Conveyor system and method for painting armored vehicles

A conveying system and armored vehicle technology, which is applied in the field of conveying systems for armored vehicle painting, to achieve the effects of improving quality and product qualification rate, improving production efficiency, and reducing repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described in detail with reference to the accompanying drawings and examples.

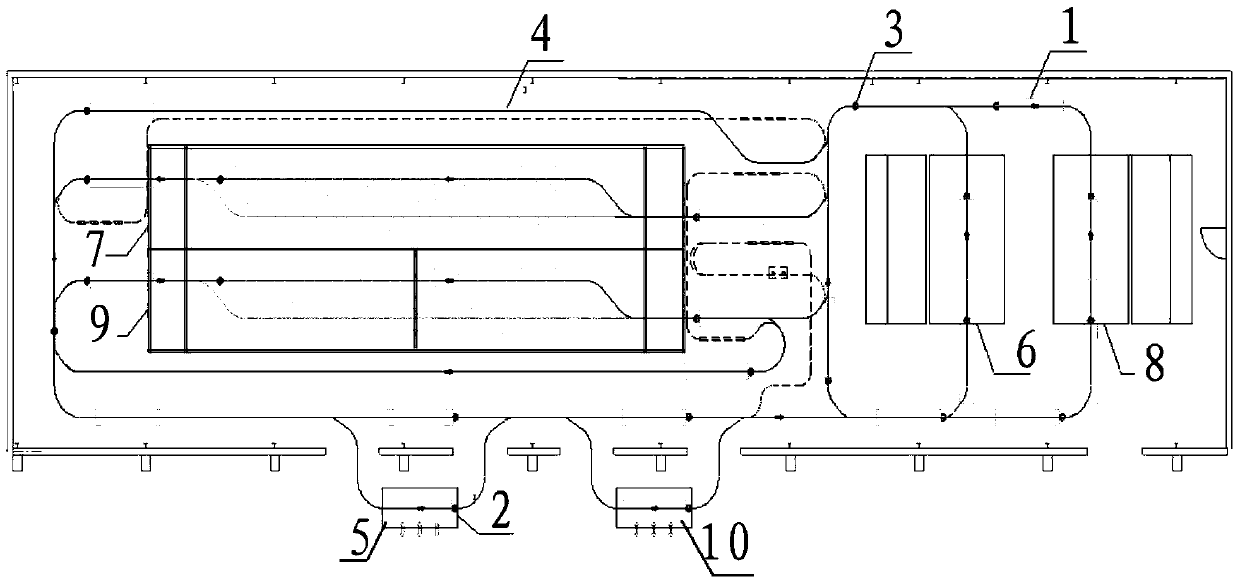

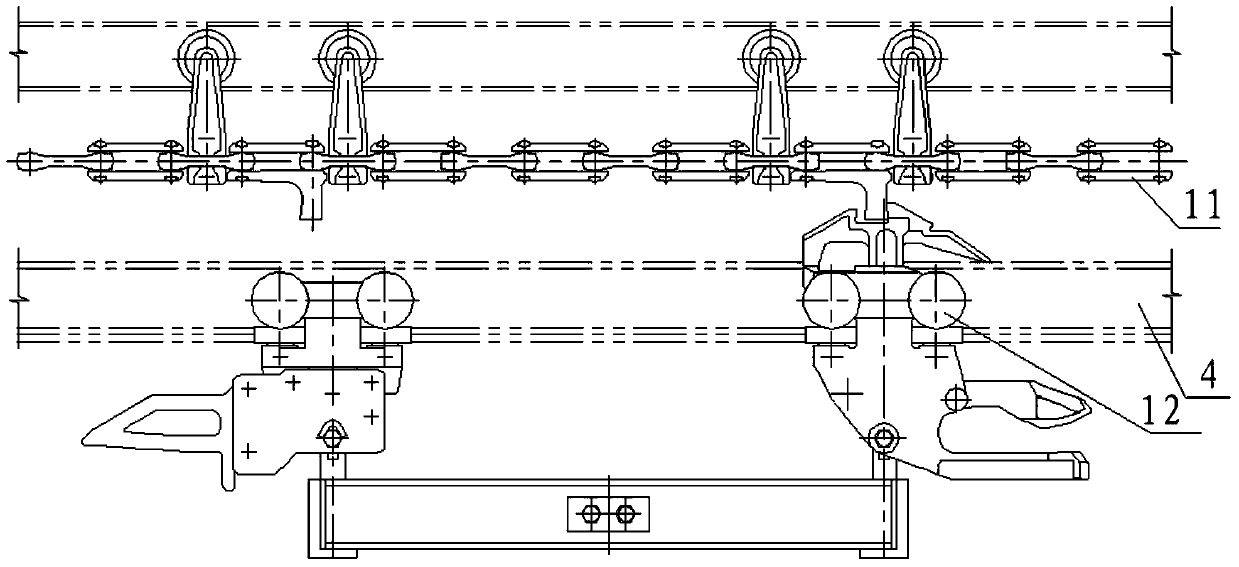

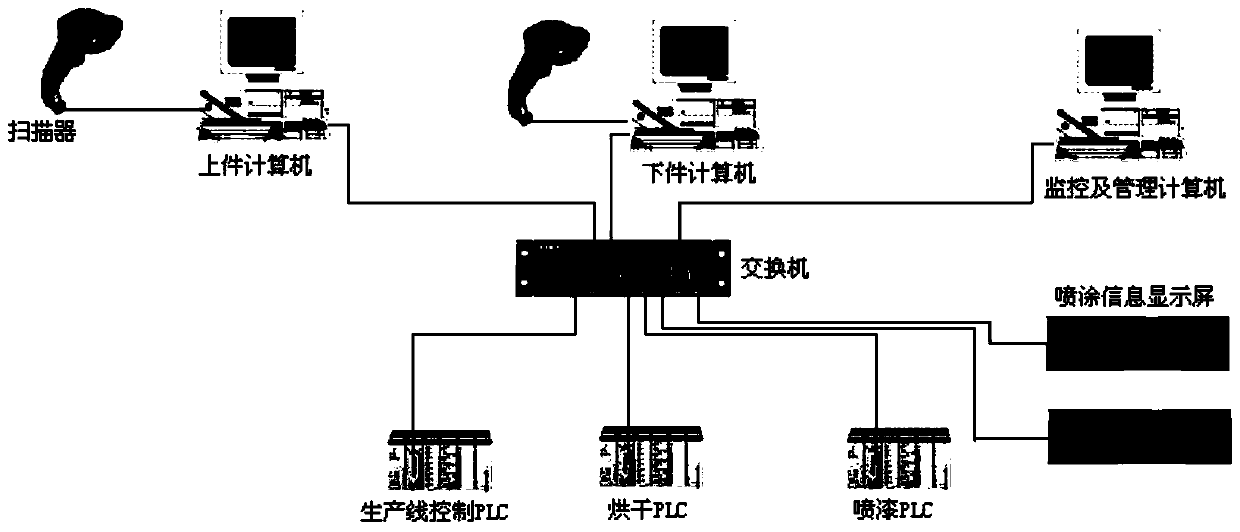

[0019] Such as figure 1 As shown, the present invention provides a conveying system for armored vehicle painting, including a process frame 1, a code scanning system, a lifting platform 2, a traction chain 11, a walking chain 12, a stopper 3, a track 4 and a spreader; the same process Workpieces with the same spraying process are hung on the frame. The lifting platform is set in the upper and lower work area. The craft frame is hung on the walking chain through the lifting platform. , the main road circulation of the track passes through the upper part area 5, the primer spraying room 6, the primer drying room 7, the top paint spraying room 8, the top paint drying room 9 and the lower part area 10, wherein, there are Turnout, the primer spraying room and the topcoat spraying room are connected in parallel, which can spray pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com