A three-stage erecting system

A technology of raising the vertical arm and branch circuit, which is applied to the control system of the gun, servo meter circuit, servo motor assembly, etc., can solve the problems of low control accuracy, easy to exceed the valgus point of the vertical arm, and poor stability, and achieve Reduce system energy consumption, improve rapid response capability and survivability, and reduce impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

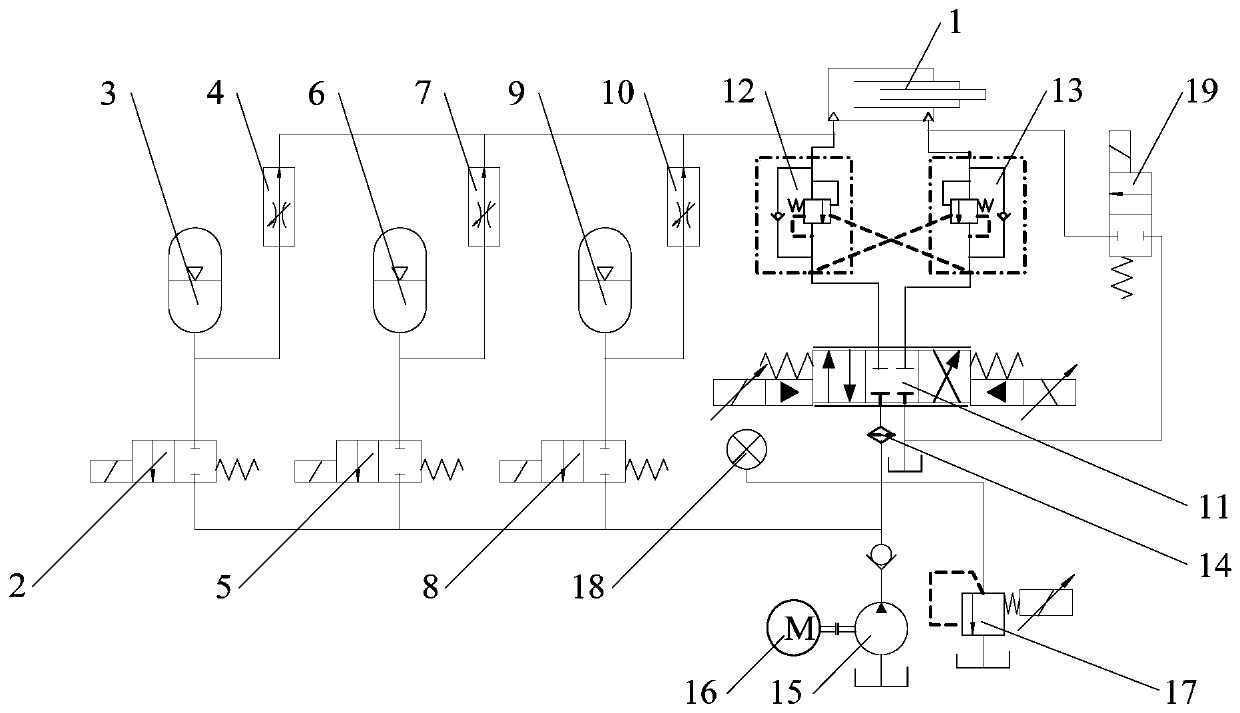

[0029] This embodiment provides a three-stage erecting system, such as figure 1As shown, it includes the oil supply unit, the three-stage hydraulic cylinder 1, the main power branch and three auxiliary power branches connected in parallel; Road and one of the auxiliary power branches are connected with the liquid outlet of the oil supply unit; the oil return circuit of the three-stage hydraulic cylinder 1 is connected with the external oil tank; the three auxiliary power branches can be divided into a high-pressure auxiliary power branch and a medium-pressure auxiliary power branch. Correspondingly, the three-stage hydraulic cylinder 1 can also be divided into high-pressure hydraulic cylinder, medium-pressure hydraulic cylinder and low-pressure hydraulic cylinder; the high-pressure auxiliary power branch is connected with the high-pressure hydraulic cylinder, and the medium-pressure auxiliary power branch The branch circuit communicates with the medium-pressure hydraulic cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com