Sealing ring and the use thereof

A technology of sealing ring and sealing lip, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of not being installed, and achieve low-cost manufacturing, low assembly cost, reliable positioning and long-lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

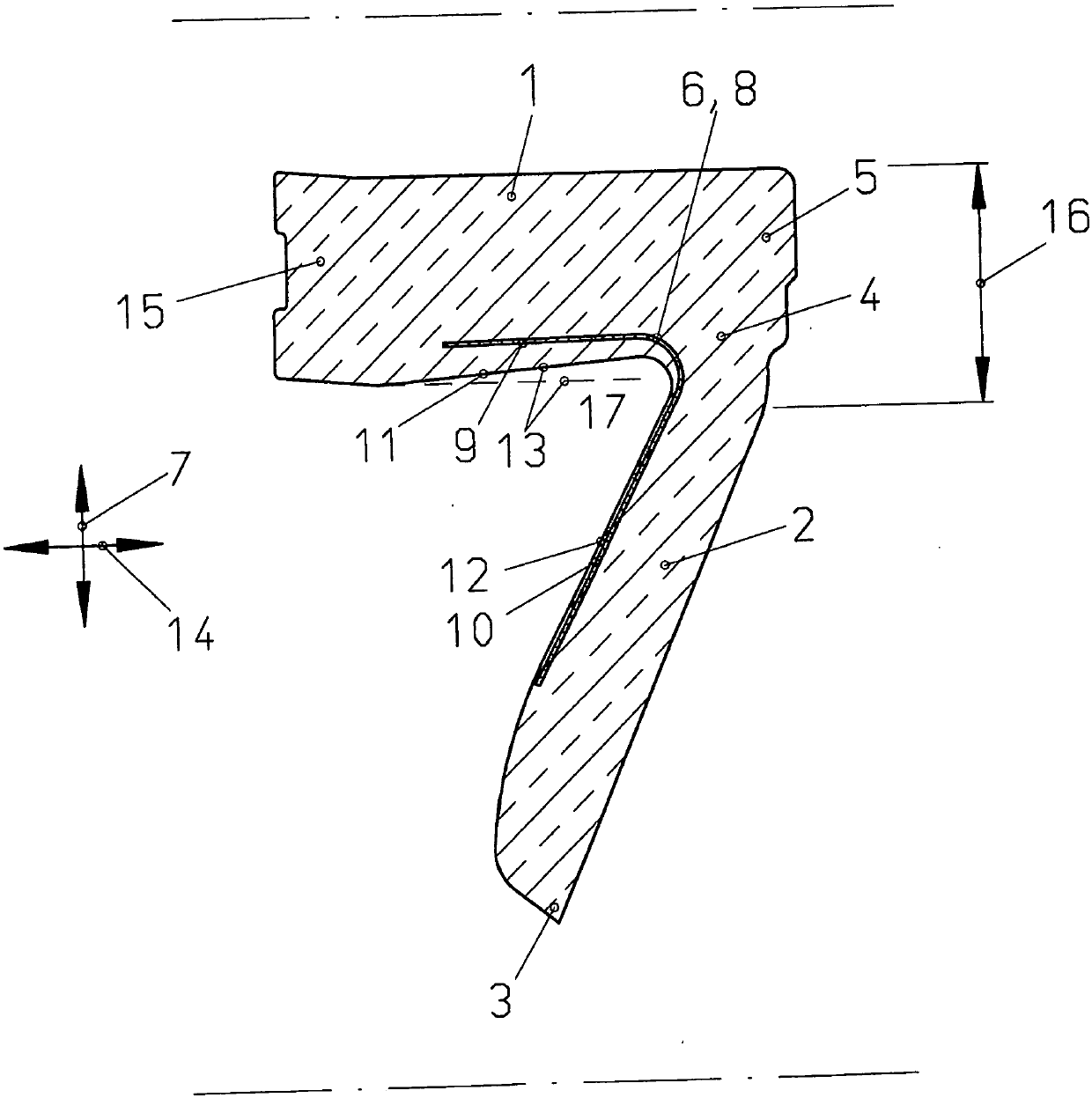

[0028] exist figure 1 The sealing ring shown in FIG. 2 is designed in the shape of a 7 and has, as tensioning element 6 , a likewise 7-shaped spring 8 which forms an integral component of the sealing ring and is completely surrounded by the sealing material of the sealing ring.

[0029]The sealing ring comprises a first axial leg 1 and a sealing leg 2 with a sealing lip 3 , wherein, depending on the application, the sealing leg 2 and the sealing lip 3 are arranged radially inside or radially outside of the sealing ring. Two axes of symmetry radially adjacent to the sealing lip 3 or radially adjacent to the first axial leg 1 are shown schematically. The sealing leg 2 is articulated on the first end side 5 of the axial leg 1 by means of an articulation joint 4 , wherein the joint 4 is arranged as far as possible from the sealing lip 3 in the radial direction 7 in order to be able to balance also here The large eccentricities of the machine elements are shown. This large eccent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com