Pressing and flattening device for golden camellia compression packing

A technology of camellia tea and pressing plate, which is applied in the field of flattening devices and compression packaging of camellia camellia, which can solve the complicated troubles of device design, the inability to pre-wet, and the poor control of the pressure of camellia camellia flattening, etc. problem, to achieve the effect of improving efficiency and improving flattening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

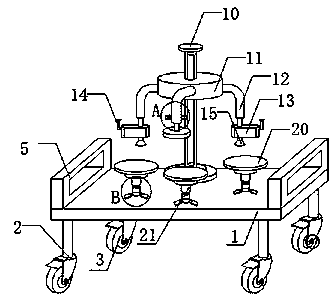

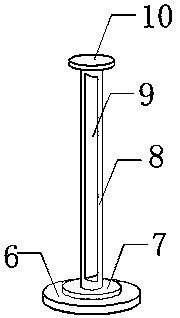

[0026] see Figure 1-6 As shown, a flattening device for compression packaging of golden camellia, including a workbench 1, a universal wheel 3, a bottom plate 6, a rotating shaft 7, a chute 9, a shaft arm 12, a nozzle 15, a chassis 20 and a movable part 24, A base plate 6 is arranged in the center of the workbench 1, and a rotating shaft 7 is arranged in the center of the base plate 6. A column 8 is connected to the rotating shaft 7, and a chute 9 is embedded on the column 8. By setting the chute 9 on the column 8, the installation The plate 11 will slide up and down on the chute 9, and then drive the pressure plate 17 to slide up and down. In this way, it will have a flattening effect on the golden camellia placed on the chassis 20, and the flattening of the golden camellia. It is not only uniform but also saves time and effort, and improves the flattening efficiency of camellia japonica, and the mounting plate 11 is sleeved on the column 8, and the top of the column 8 is pr...

Embodiment 2

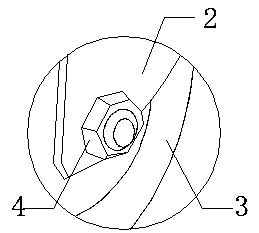

[0028] read on Figure 1-6 As shown, the difference from the above embodiment is that the four corners of the bottom end of the workbench 1 are provided with legs 2, the bottom ends of the legs 2 are connected with universal wheels 3, and the legs 2 are fastened by fastening screws 4 The universal wheels 3 are connected, and push handles 5 are arranged on both sides of the workbench 1. By setting the universal wheels 3, the device is convenient for the operator to move it. The bottom end of another group of shaft arms 12 is connected with a telescopic rod 16, and the bottom end of the telescopic rod 16 is positioned at the top of the pressure plate 17, and the telescopic rod 16 is partially positioned inside the shaft arm 12, and the telescopic rod 16 is positioned on the shaft arm 12. The inner part is also embedded with a chute 9, and by setting the telescopic rod 16, the telescopic rod 16 can adjust its length twice. The telescoping rod 16 runs through the chute 9 on the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com