Laser marking machine

A laser marking machine and laser technology are applied in the field of laser marking machines to achieve the effects of being beneficial to structure, simplification and distance control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

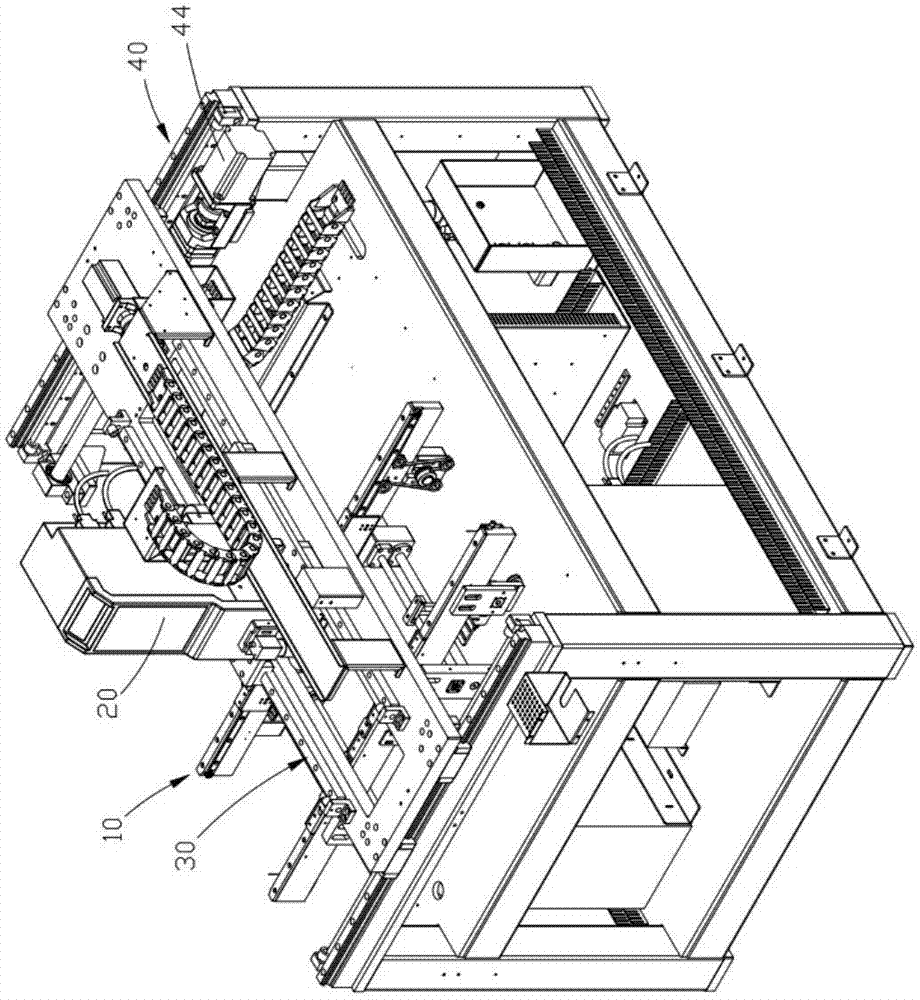

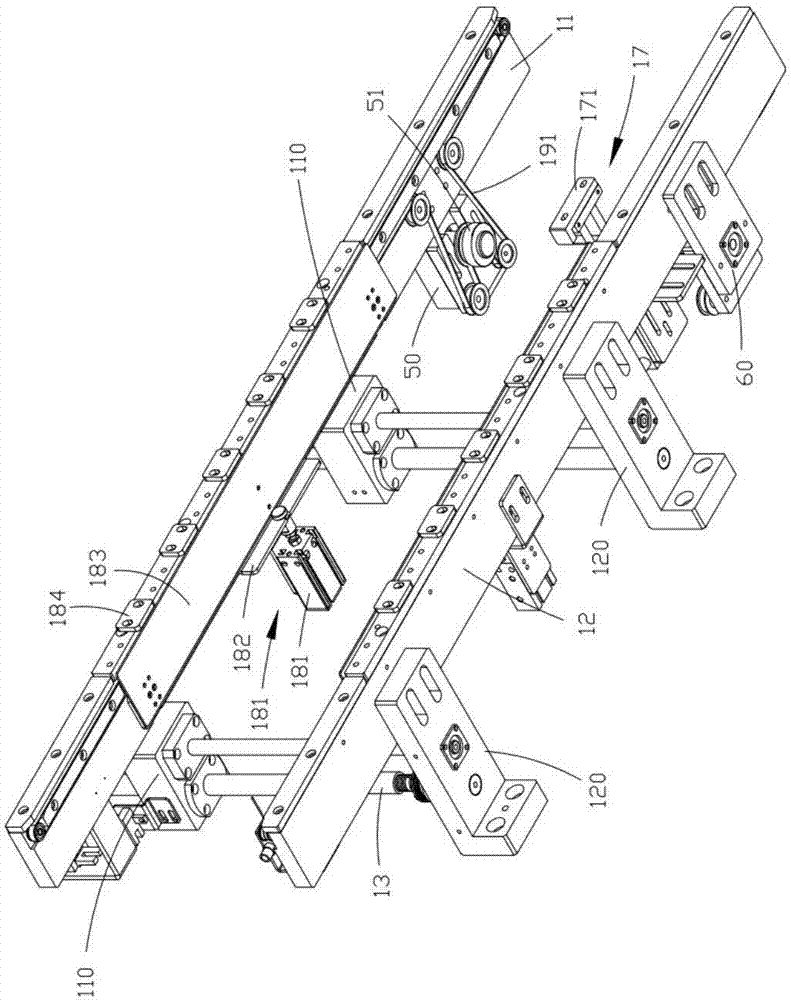

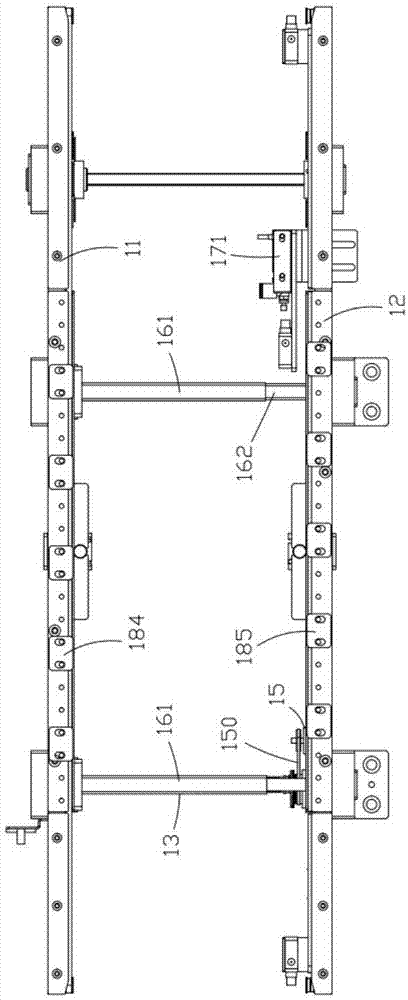

[0046] The following content reference Figure 1 to Figure 13 .

[0047] A laser marking machine, comprising a product transport track 10 and a laser 20 positioned above the product transport track, the product transport track includes a pair of support plates arranged side by side, a conveyor belt arranged inside the pair of support plates, a pair of support plates The second support plate 12 in the plate is fixedly arranged, and the first support plate 11 in a pair of support plates is installed on the transverse movement block 110, and the transverse movement block is provided with threaded sleeve 13, and threaded sleeve cooperates with screw rod 14, and screw rod It is connected with the transmission device a, and a guide assembly is arranged on the lateral moving block.

[0048] The second support plate 12 is installed on the support plate support 120, and the transmission device a is installed on the support plate support; the guide assembly includes a common sleeve 161...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com