Assembly type temperature control metal windowsill structure

A prefabricated, window sill technology, used in windowsills/thresholds, building structures, windows/doors, etc., can solve problems such as insufficient thermal insulation and moisture removal performance, adverse effects on users' physical and mental health and human comfort, and prevent the surface area of windowsills. Effects of water, protection of graphene electric heating film, stability and firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

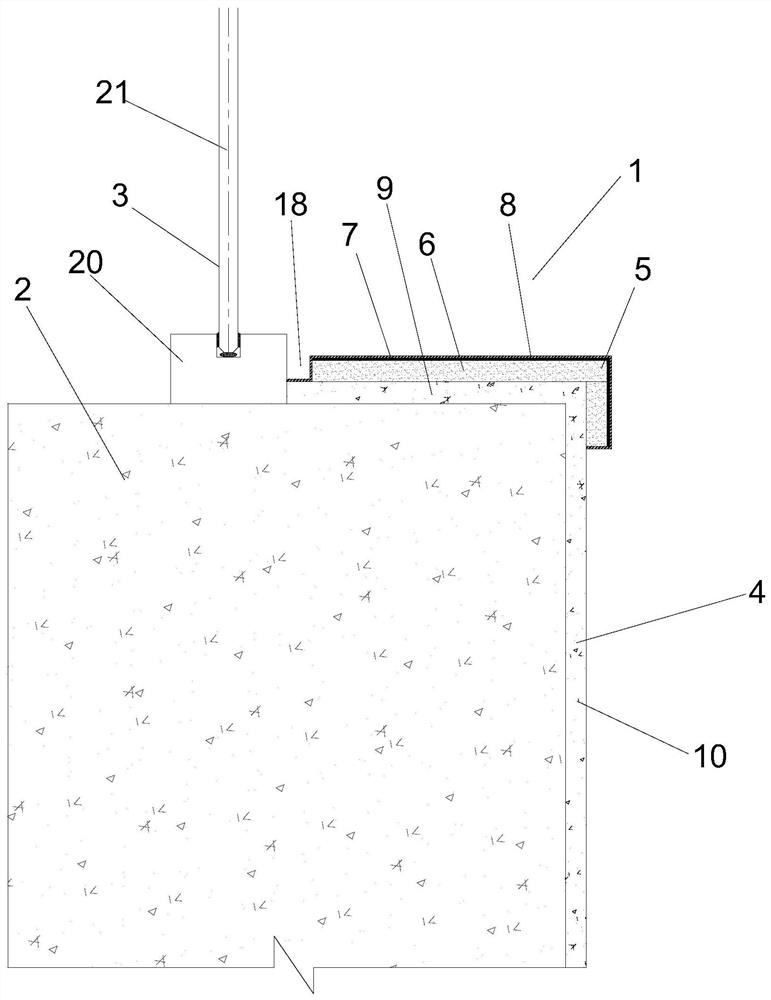

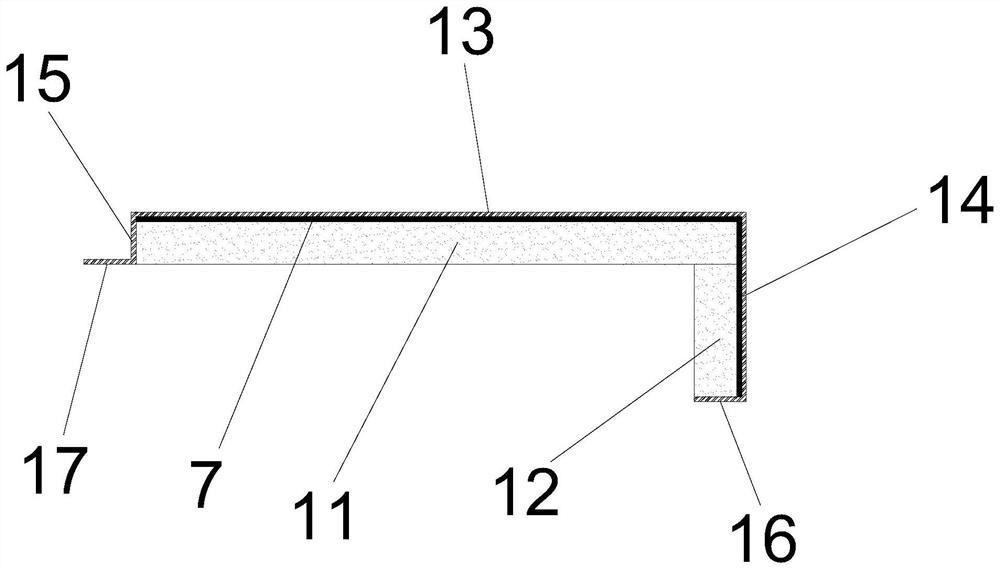

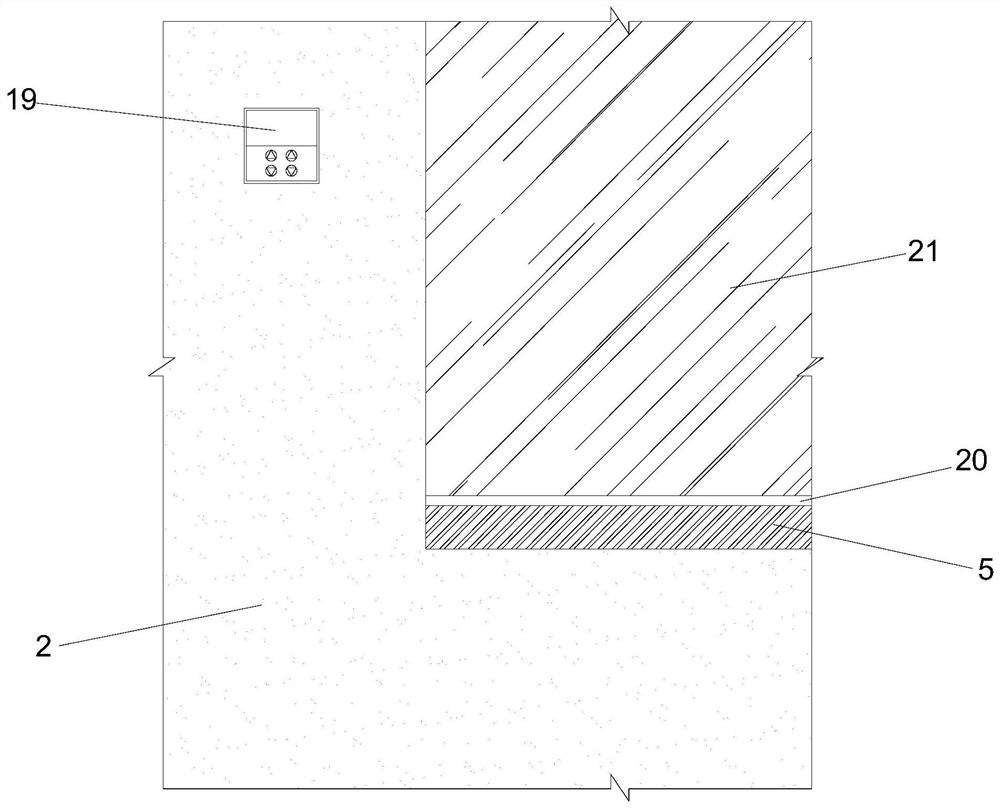

[0020] Such as figure 1 , 2 As shown, in the first embodiment of the fabricated temperature-controlled metal window sill structure of the present invention, the window sill structure 1 includes a glass window 3 fixed on the window sill building wall 2, fixed on the surface of the window sill building wall 2 and The window sill base layer 4 located inside the glass window 3, the heated metal window sill 5 fixed on the surface of the window sill base layer 4 and abutting against the inner surface of the glass window 3, the heated metal window sill 5 includes a fixed connection with the window sill base layer 4 The bottom plate 6 , the graphene electric heating film 7 laid on the top surface of the bottom plate 6 , and the metal plate 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com