A continuous pouring technology for double-trolley lining of reinforced concrete lining tunnel with single working face

A technology of reinforced concrete and lining trolley, which is applied in shaft lining, tunnel lining, tunnel and other directions, and can solve problems such as difficulty in guaranteeing construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

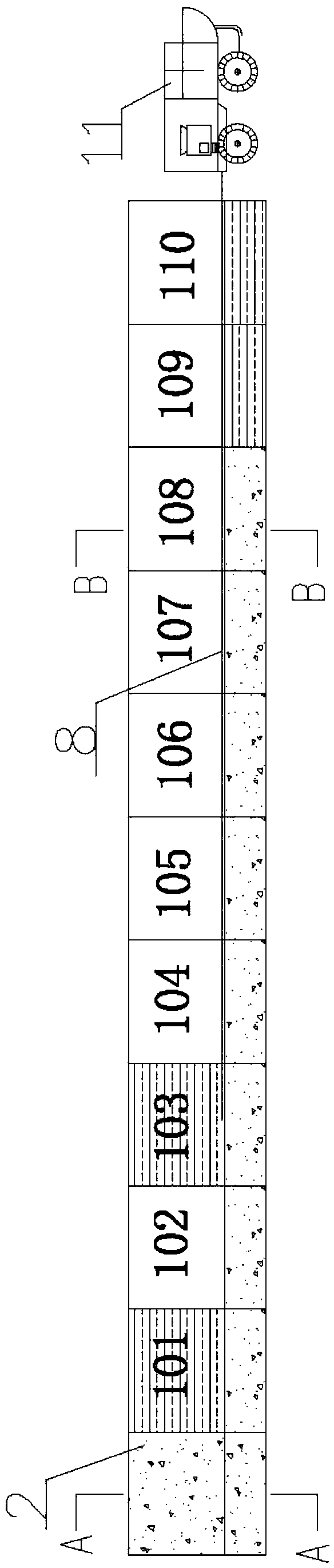

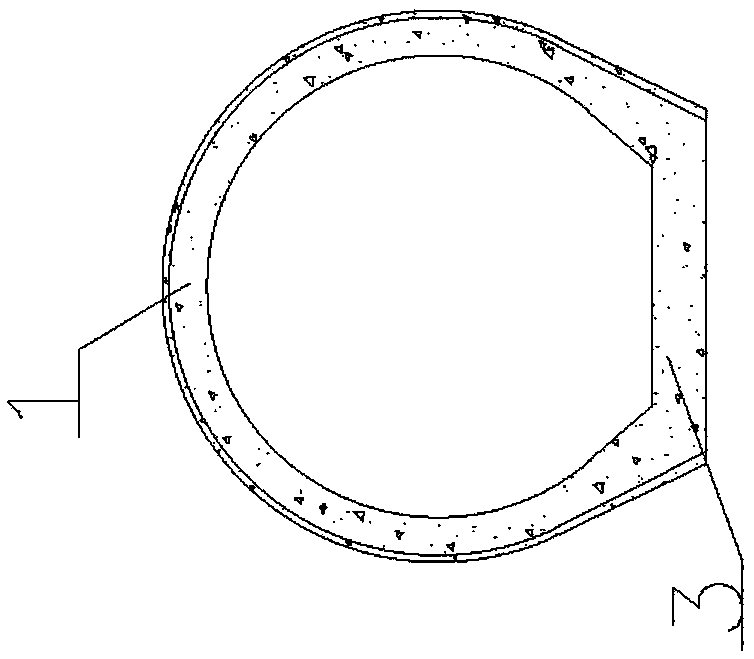

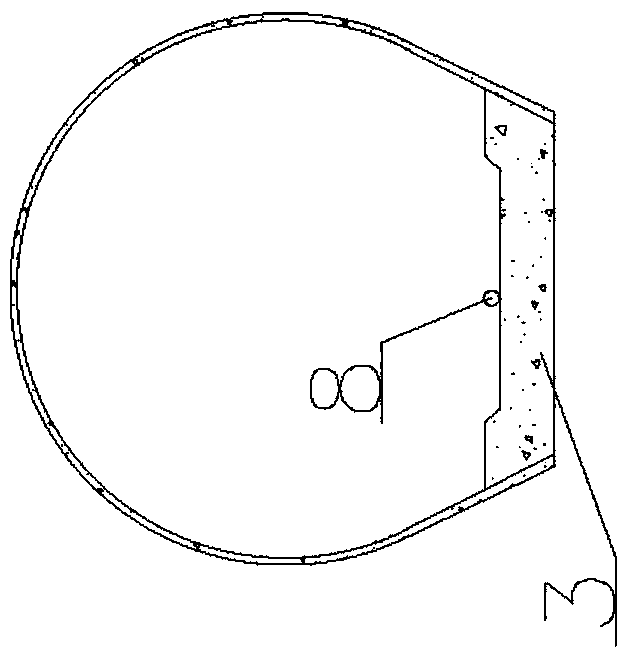

[0020] The double-trolley continuous pouring method for reinforced concrete lining tunnels provided by the present invention is equipped with two side arch lining trolleys and one pump truck 11 in the single working surface tunnel, and each side arch lining trolley A side arch maintenance trolley is arranged at the rear of the front arch lining trolley, and the side arch maintenance trolley of the front arch lining trolley is located between the front arch lining trolley and the rear crown lining trolley;

[0021] Before the continuous pouring construction of double-trolley lining with single working face, the binding of steel bars for the side arches of the first five warehouses starting from the side arch 2 of the lined section should be completed in advance, and the steel bars for the bottom plate of the eight warehouses starting from the side arch 2 of the lined section should be completed in advance. Ann and concrete pouring.

[0022] Then, starting from the third warehou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com