Seasoning for lamb chops and preparation method thereof

A production method and seasoning technology, which is applied in the field of seasoning, can solve the problems of seasoning without lamb chops, etc., and achieve the effect of short shelf life and suppressing quality changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

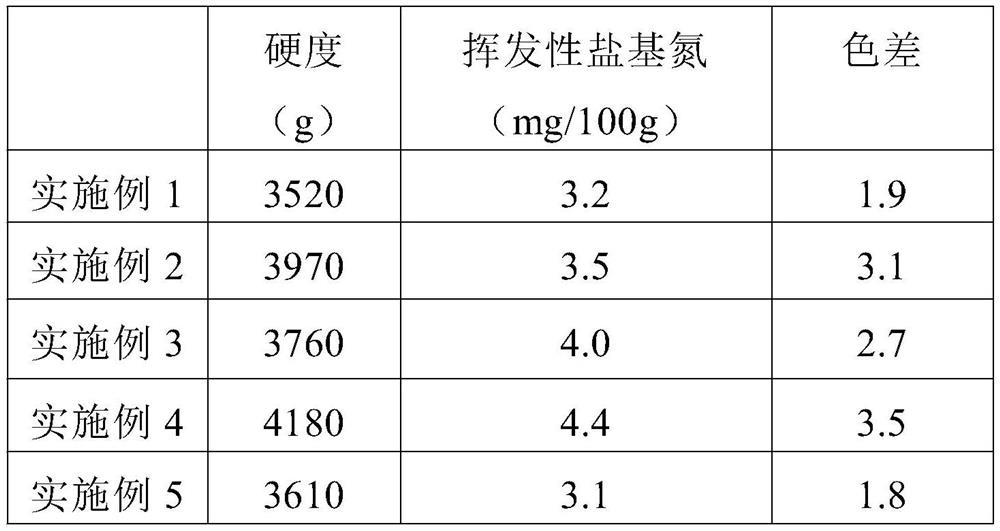

Examples

Embodiment 1

[0046] The preparation method of seasoning for lamb chops comprises the following steps:

[0047] S1: Grind Zanthoxylum bungeanum and pass through a 30-mesh sieve to obtain Zanthoxylum bungeanum powder; mix Zanthoxylum bungeanum powder with ethanol with a mass fraction of 75% (that is, an aqueous solution of ethanol, wherein the mass fraction of ethanol is 75%) at a solid-to-liquid mass ratio of 1:10 Uniform, under the condition of ultrasonic power 300W, ultrasonic frequency 35kHz, carry out ultrasonic extraction at 65°C for 2.5 hours to obtain the extract; centrifuge the extract at 3000 rpm for 15 minutes, discard the precipitate, take the supernatant at temperature Carry out rotary evaporation at 50°C, vacuum degree of 0.08MPa, and rotating speed of 60 rpm to remove the solvent, and obtain Zanthoxylum bungeanum oleoresin;

[0048] S2: uniformly mix Zanthoxylum bungeanum oleoresin, maltodextrin, and cornstarch in a mass ratio of 1:8:1 to obtain adsorption type Zanthoxylum bun...

Embodiment 2

[0052] The preparation method of seasoning for lamb chops comprises the following steps:

[0053]S1: Grind Zanthoxylum bungeanum and pass through a 30-mesh sieve to obtain Zanthoxylum bungeanum powder; mix Zanthoxylum bungeanum powder with ethanol with a mass fraction of 75% (that is, an aqueous solution of ethanol, wherein the mass fraction of ethanol is 75%) at a solid-to-liquid mass ratio of 1:10 Evenly, under the condition of microwave power 300W, carry out microwave extraction at 65°C for 2.5 hours to obtain the extract; centrifuge the extract at a speed of 3000 rpm for 15 minutes, discard the precipitate, and take the supernatant at a temperature of 50°C. The vacuum degree is 0.08MPa, and the rotation speed is 60 rpm to carry out rotary evaporation to remove the solvent to obtain the pepper oleoresin;

[0054] S2: uniformly mix Zanthoxylum bungeanum oleoresin, maltodextrin, and cornstarch in a mass ratio of 1:8:1 to obtain adsorption type Zanthoxylum bungeanum oleoresin;...

Embodiment 3

[0058] The preparation method of seasoning for lamb chops comprises the following steps:

[0059] S1: Grind Zanthoxylum bungeanum and pass through a 30-mesh sieve to obtain Zanthoxylum bungeanum powder; mix Zanthoxylum bungeanum powder with ethanol with a mass fraction of 75% (that is, an aqueous solution of ethanol, wherein the mass fraction of ethanol is 75%) at a solid-to-liquid mass ratio of 1:10 Evenly, carry out Soxhlet extraction for 2.5 hours to obtain the extract; centrifuge the extract at a speed of 3000 rpm for 15 minutes, discard the precipitate, and take the supernatant at a temperature of 50 °C, a vacuum of 0.08 MPa, and a speed of 60 Carry out rotary evaporation to remove solvent under rev / min, obtain Zanthoxylum bungeanum oleoresin;

[0060] S2: uniformly mix Zanthoxylum bungeanum oleoresin, maltodextrin, and cornstarch in a mass ratio of 1:8:1 to obtain adsorption type Zanthoxylum bungeanum oleoresin;

[0061] S3: Weigh each raw material by weight: 50 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com