Platform gap junction device

A technology of gap connection and platform, applied in the direction of stations, transportation and packaging, railway car body parts, etc., can solve problems such as hidden safety hazards, achieve the effect of ensuring safe passage and enhancing safety protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

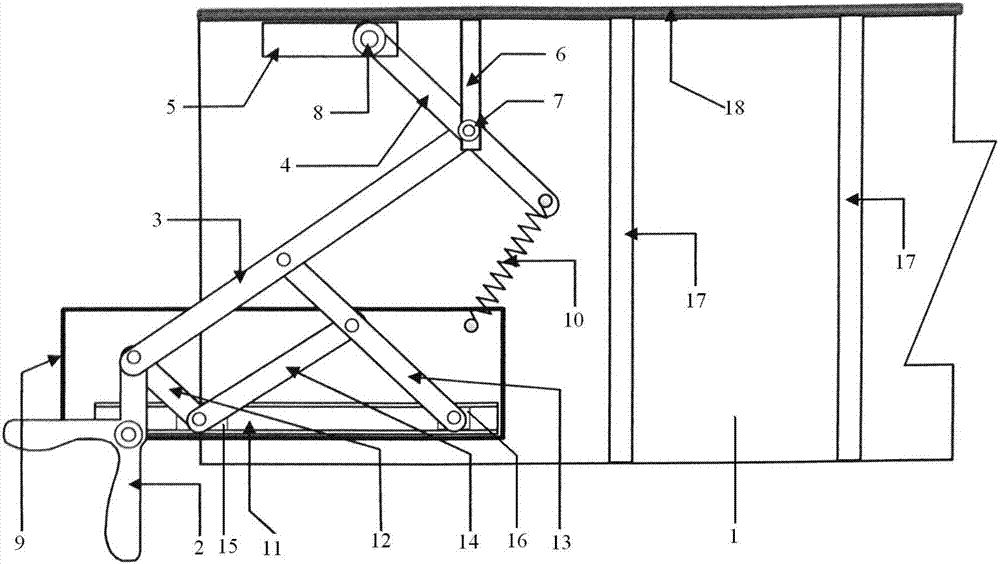

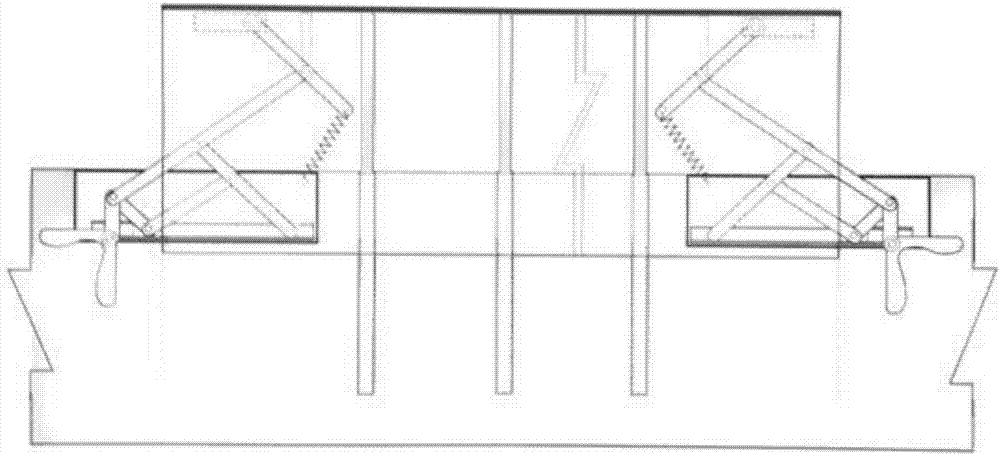

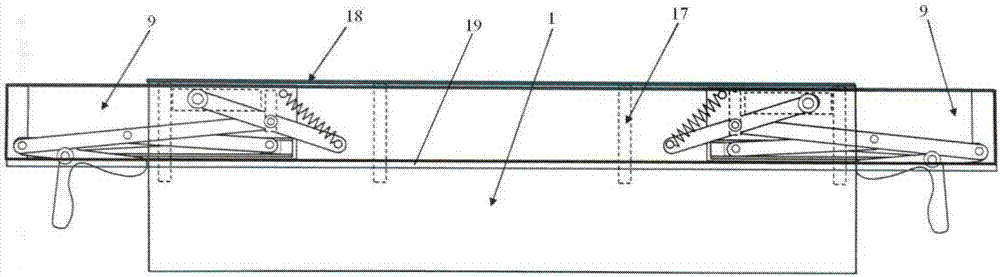

[0023] Platform gap connection devices, such as Figure 1-Figure 3 As shown, it includes a telescopic bridge plate 1 that can cover the gap between the train and the platform through telescopic movement, and also includes a transmission mechanism for driving the rod 2 and connecting with the driving rod 2 to realize the expansion and contraction of the telescopic bridge plate 1. The transmission mechanism is located on the telescopic bridge. Below the plate 1, and on both sides of the telescopic bridge plate 1, there are transmission mechanisms. The telescopic bridge plate 1 is a striped non-slip bridge plate made of alloy, that is, the plate surface of the telescopic bridge plate is provided with anti-skid stripes, and the thickness of the telescopic bridge plate 1 is 3 mm. The telescopic bridge plate 1 made of alloy has low cost, high strength High, no rust, easy to promote the advantages.

[0024] The transmission mechanism includes the main connecting rod 3 hinged with th...

Embodiment 2

[0030] The same as embodiment 1, the difference is that the telescopic bridge 1 is driven by electric power, specifically, a motor is installed on the edge of the platform, and the motor drives the driving rod 2 to rotate, so that the driving rod 2 drives the transmission mechanism to run, so that the telescopic bridge 1 extend or retract.

Embodiment 3

[0032] Same as embodiment 1 or 2, the difference is that the thickness of the telescopic bridge plate 1 is 6mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com