Glass steel pipe fitting with quick splicing structure and preparation method and device

A technology of fast splicing and glass steel pipes, which is applied in the direction of connecting components, grinding drive devices, and parts of grinding machine tools, etc. It can solve the unfavorable construction and production of glass steel pipe parts, the inconvenience of fast splicing work of glass steel pipe parts, and the inconvenience of grinding-positioning-winding and other problems, to achieve the effect of surface smoothing treatment, convenient positioning and processing, and convenient processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

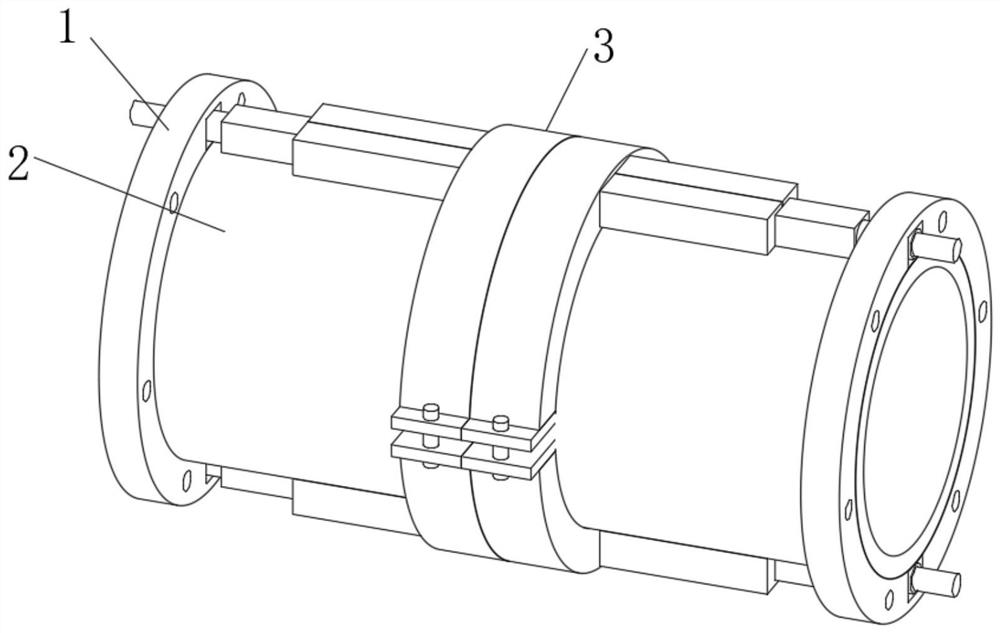

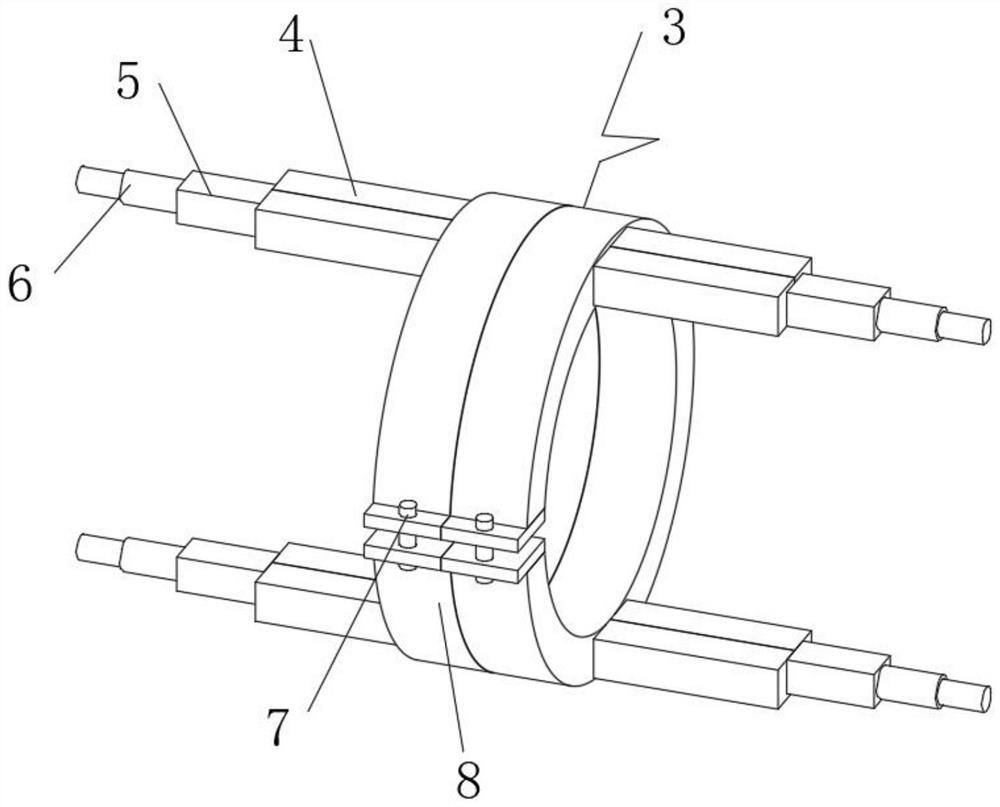

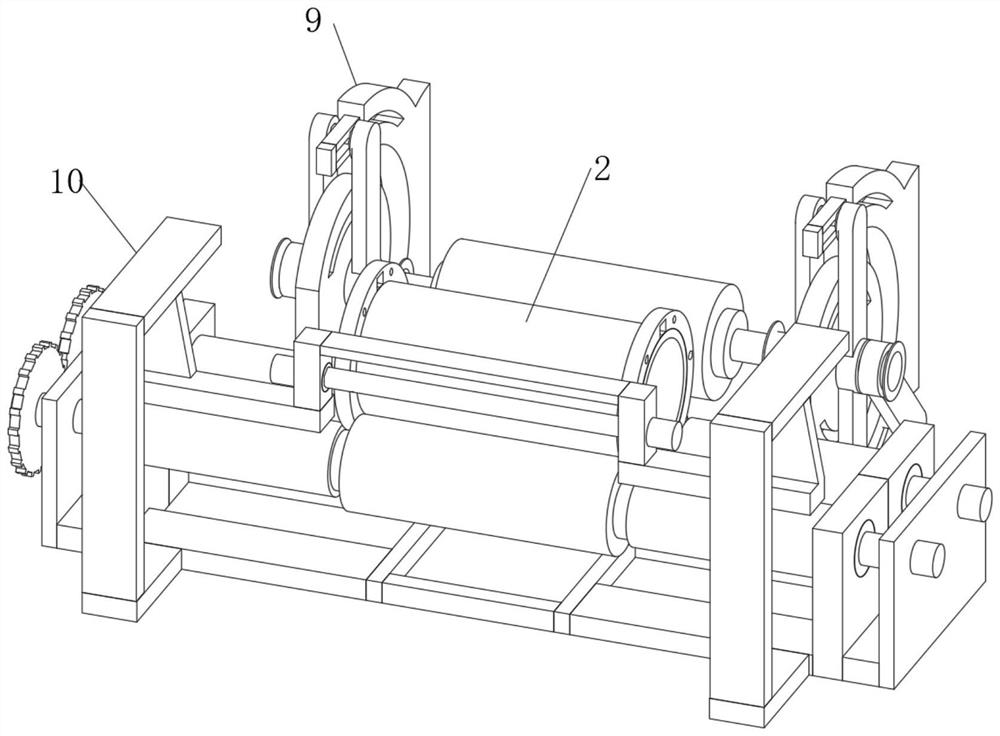

[0052] see figure 1 , figure 2 , an embodiment provided by the present invention: a glass steel pipe fitting with a quick splicing structure, a preparation method and a device, comprising a glass steel pipe sleeve 1, a glass steel pipe lining 2 and a connecting structure 3, and the lower end of the glass steel pipe sleeve 1 is fixedly connected with a FRP lining 2, the central position of the FRP lining 2 is limitedly connected with a connecting structure 3, and the connecting structure 3 includes a stable limiting frame 4, a spring inner groove frame 5, a push connection end frame 6, a plug-in pin body 7 and a socket connection Socket 8, the socket socket 8 is located at the center position of the inner end of the connection structure 3, the front end position of the socket socket 8 is inserted with a plug-in pin body 7, and the side end position of the socket socket 8 is fixed with the stable limiting frame 4 Connection, the side end position of the stable limiting frame 4...

Embodiment 2

[0066] On the basis of Example 1, as Figure 10 As shown, the front end position of the production and processing structure 10 is provided with an air extraction groove pipe 30, the front end position of the air extraction groove pipe 30 is communicated with a communication matching pipe 31, and the side end position of the communication matching pipe 31 is communicated with an air exhaust connection pipe 32.

[0067] In the implementation of this embodiment, the user can perform the adsorption treatment of excess glass fibers by installing the air extraction groove pipe 30, the communication matching pipe 31 and the air extraction connecting pipe 32. It can avoid external pollution, and at the same time, it can carry out the purpose of conveying and discharging waste and waste, which can better carry out the purpose of environmental protection production and facilitate the overall processing and production.

[0068] A preparation method of a glass steel pipe fitting with a qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com