An adjustable coaxial laser welding wire fixture device

A coaxial laser and welding wire fixture technology, which is applied in laser welding equipment, auxiliary equipment, welding equipment, etc., can solve the problems of easy falling protection effect of accessories, inconvenient adjustment of storage rack angle, etc., so as to improve the protection effect and improve the Protective range, increase the effect of using functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

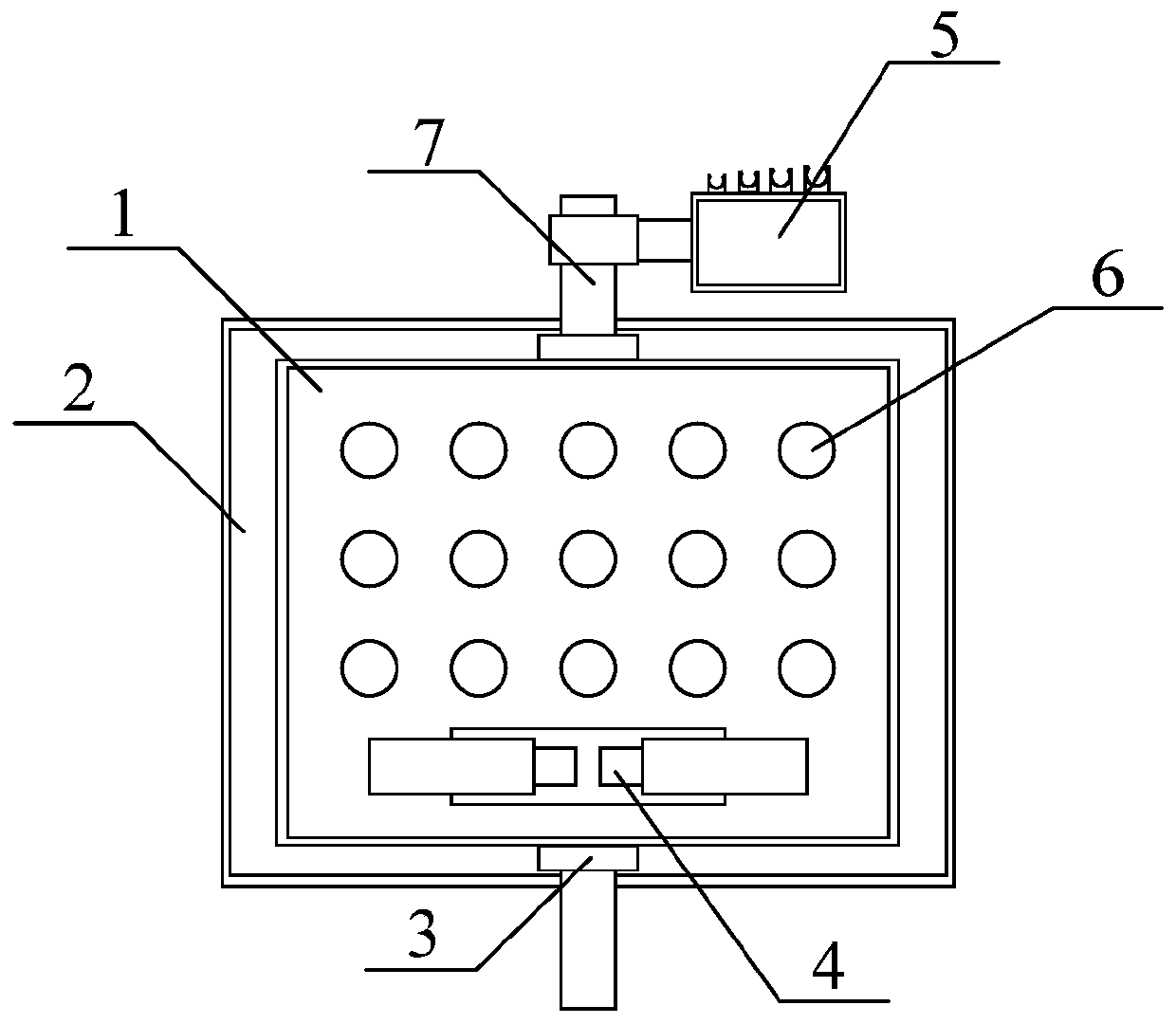

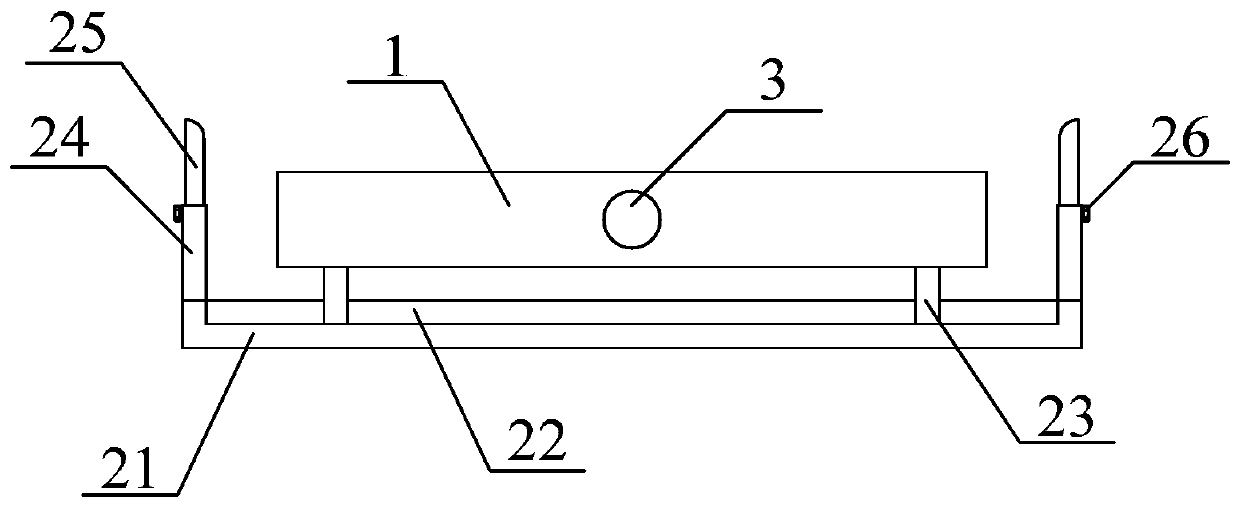

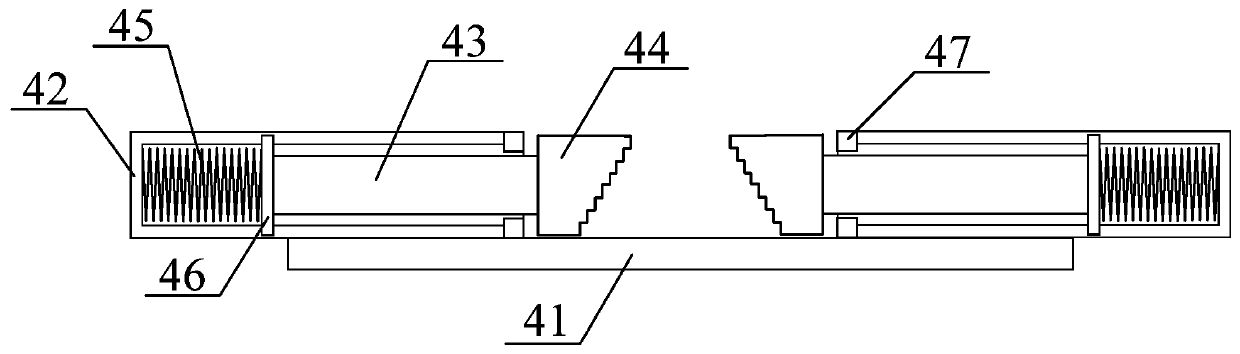

[0027] as attached figure 1 to attach Figure 4 shown

[0028] The invention provides an adjustable coaxial laser welding wire clamp device, which includes a base 1, a protective cover structure 2, a positioning block 3, a welding wire clamping device 4, an adjustable welding wire tool placement frame structure 5, and a loading channel. Holes 6 and positioning pins 7, the protective cover structure 2 is installed on the rear of the base 1; the welding wire clamping device 4 is fixed on the lower part of the front surface of the base 1; the loading through hole 6 is set on the front surface of the base 1; the positioning pin 7 is installed on the upper and lower ends of the middle position of the base 1 through the positioning block 3; the welding wire clamping device 4 includes a mounting plate 41, a clamping frame 42, pressing rod 43, clamping block 44, clamping spring 45, baffle plate 46 and stopper 47, described clamping frame 42 is fixed on the upper left and right sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com