Welding method for reducing overlapping joint defects of friction stir welding

A welding method and friction stir technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems affecting the performance and quality of joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

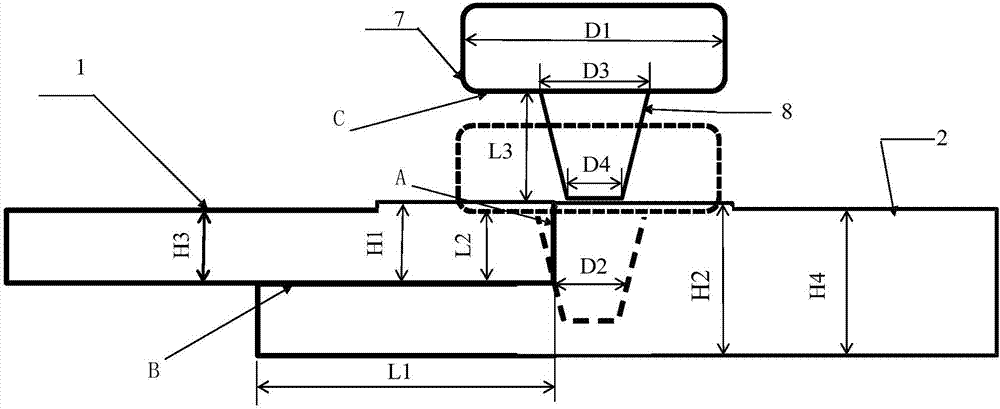

Embodiment 1

[0039] The aluminum alloy flat plate welded sheet 1 with H1=4mm and the aluminum alloy step welded sheet 2 with H2=6mm are assembled for the butt joint structure. The height of the butt joint surface is the same as that of H1, that is, 4mm. The surface length L1 is selected as 15mm, and then the friction stir welding is carried out using the welding method of the present invention: the stirring needle length L3=5.4mm, the pressing amount=0.2mm, the stirring needle root diameter D3=6mm, the end diameter D4=4mm, The diameter of the stirring needle at the junction of the bonding surface is D2=4.6mm, the shoulder diameter D1=18mm, the rotation speed is 800r / min, the welding speed is 200mm / min, and the distance between the agitating needle offset and the center of the bonding surface is 0.5×4.6mm =2.3mm. Microstructure analysis showed that there were no hook-shaped defects on the forward side of the joint, especially in the stirring zone on the backward side, no cold lap defects (su...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap