Automatic lead seal feeding equipment for intelligent ammeter and work method adopting automatic lead seal feeding equipment

A smart meter, lead sealing technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of wasting manpower and material resources, poor lead sealing, damage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

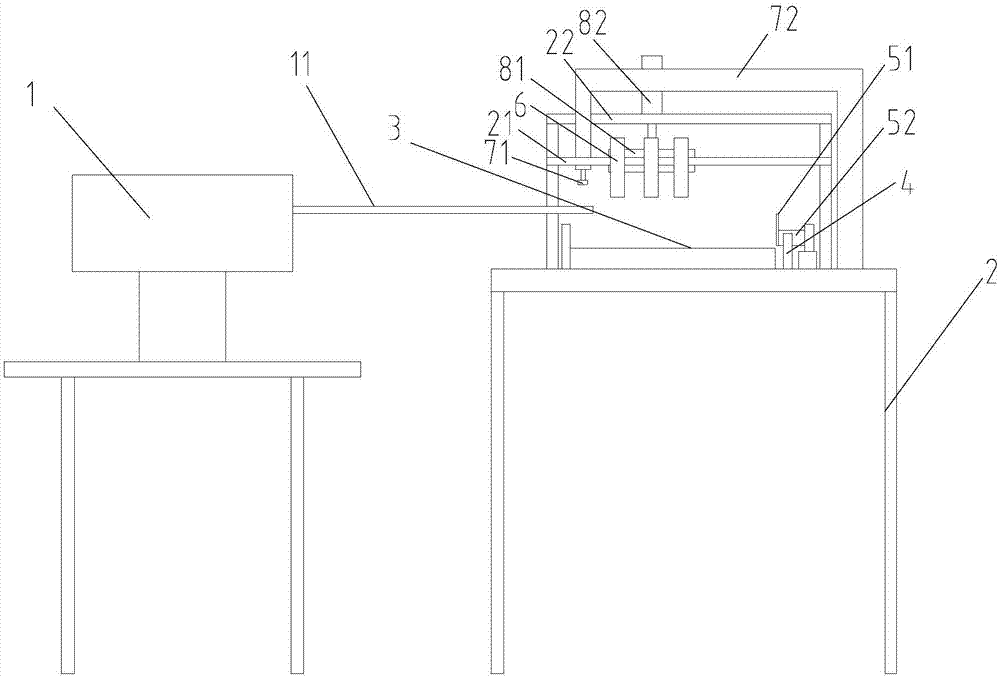

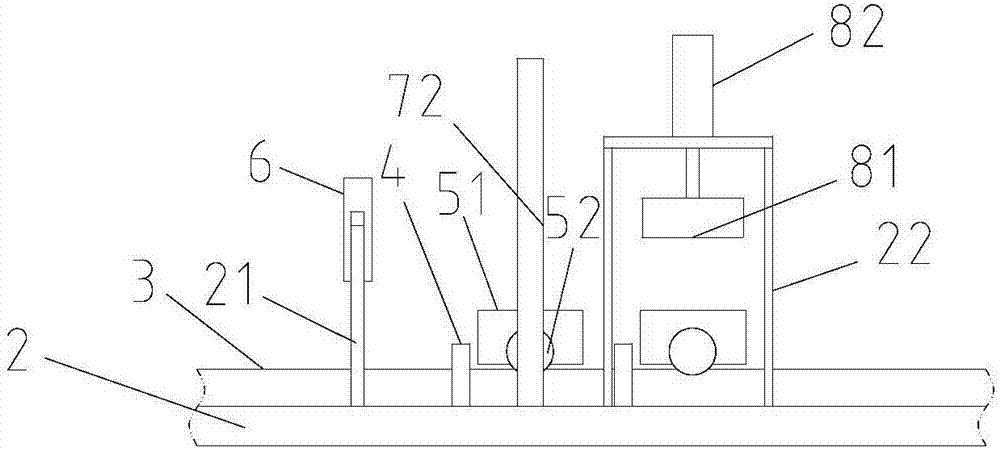

[0029] Such as figure 1 , 2 As shown, an automatic lead sealing device for smart meters, it includes:

[0030] A vibrating tray 1, the discharge port of the vibrating tray 1 is connected with a conveying trough 11 for conveying lead seals;

[0031] Conveying platform 2, on which a conveyor belt 3 for transmitting smart meters is set;

[0032] An upper seal device for moving the seal from the end of the delivery tank 11 to the seal hole of the smart meter;

[0033] A lead sealing device for firmly pressing the lead seal on the smart meter, the upper lead seal device and the lead seal device are sequentially arranged on the transfer platform 2 along the conveying direction of the smart meter;

[0034] The stopping device used to limit the movement of the smart meter is provided with a stopping device at the positions corresponding to the upper seal device and the pressure seal device of the transfer table 2;

[0035] The optical fiber sensor 4 used to detect the smart meter ...

Embodiment 2

[0044]A working method for an automatic lead sealing device for a smart meter as described in Embodiment 1, the method includes the following steps:

[0045] (1) The vibrating tray 1 transports the lead seal to the end of the delivery trough 11 through the delivery trough 11;

[0046] (2) After the optical fiber sensor 4 corresponding to the stopping device of the upper lead sealing device detects the smart meter, the corresponding stopping device of the upper lead sealing device acts, thereby limiting the movement of the smart meter;

[0047] (3) The upper lead seal device moves, put the lead seal at the end of the conveying tank in step (1) into the lead seal hole of the smart meter in step (2), and then reset the stopper corresponding to the upper lead seal device , the smart meter continues to be transmitted by the conveyor belt 3;

[0048] (4) After the optical fiber sensor 4 corresponding to the stop device of the lead sealing device detects the smart meter, the stop de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com