Cable detection device

A detection device and cable technology, applied in the field of cables, can solve the problems of no pictures and inability to perform manual judgment, and achieve the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

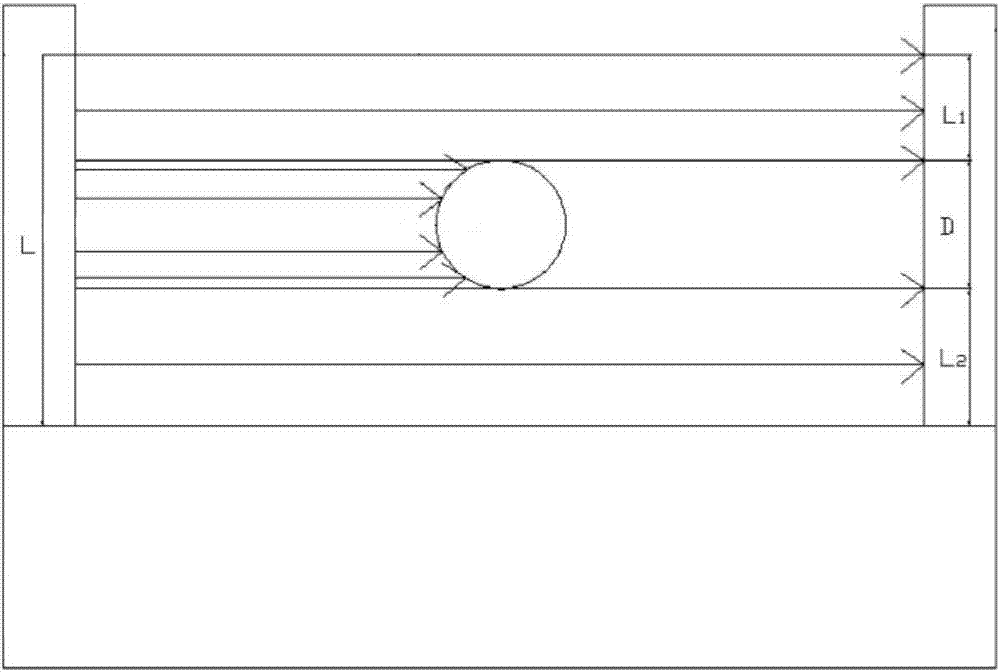

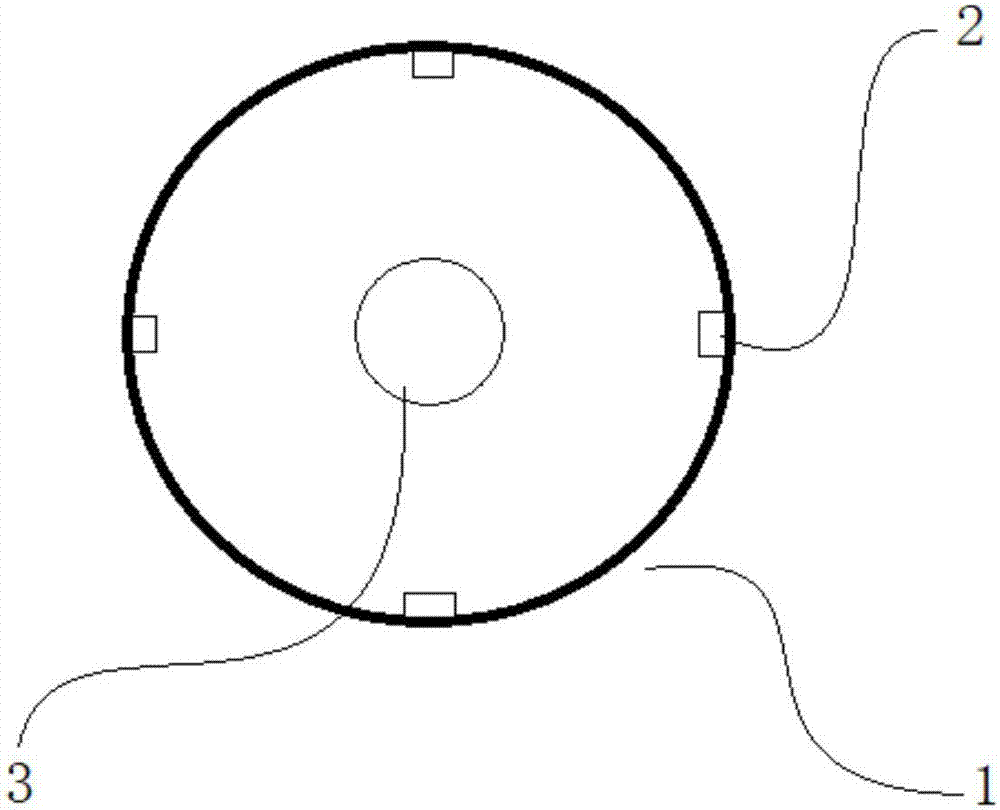

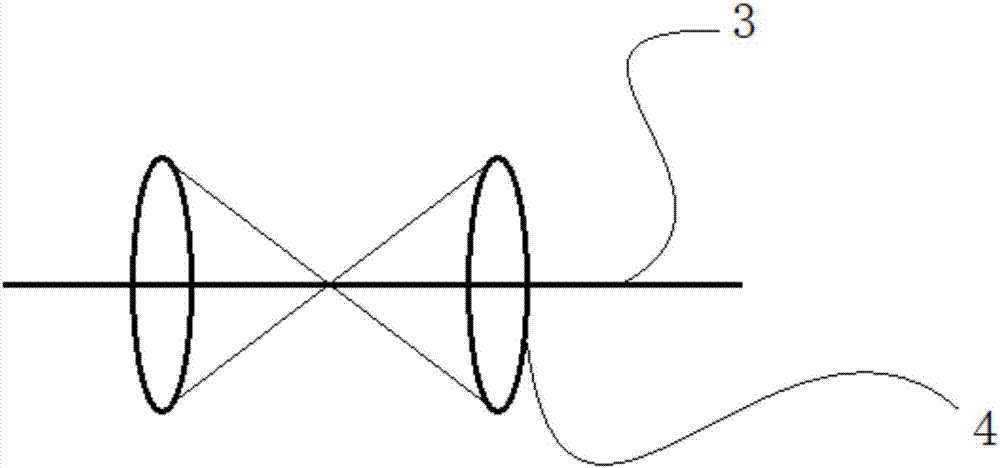

[0023] A cable detection device, comprising a first winding device, a second winding device and a detection channel 1 formed between the first winding device and the second winding device; one end of the cable 3 to be tested is connected to the first winding device, and the other One end is connected to the second winding device; a detection unit is arranged on the inner wall of the detection channel. The detection unit includes a first image acquisition unit and an illumination unit, the illumination unit illuminates the location to be detected of the cable to be tested, and the first image acquisition unit is used to acquire an image of the location to be tested of the cable to be tested.

[0024] Preferably, this embodiment also includes a marking machine, the marking machine is arranged in the detection channel and is located behind the detection unit. When the dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com