Tibial tunnel traction suture guide cannula for arthroscopic posterior cruciate ligament reconstruction

A cruciate ligament and traction wire technology, applied in the field of medical devices, can solve the problems of time-consuming operation, difficulty in wire manipulation, and increase in surgical incisions, and achieve the effects of reducing the risk of vascular and nerve damage, saving operation time, and simplifying operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

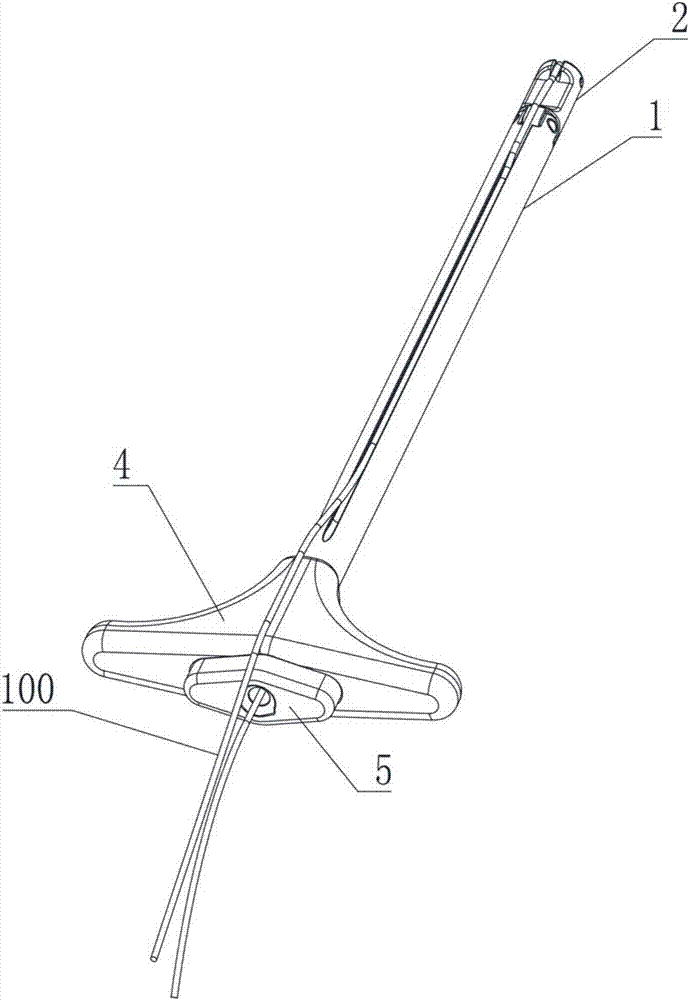

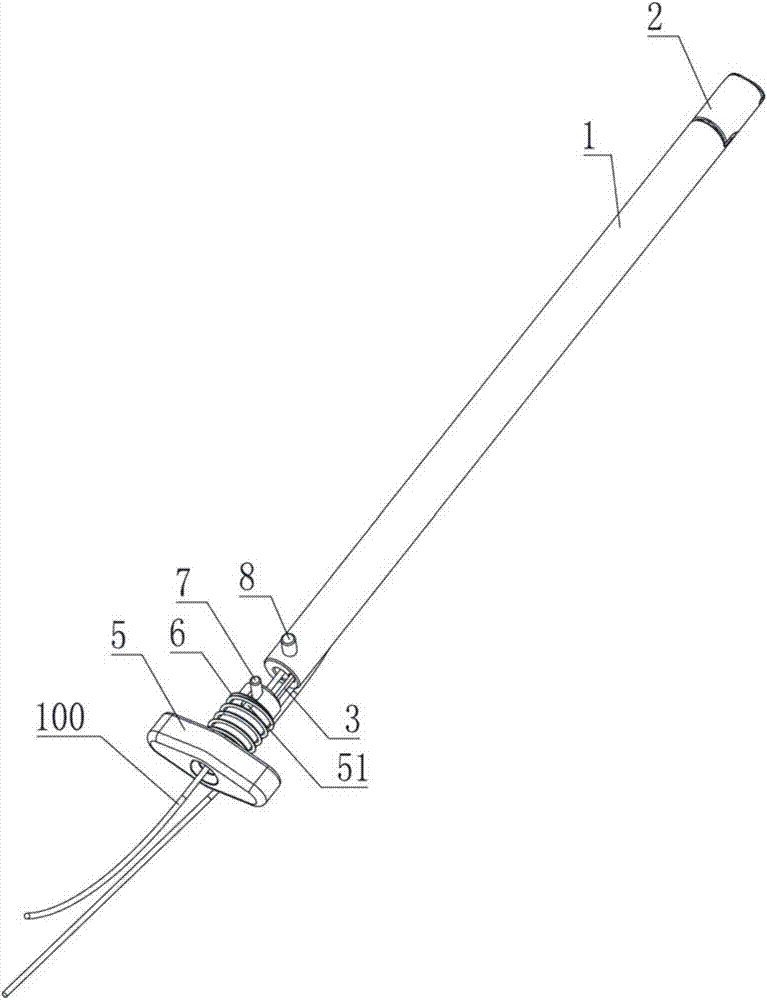

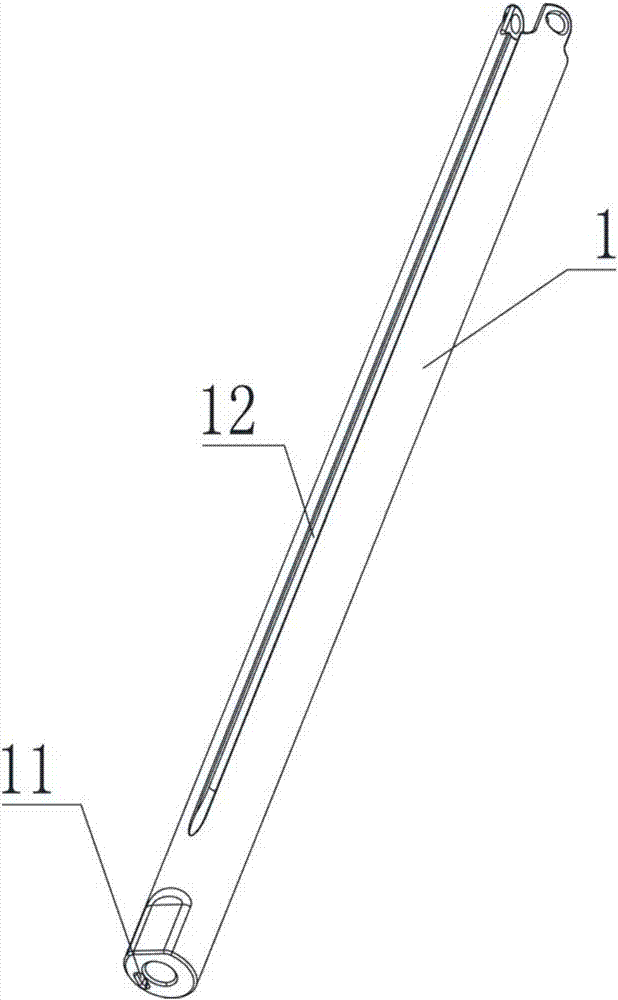

[0038] like Figure 1-Figure 3 As shown, the arthroscopic posterior cruciate ligament reconstruction tibial tunnel traction wire guide sleeve provided by the embodiment of the present invention includes a wire-passing sleeve 1, a hinged section 2 and a first push rod 3, wherein the hinged section 2 and the wire-passed sleeve The pipe 1 is hinged and can rotate relative to the wire-passing sleeve 1. The pipe wall of the wire-passing sleeve 1 is provided with a first push rod groove 11 arranged along the axial direction of the wire-passing sleeve 1, and one end of the first push rod 3 extends into the The first push rod slot 11 is capable of moving along the first push rod slot 11 , and the angle of rotation of the hinge section 2 relative to the wire-passing sleeve 1 is adjusted by using the length protruding from the first push rod slot 11 .

[0039] like figure 1 and Figure 4 As shown, the hinged section 2 is a hollow tube structure as a whole, and one end of the hinged se...

Embodiment 2

[0054] Such as Figure 7-Figure 11 As shown, the second embodiment is basically the same as the first embodiment, and the similarities will not be repeated. The difference is that the arthroscopic posterior cruciate ligament reconstruction tibial tunnel traction wire guide sleeve of this embodiment also includes a hinged transition section 9 and the second push rod 10, the hinged transition section 9 is a hollow tube structure, one end of which is hinged with the wire sleeve 1, and the other end is hinged with the hinged section 2, that is, the hinged transition section 9 is connected with the wire sleeve 1 and the hinged section at the same time. 2 hinged. A third push rod groove 91 corresponding to the first push rod groove 11 is provided on the hinged transition section 9. In an unbent state, the first push rod 11 passes through the first push rod groove 11 and the third push rod groove 11 in turn. Rod groove 91, when pushed forward, can be pressed against the hinged secti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com