Adhesive sticker compound machine

A compound machine and sticker technology, applied in the field of machinery, can solve the problems of severe tool wear, inability to deal with air bubbles, and inability to deal with dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

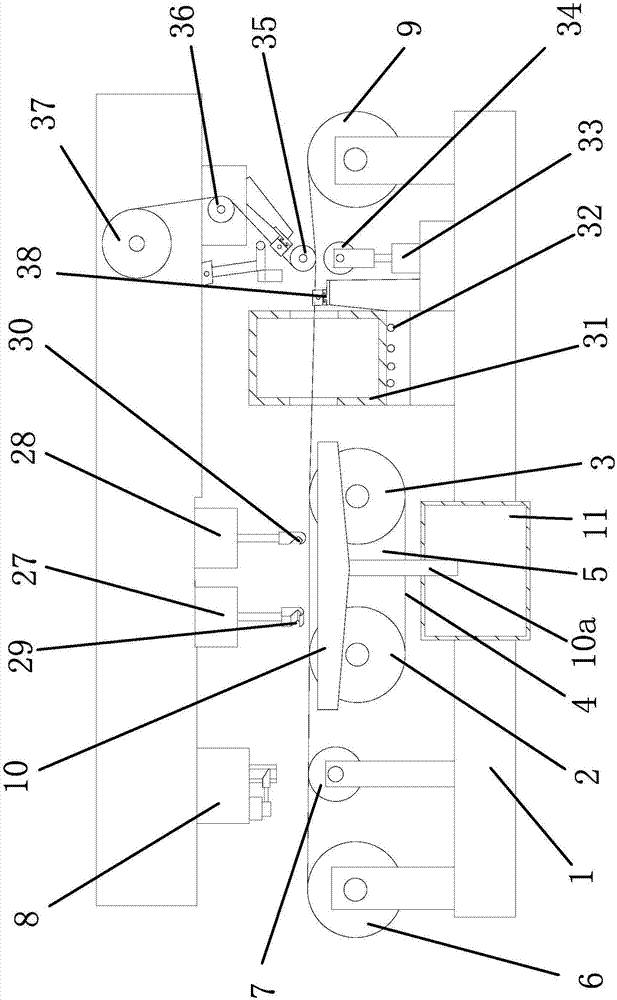

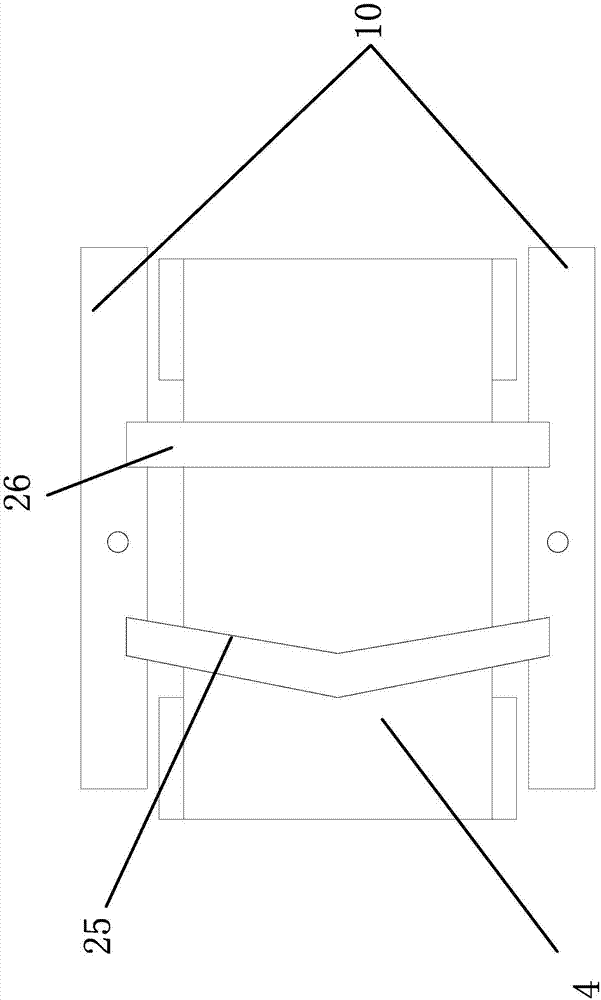

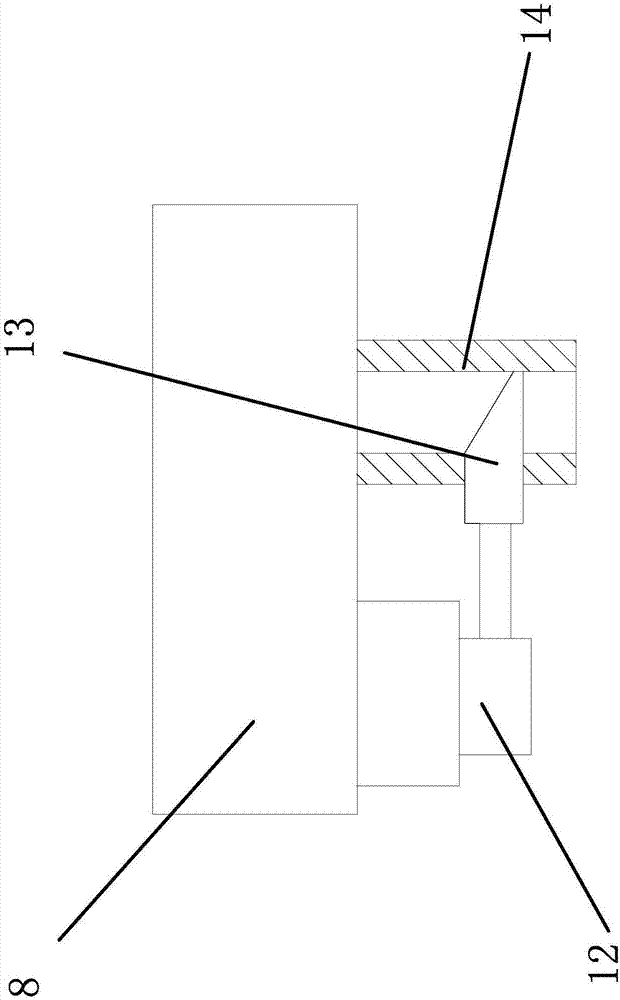

[0047] Such as Figures 1 to 6 As shown, the self-adhesive sticker compound machine includes a frame 1, and the frame 1 is provided with a roller one 2 and a roller two 3 in a circumferentially rotating and axially fixed manner, and a roller one 2 and a roller two 3 Parallel to each other, roller 1 2 and roller 2 3 are covered with an annular conveyor belt, and between roller 1 2 and roller 2 3 there is a pad, the pad is located in the conveyor belt, and the pad is fixed on the machine. On the frame 1; the side of the roller one 2 and the side away from the roller two 3 are provided with an axially rotating unwinding drum one, and an auxiliary roller one 2 is arranged between the roller one 2 and the unwinding drum one, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com