Bubble isolating device for extrusion machine ink groove

A technology of isolation device and ink tank, which is used in general parts of printing machinery, printing presses, printing and other directions, can solve the problems of printing finished designs, large ink volume and scratches at the outlet of the ink delivery tube, and ensure the extrusion and duplication of finished products. efficiency, achieve effective isolation, compact structure and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] For ease of understanding, the specific structure and working method of the present invention are described as follows in conjunction with the accompanying drawings:

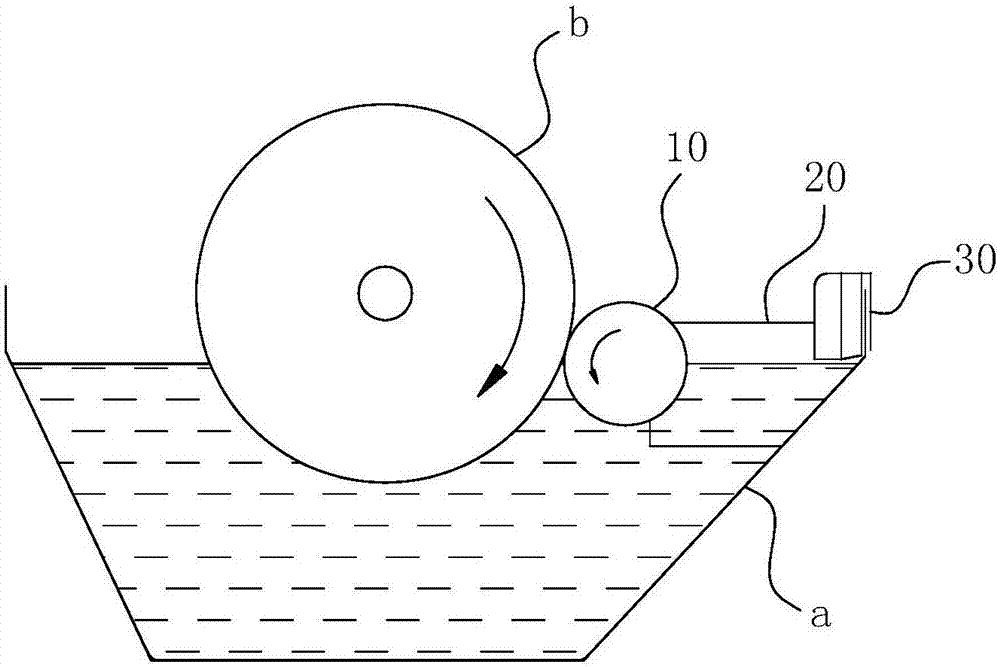

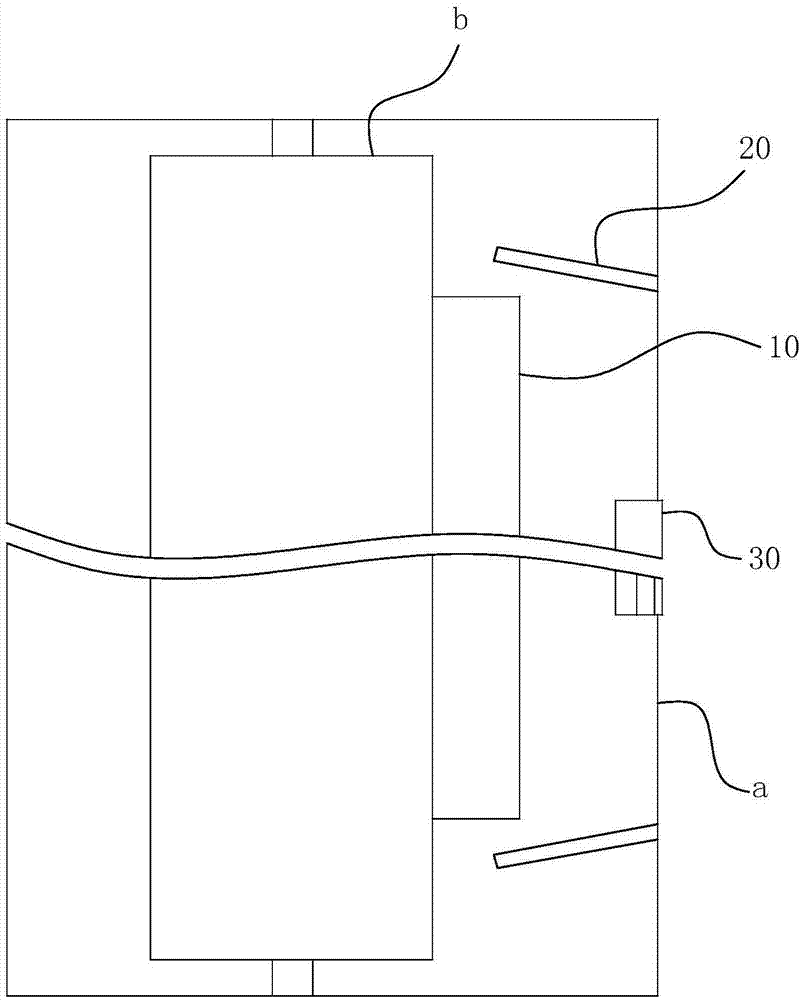

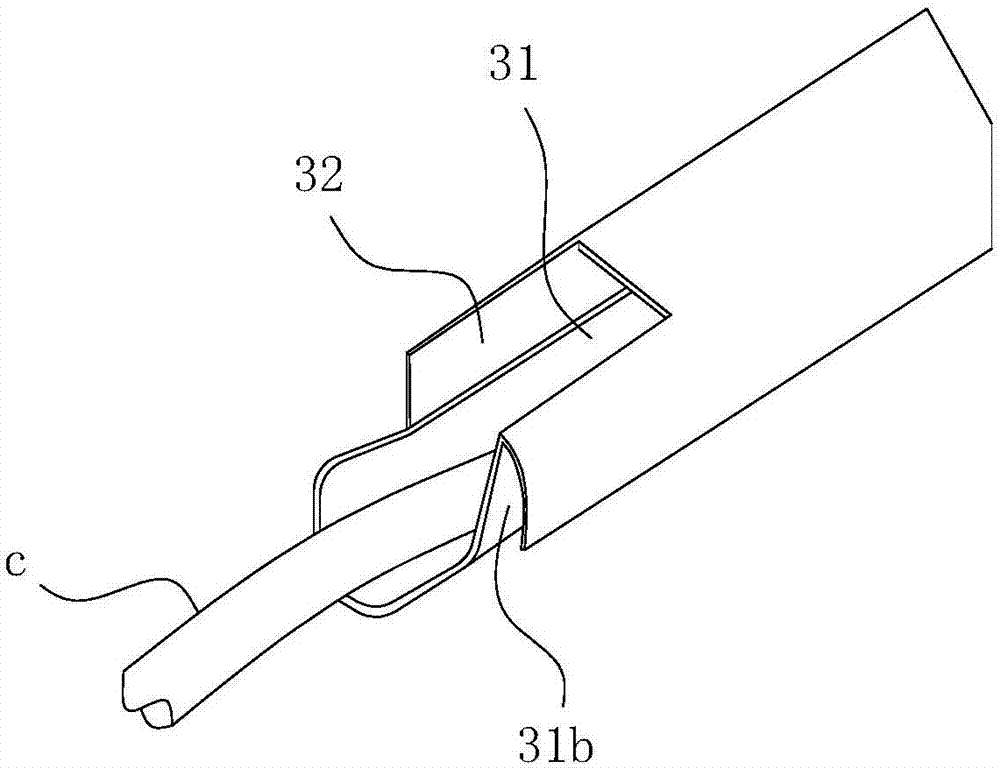

[0029] When the inking roller b works, it is actually as figure 1 Only part of the roller is shown below the ink level. When the inking roller b rotates and inks, first figure 1 The right side of the roller surface enters the ink, and this entry side is the ink inlet side of the ink roller b; similarly, when the ink roller b continues to rotate, the roller surface below the ink liquid surface will continue to move and bring out the ink , and then cooperate with the embossing roller at the main machine of the extruder to realize the ink coating function on the film die surface. And the tank wall of the side of the ink tank a that is relatively close to the dancer roller 10 is actually the tank wall where the ink separation assembly 30 is placed, that is, figure 1 The right tank wall shown is the side wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com