A kind of tensile test method of trapezoidal copper bar

A tensile test and tensile testing machine technology, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, measuring devices, etc., can solve problems such as troublesome operation and inaccurate test data, and achieve consistent force, Simple operation and accurate tensile test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

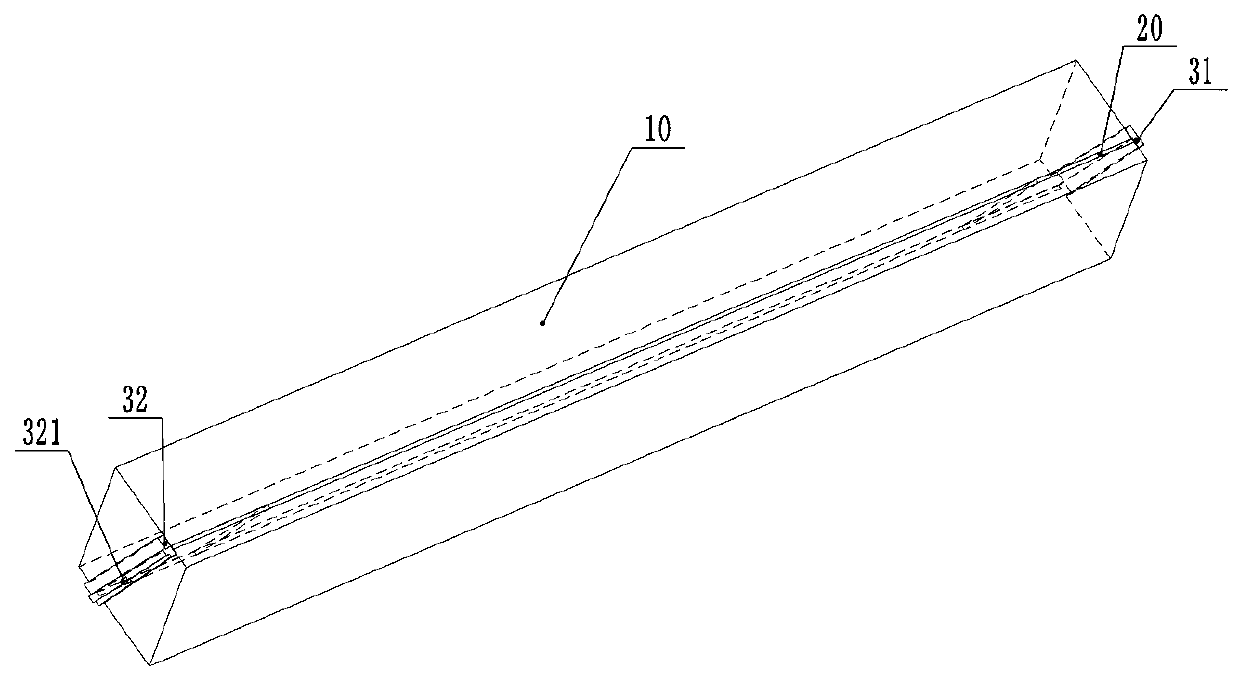

[0036] The difference between this embodiment and embodiment 1 is that in step (1), if figure 2 As shown, one end of the sandpaper 20 is provided with a first baffle 31, and the other end is provided with a second baffle 32; one end of the sandpaper 20 is fixed to one side of the first baffle 31, and the second baffle 32 is provided with a At the slit through which the other end of the sandpaper 20 passes, the side of the second baffle 32 away from the first baffle 31 is provided with a buckle 321 for fixing the sandpaper 20; when preparing a stretch pattern, adjust the width of the sandpaper 20 to a trapezoid The hypotenuses of the copper bars 10 are consistent, and then the buckles 321 are used to fasten the sandpaper 20, and the two trapezoidal copper bars 10 are placed on both sides of the sandpaper 20. The first baffle 31 and the second baffle 32 are respectively connected to the two trapezoid The two sides of the copper bar 10 are pasted together. The first baffle plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com