Hybrid power vehicle clutch control method and device

A hybrid vehicle and clutch control technology, applied to clutches, mechanical equipment, etc., can solve problems affecting user experience, inability to achieve high-precision clutch control, and degradation of shifting quality and mode switching quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0045] In the clutch control, due to the manufacturing deviation of the clutch, the manufacturing deviation of the execution system, the wear and aging of the clutch during use, and the wide variety of use environments, it will cause the clutch to use a fixed control characteristic curve and cannot achieve accurate clutch control under all circumstances. control. The off-line self-learning of the gearbox or the self-learning of the clutch characteristic curve of simple variables used in the prior art cannot realize the high-precision control of the clutch in a complex environment.

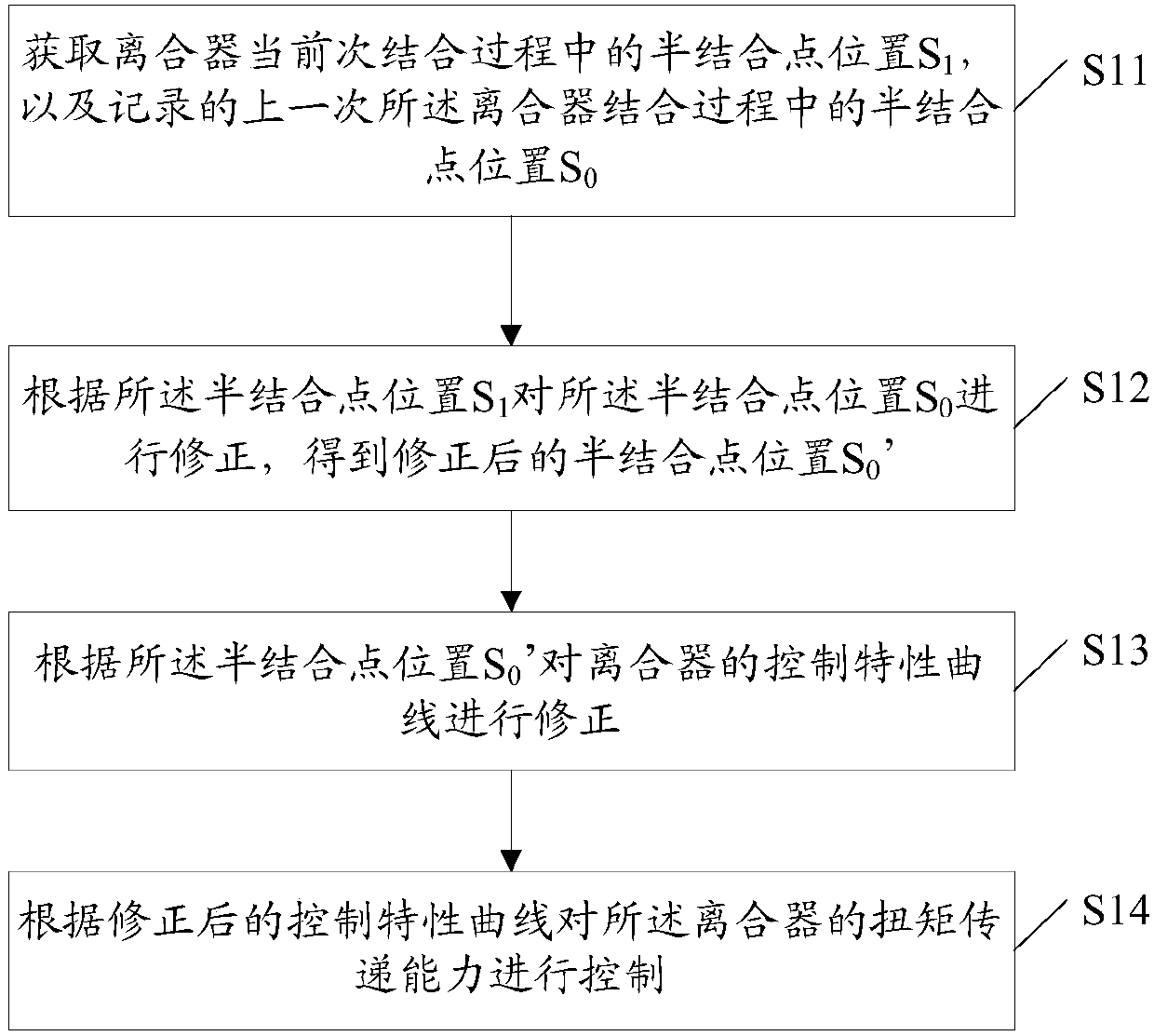

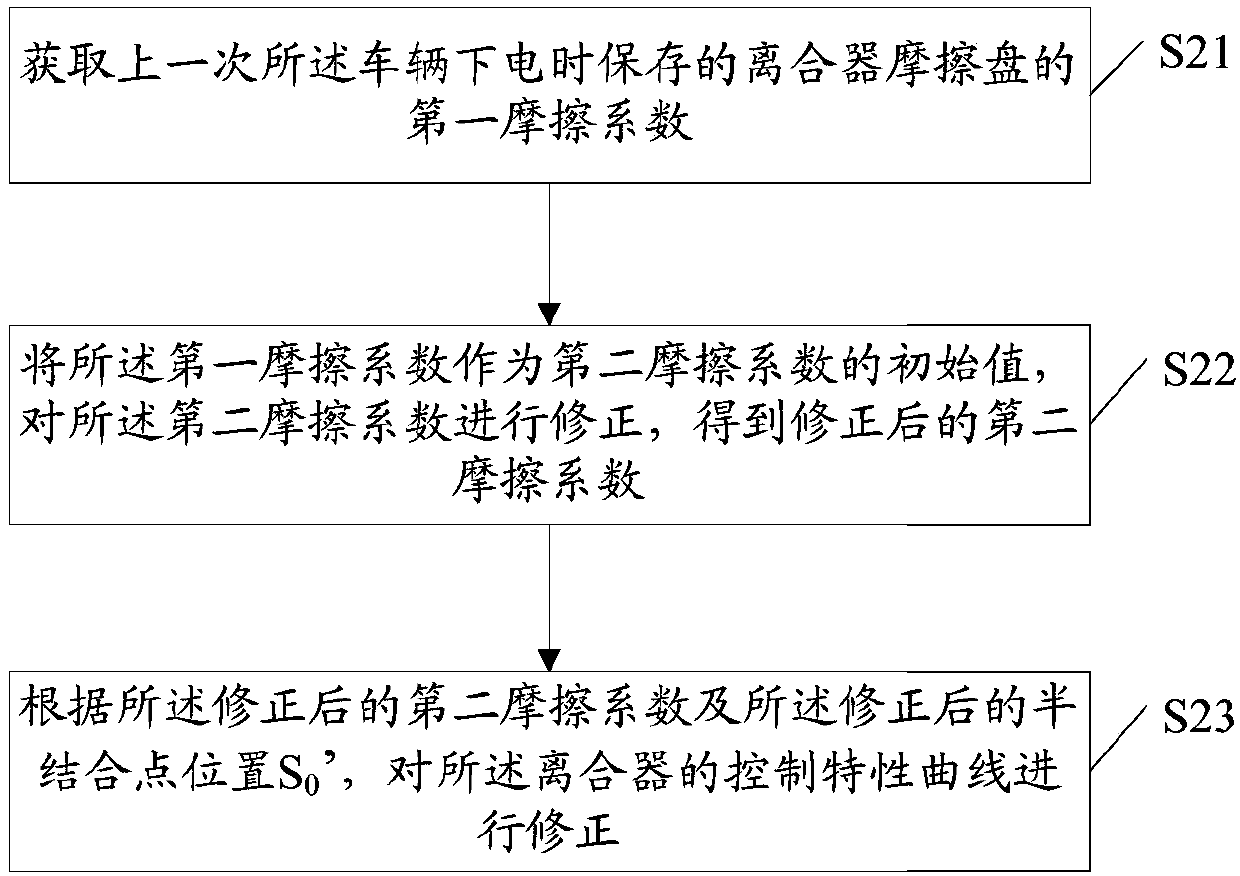

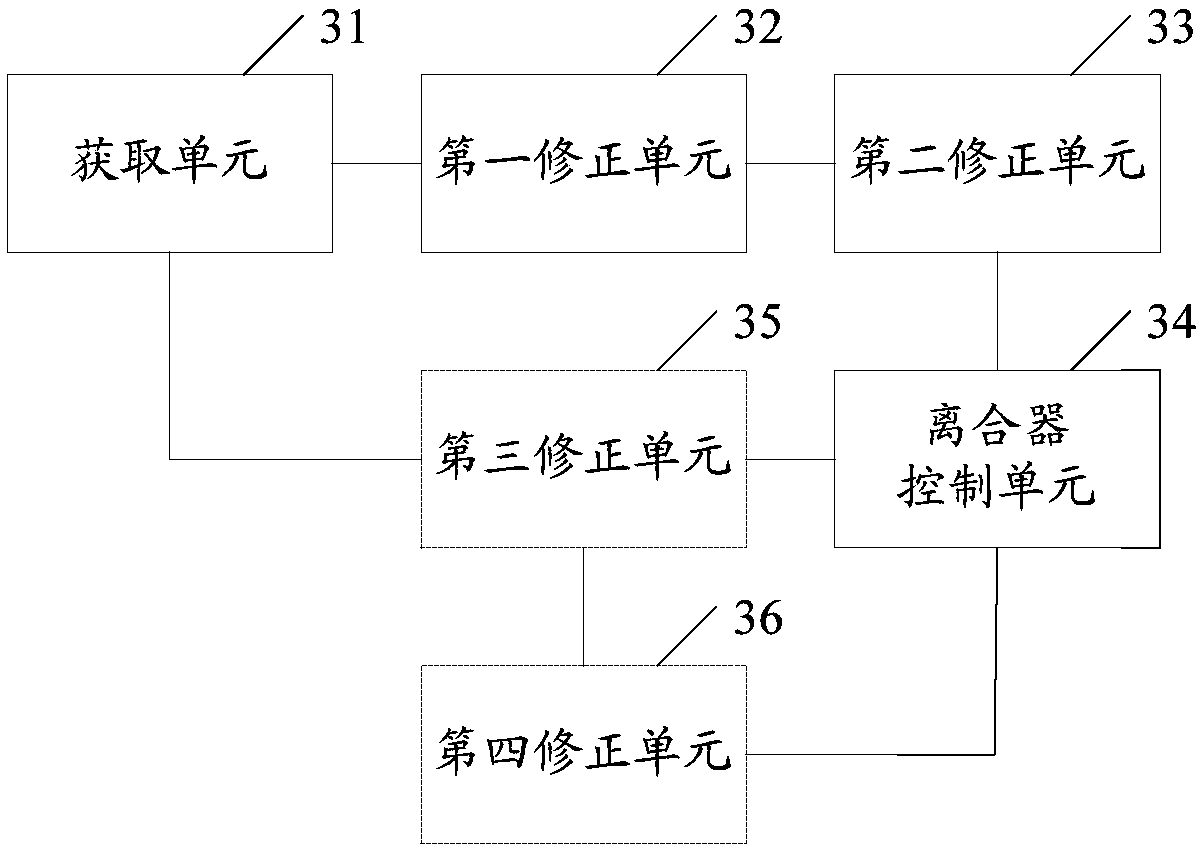

[0046] In the embodiment of the present invention, the position S of the half-engagement point in the current engagement process of the clutch is obtained 1 , and the recorded half-engagement point position S during the last clutch engagement process 0 , and according to the half-binding site position S 1 For the half-binding site position S 0 Make corrections to obtain the corrected half-joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com