A tobacco storage system

A tobacco leaf, transportation and storage technology, applied in the direction of electrical program control, comprehensive factory control, etc., can solve the problems of unable to meet the whole process monitoring of tobacco leaves, unable to form an operation system, difficult equipment layout and construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

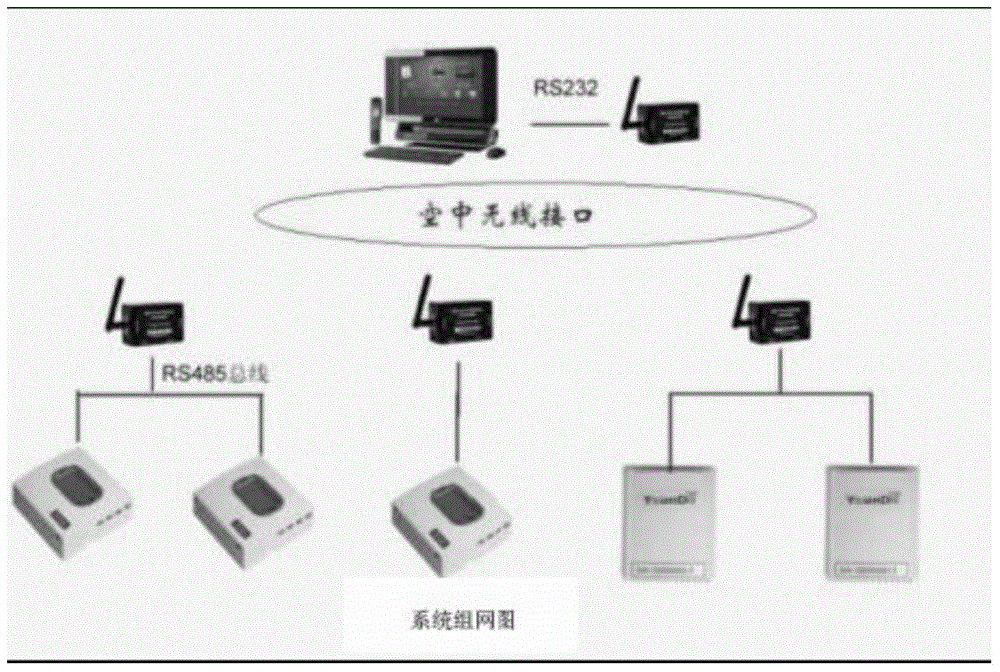

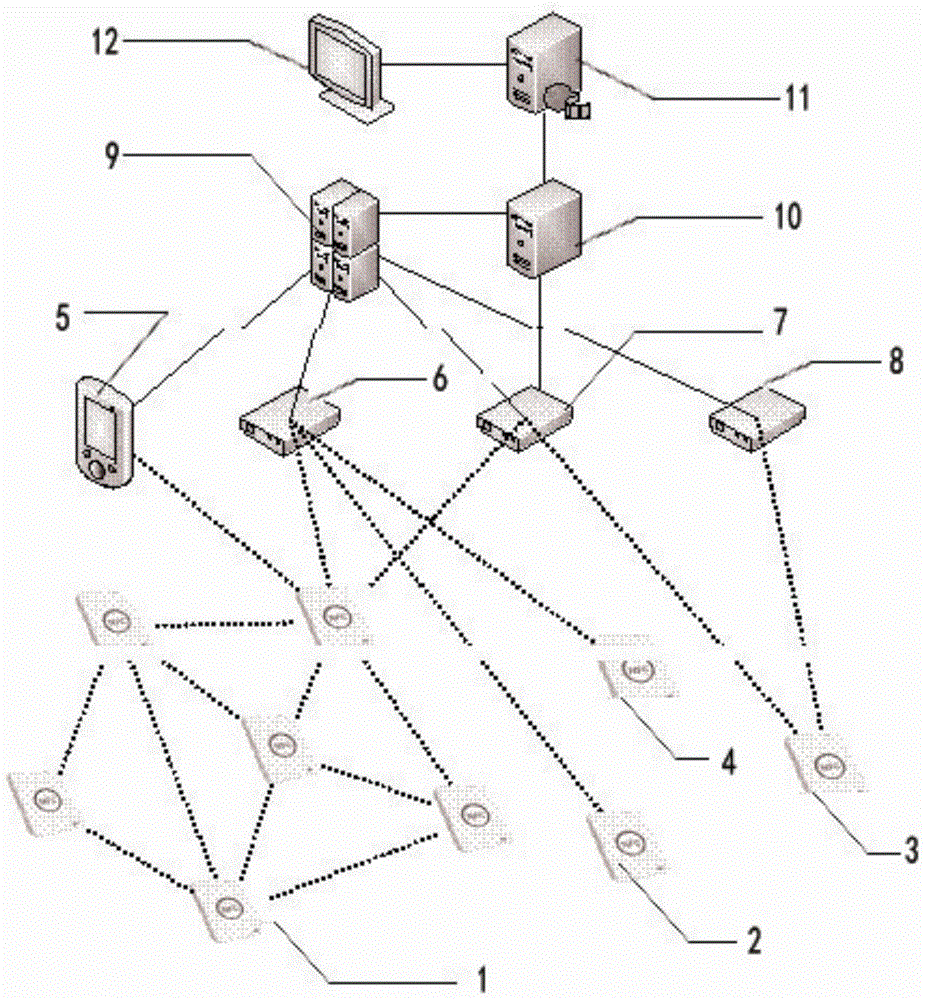

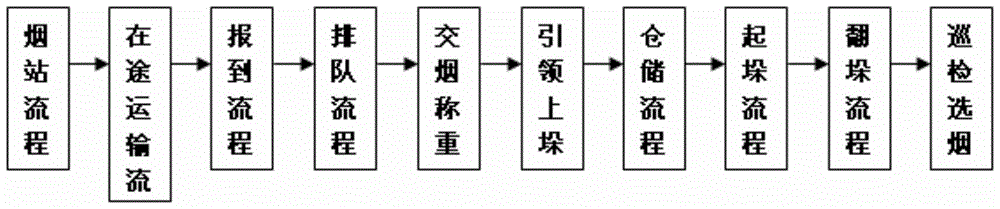

[0010] The tobacco leaf transportation and storage process is divided into image 3 Ten processes are shown.

[0011] attach now Figure 1-2 The application of the tobacco leaf transportation and storage system described in the present invention in ten processes will be further described.

[0012] 1 Smoke station process

[0013]

[0014] 2 In-transit transportation process

[0015]

[0016] 3Registration process

[0017]

[0018] 4 queuing process

[0019]

[0020] 5 Tobacco weighing process

[0021]

[0022] 6 Lead the stacking process

[0023]

[0024] 7 Warehousing process

[0025]

[0026] 8 stacking process

[0027]

[0028] 9 Turning process

[0029]

[0030] 10 Inspection and selection process

[0031]

[0032] The invention proposes a tobacco leaf transportation and storage system, which adopts a sensing card to integrate multiple sensors at the device layer to collect sensing information. The structure of the device sensing lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com