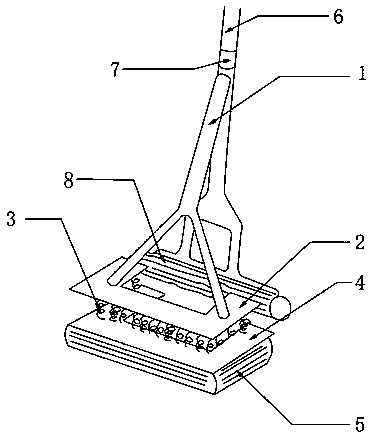

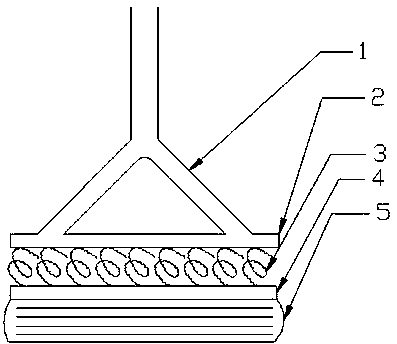

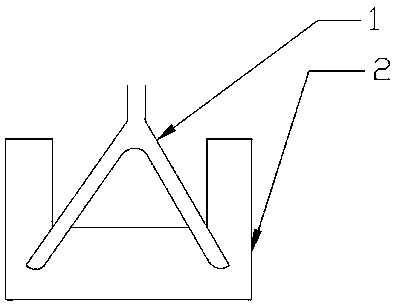

Dry-wet double-headed mop

A mop and double-head technology, applied in the field of mops, can solve the problems of secondary pollution, humidity, wet ground, etc., and achieve the effects of saving time, saving human resources, and benefiting human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] When preparing to mop the floor, take off the mop sub-bar 1, the upper clip 2, the lower clip 4, the spring part 3, and the water-absorbing part 5 through the bayonet 7, and only clean the wet part 8; complete the cleaning of the wet part 8 After cleaning, install the mop sub-pole 1, the upper clip 2, the lower clip 4, the spring part 3, and the water-absorbing part 5 on the mop main rod 6 through the bayonet 7 to mop the floor; When the mop main rod 6 is pulled backward, the spring part 3 is compressed through the upper clip 2, and its elastic force is transmitted to the half-packed water-absorbing part 5 through the lower clip 4 to generate positive pressure on the ground, so as to clean and mop the ground at the same time. for two purposes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com