Precision feeding system for sows

A precision and sow technology, which is applied in the field of sow precision feeding system, can solve the problems of feed waste, labor-intensive, and low quantification accuracy in pig farms, so as to improve the level of automation and refinement, and benefit healthy growth and breeding, the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

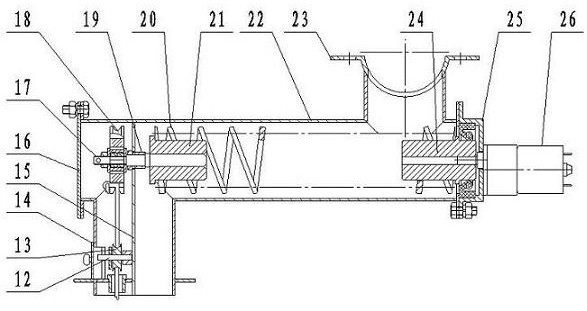

[0011] The present invention is further explained below with reference to the drawings: the sow reflection feeding system is made from sealant balls (1), pulling (2), refractory bouques (3), slings (4), electronic weighing sensors (5), give Supplemers (6), automatic material wire feed tube (7), upper semi-circular (8), electrical control system (9), electric wire (10), computer (11), etc., wherein the feeder (6) is By optical axis (12), guide wheel (13), threading door (14), discharge plate (15), end cap (16), a scorpion head shaft (17), a ratchet assembly (18), sliding shaft Set (19), twinkling (20), over-axle (21), feed tube welding (22), lower semi-circular kon (23), drive hub (24), motor flange (25), DC deceleration Motors (26) and the like. The intensive bucket (3) is a circular spray-shaped container, which is designed with a circular injection port. There is a circular discharge opening, a hanging rope (4) symmetrical arrangement in the intensive bucket (3), lower end and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com