Construction method of long-span steel truss suspension structure

A technology of suspension structure and construction method, which is applied in building structure, processing of building materials, construction, etc., can solve problems such as cracking of concrete floor slabs, poor transverse structural strength and stability, and achieve good stress stability and easy solution Effects of Cracking, Strong Structural Strength and Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0040] As another preferred embodiment of the present invention, assembling the steel frame beams 32 and supporting columns 23 layer by layer from bottom to top includes:

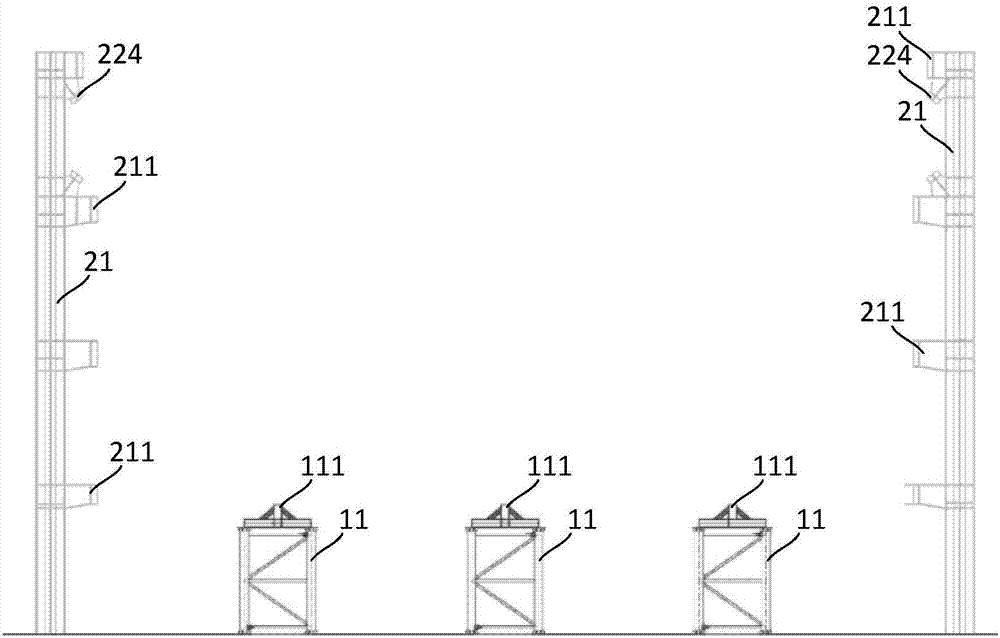

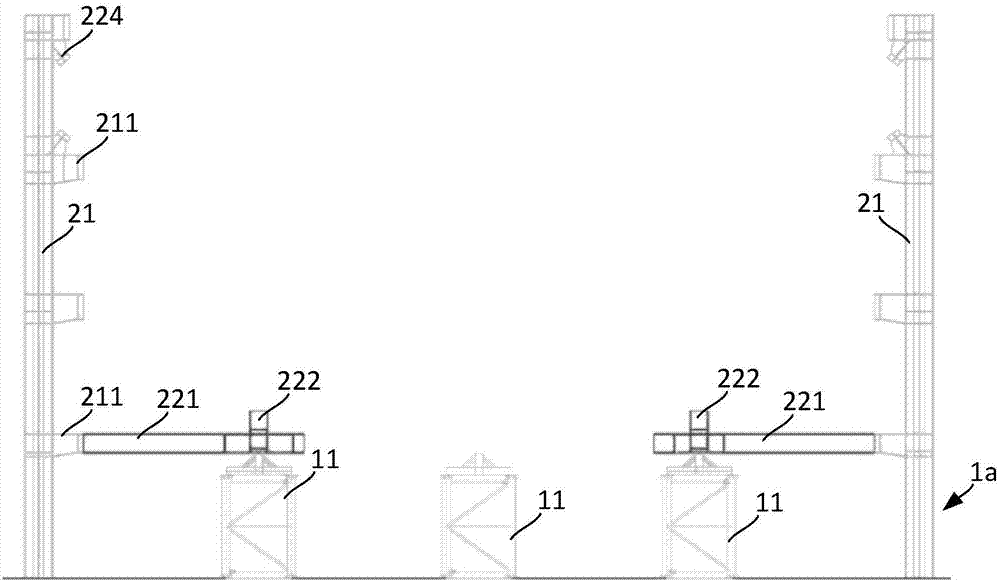

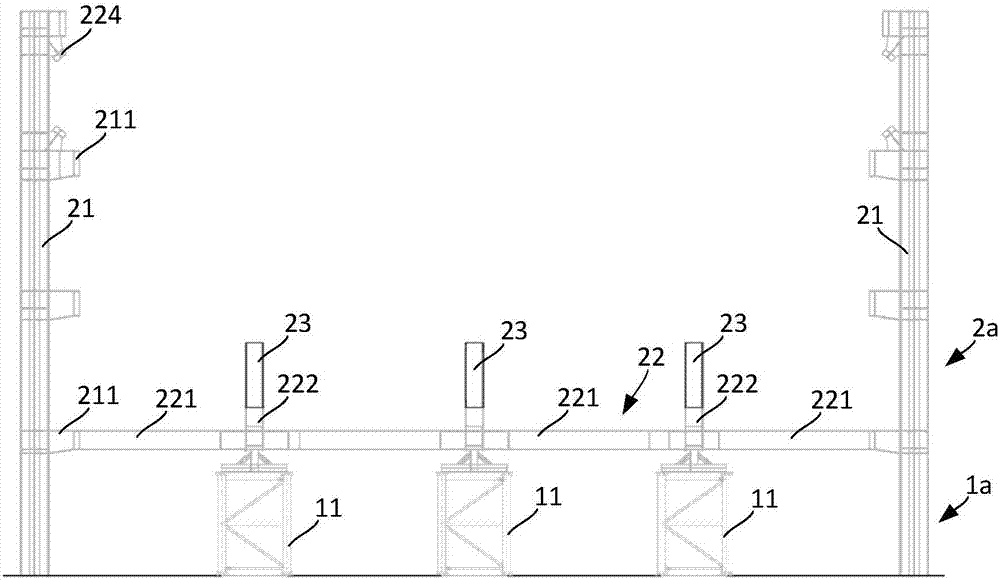

[0041] Such as figure 2 and image 3 As shown, the steel frame beam 22 of each layer is divided to form a plurality of steel beam units 221, and when assembling the steel frame beam 22 of each layer, the multiple steel beam units 221 are hoisted in place for butt joint assembly to form a steel frame beam twenty two. When assembling the steel frame beams 22 at the top of the first layer 1a of the structure, the steel beam units 221 located on both sides are hoisted first, and the steel beam units 221 are connected with the corresponding steel frame columns 21 and the support frame 11, that is, the steel beam units One end of the unit 221 is connected to the steel beam connection node 211 on the steel frame column 21, and the other end is placed and connected to the support node 111 supporting the tire fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com