Drying control method of cleaning machine system

A drying control and cleaning machine technology, applied in cleaning machines, robot cleaning machines, drying, etc., can solve the problems of easy dust, easy damage to fans, and easy mold of cleaning parts, so as to solve the problems of dampness and pollution of indoor environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

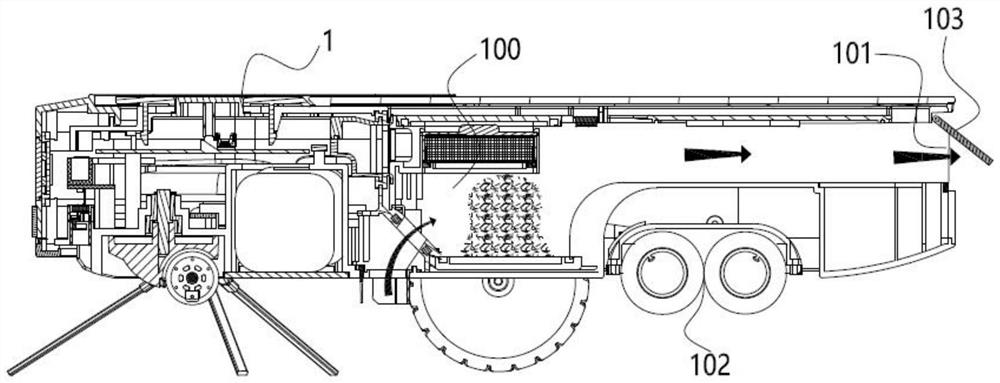

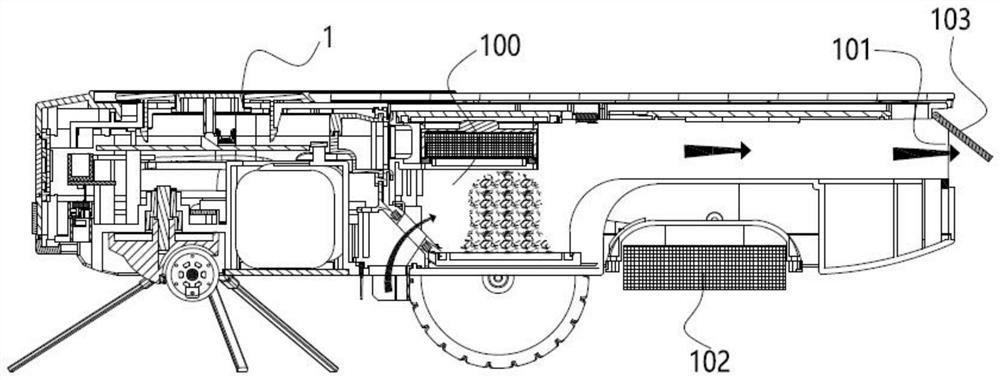

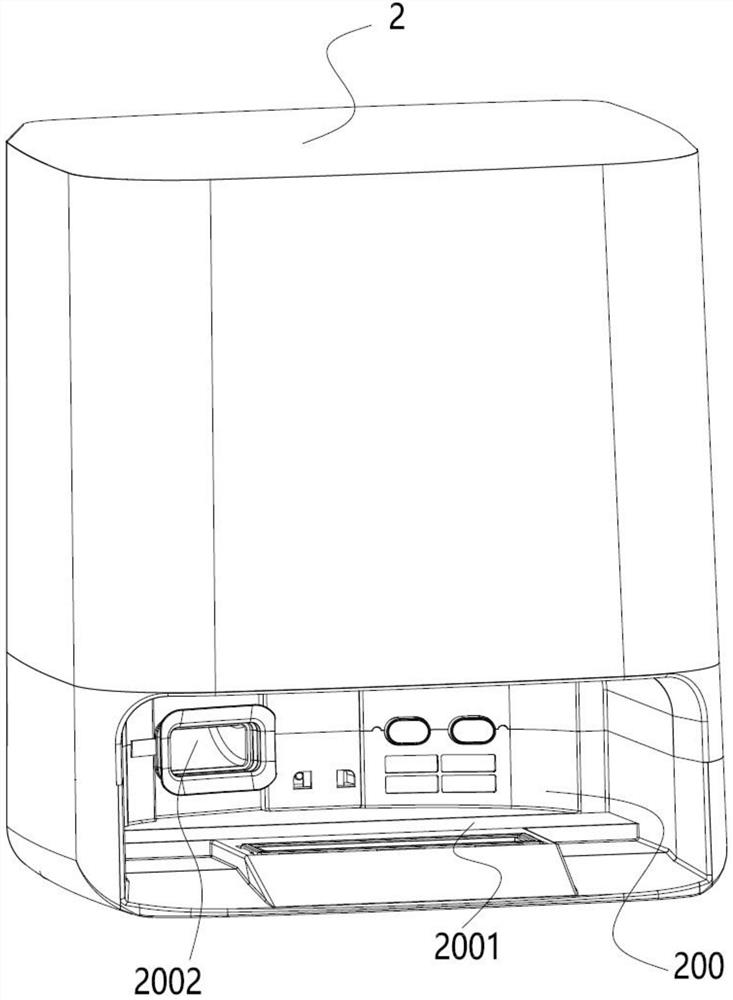

[0066] Embodiment: the drying control method of the cleaning machine system of the present invention, such as Figure 1 to Figure 16 As shown in the configuration, the cleaning machine 1 is used for mopping and vacuuming by walking on the ground, absorbing the garbage on the ground into the garbage cavity 100 in the cleaning machine 1 for collection, and using the cleaning parts 102 on the cleaning machine 1 mopping and cleaning the ground, and then realize the cleaning of the indoor floor; correspondingly, in order to realize the docking of the cleaning machine 1, the garbage collected by the cleaning machine 1 and the cleaning parts 102 are cleaned, and the cleaning parts are collected For the sewage formed after 102, the base station 2 is set up in this plan, and the cleaning machine 1 is maintained through the base station 2. The formed sewage is collected to realize the cooperative treatment of the dirt on the indoor floor by the cleaning machine 1 and the base station 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com