High-precision gas density relay

A gas density, relay technology, applied in the direction of circuits, electric switches, electrical components, etc., can solve problems such as poor anti-vibration performance, difficulty in ensuring reliable and safe operation of the power grid, and poor contact contact, so as to improve product adaptability and facilitate combination The effect of production and easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

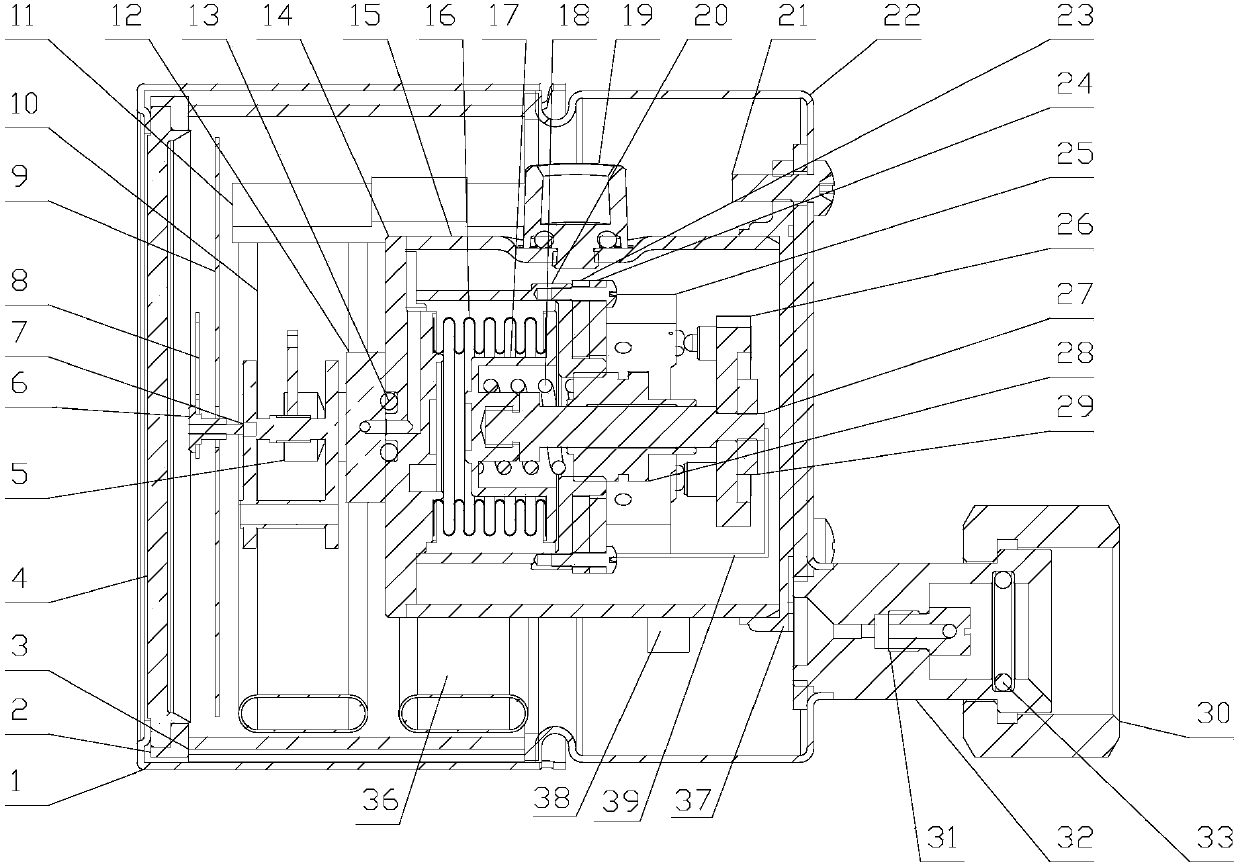

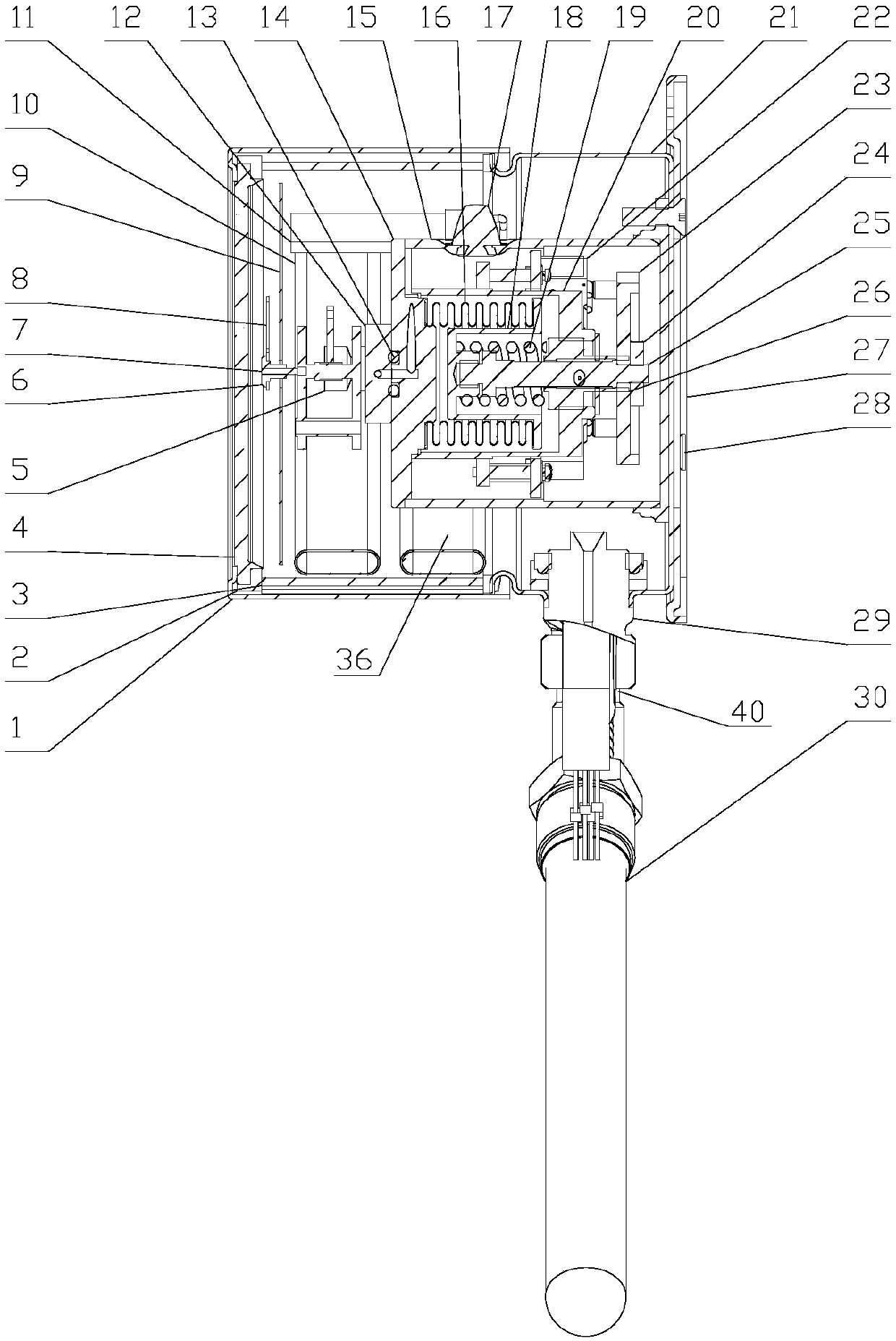

[0033] figure 1 and figure 2 It is a partial cross-sectional schematic diagram of a high-precision gas density relay according to Embodiment 1 of the present invention, as figure 1 and figure 2 As shown, the high-precision gas density relay of Embodiment 1 of the present invention includes: a watch case 22 , located inside the watch case 22 ,...

Embodiment 2

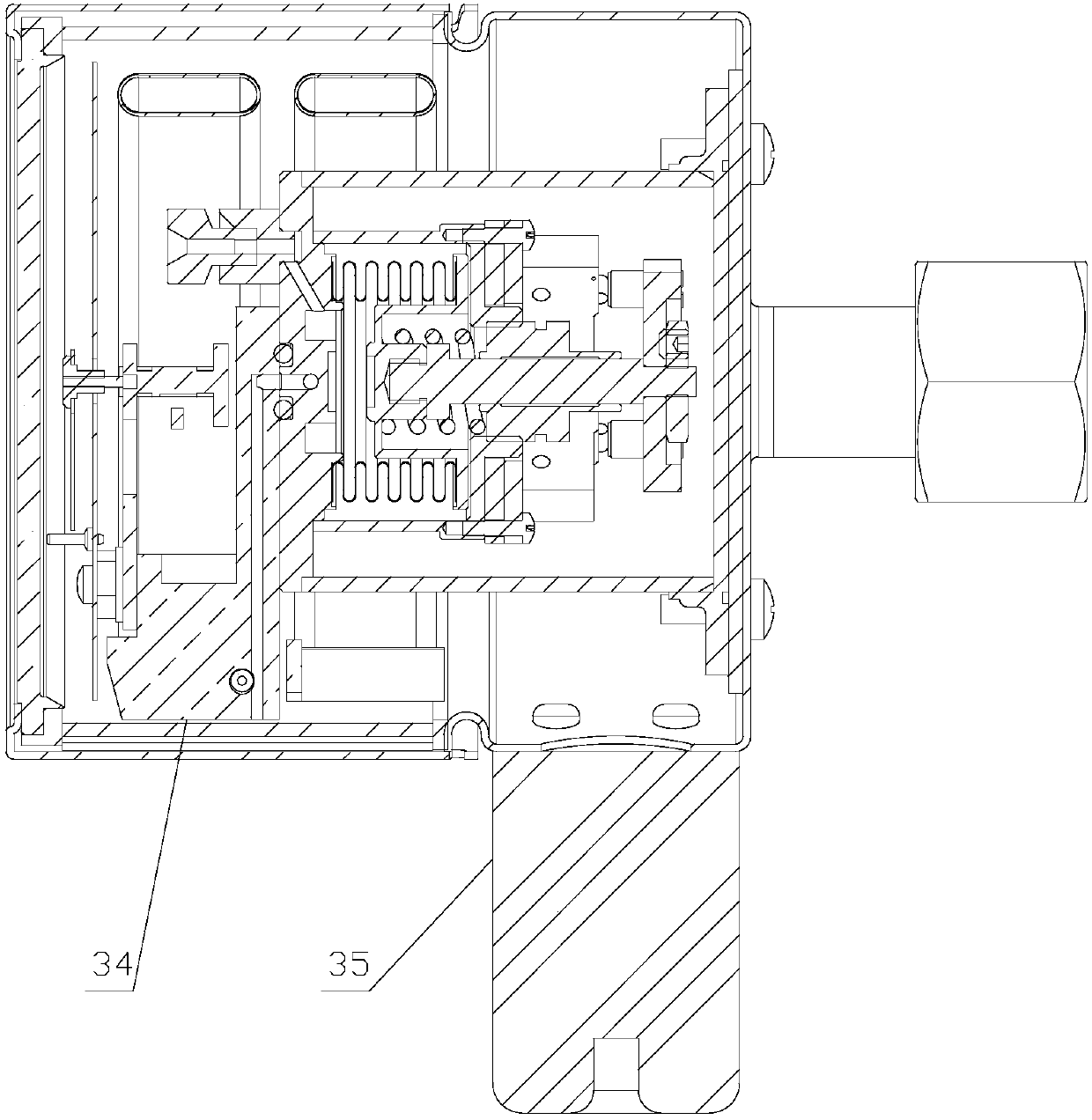

[0048] image 3 and Figure 4 It is a partial cross-sectional schematic diagram of a high-precision gas density relay according to Embodiment 2 of the present invention, as image 3 and Figure 4 As shown, the high-precision gas density relay of Embodiment 1 of the present invention includes: a watch case 22 , located inside the watch case 22 , a signal mechanism and an indication display mechanism that communicate with each other, and the signal mechanism is fixedly installed on the inner surface of the watch case 22 .

[0049] The signal mechanism is a sealed air chamber surrounded by the chassis 14, the housing 15 and the bottom plate 37, and the bellows 16 and the alarm assembly located inside the sealed air chamber. The bellows 17 controls the on or off of the micro switch assembly, and the sealed The gas chamber communicates with the display Baden tube 10 in the indication display mechanism.

[0050] One end of the bellows 16 is sealed and welded to the chassis 14, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com