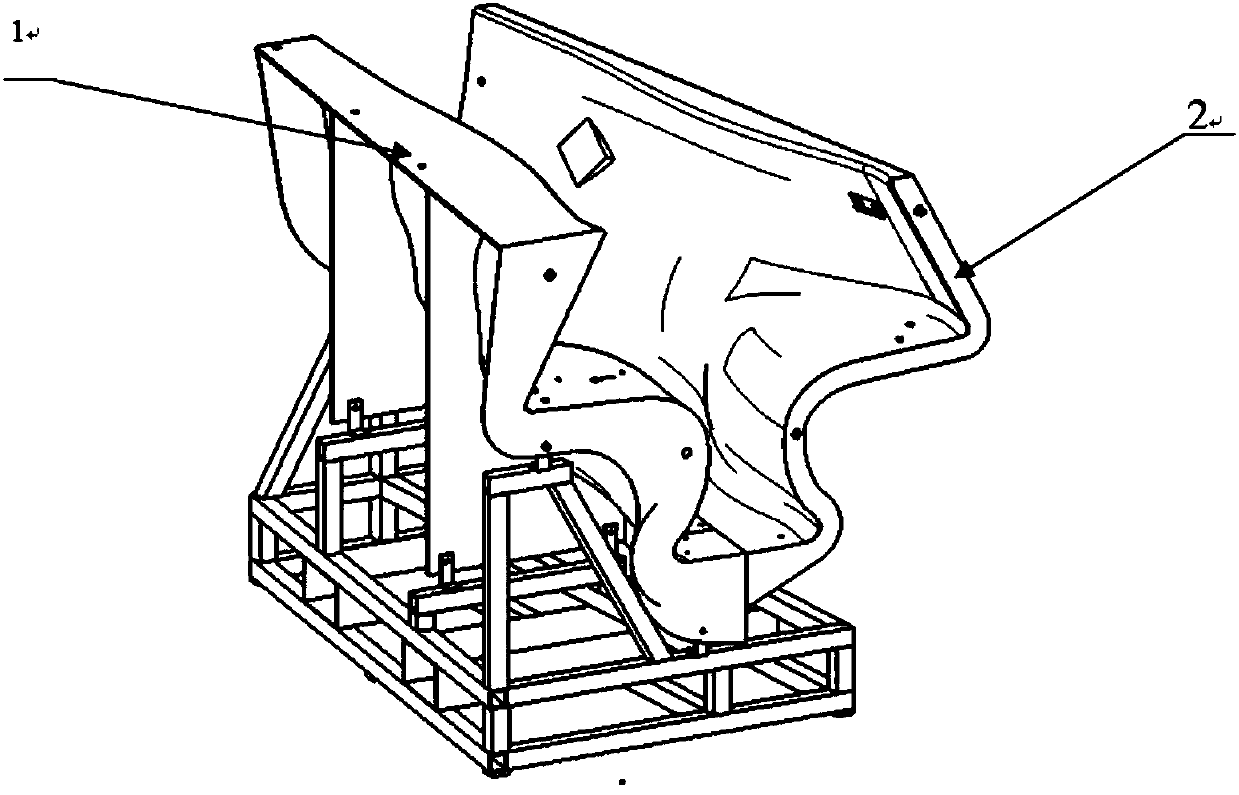

[0025] The invention provides a kind of aircraft fairing mould, and mold comprises main mold body 1 and sub-mould body 2; The mating surface flanging 3 of body is longer than the mating surface flanging 4 of sub-mould body, and the mating surface flanging of main mold body and the mating surface flanging of sub-mould body form step shape after the mold closing, and main mold body The stepped surface 5 of the main mold body is used to fix the vacuum bag 6, and there are bolt through holes 7 and pin through holes 8 on the flange of the clamping surface of the sub-mould body, corresponding to the bolt through holes 8 on the flange of the clamping surface of the main mold body. The positions of the hole and the pin through hole are buried with threaded sleeve 9 and bushing 10 respectively.

[0026] The using method of mold of the present invention, its specific process is as follows:

[0027] Step 1. Mold closing

[0028] Position the sub-model body and the main model body of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com