Flat mop cleaning barrel

A flat mop and cleaning bucket technology, applied in cleaning equipment, cleaning machinery, carpet cleaning, etc., can solve problems such as poor cleaning effect of flat mop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

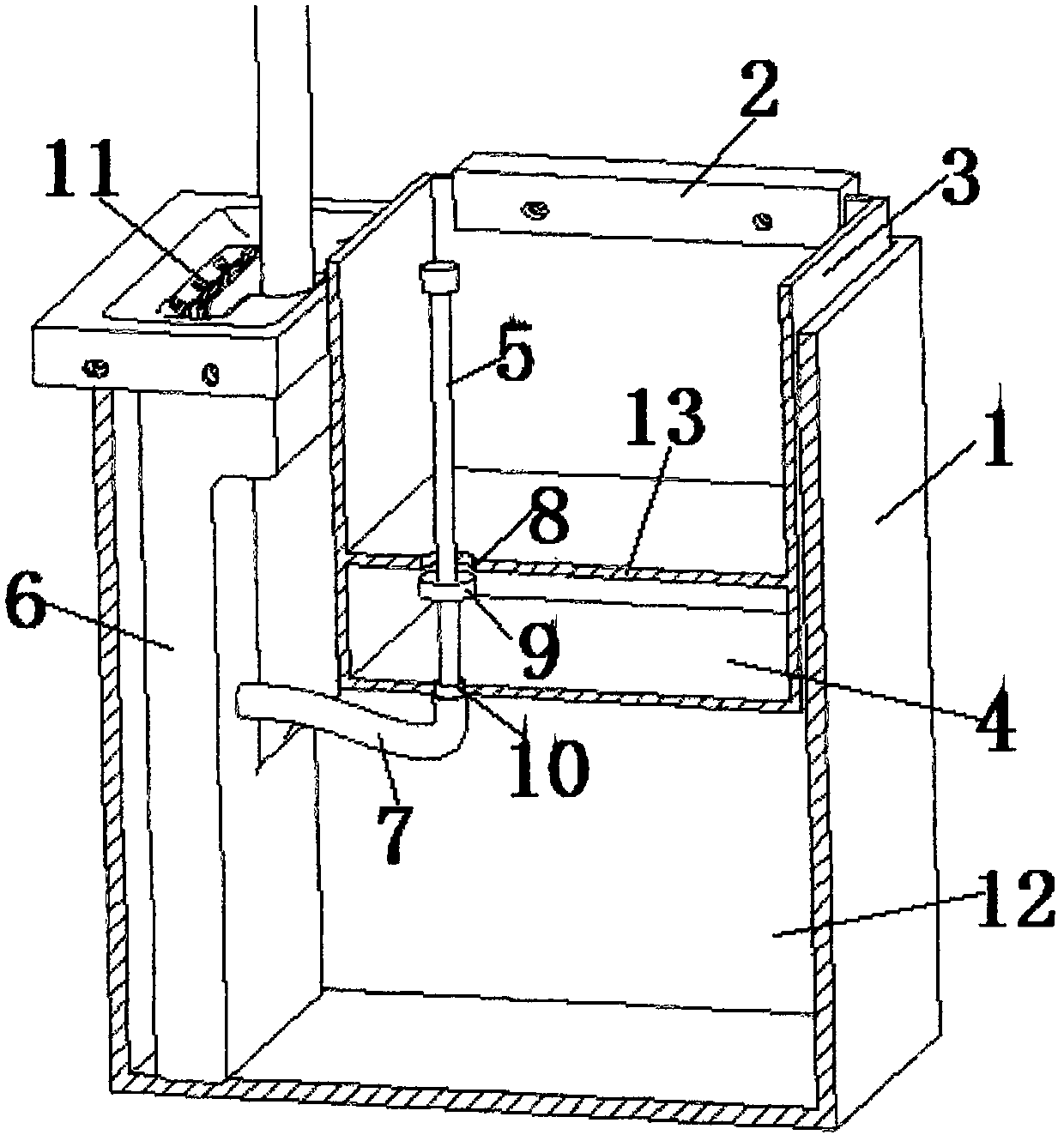

[0051] A flat mop cleaning bucket, comprising a bucket body 1, a cleaning area 6, a water purification area 2 and a sewage area 12, the cleaning area 6 and the water purification area 2 are connected through a water inlet pipe 7, and the bucket body 1 is provided with a supporting water purification area The support position of the water purification area in the district 2, the support position can be the support base positioned at the bottom of the barrel body 1 or the support structure arranged at the mouth of the barrel body or the inner wall to support the weight of the whole water purification area 2, this structure is very important to those skilled in the art It is conventional, as long as it can play a supporting role.

[0052] The cleaning area 6 is provided with a clean water inlet connected with the water inlet pipe 7 and a sewage outlet for discharging sewage in the cleaning area 6. The water purification area 2 is divided into a water purification area body 3 and a...

Embodiment 2

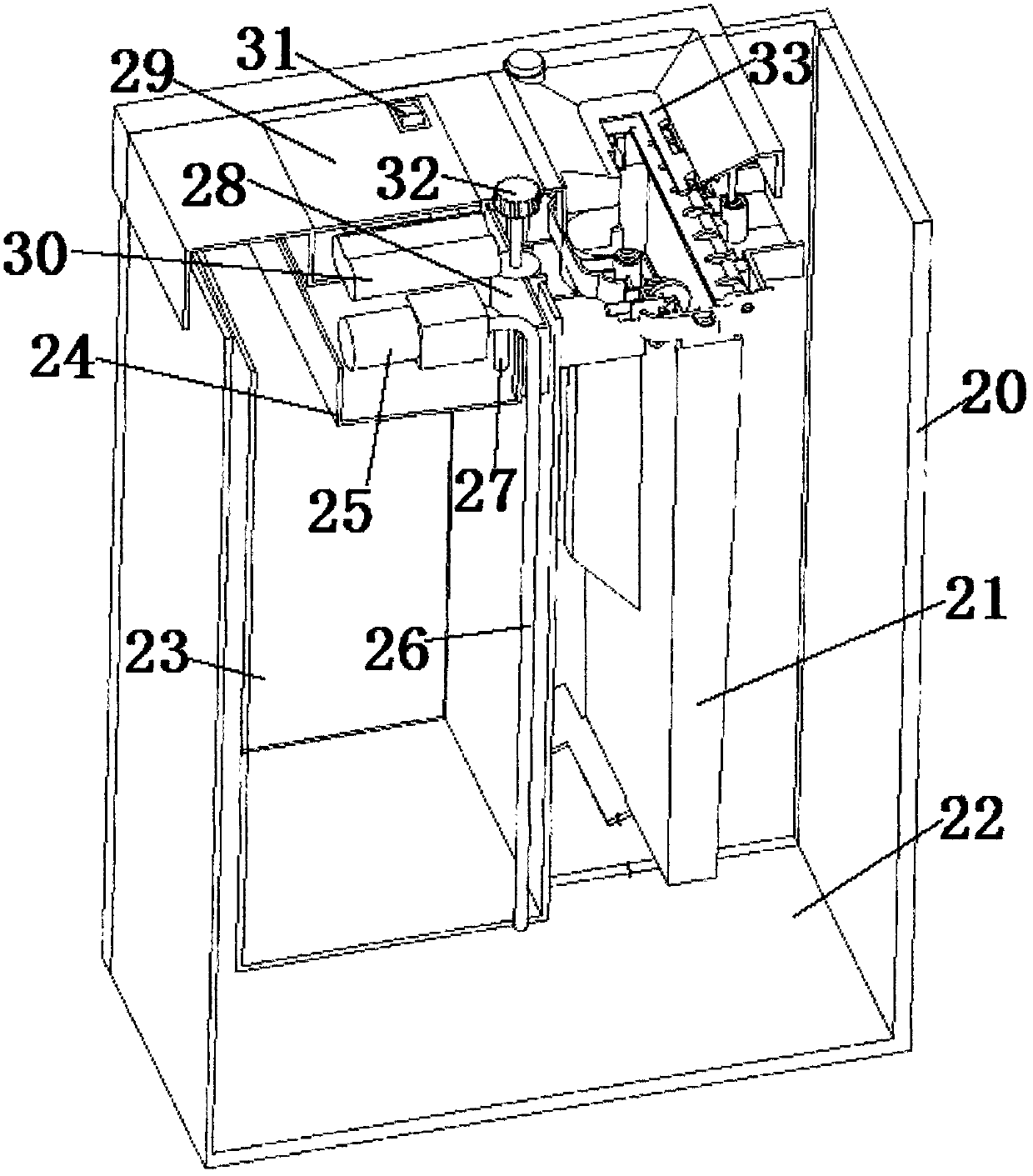

[0057] A flat mop cleaning bucket described in Embodiment 2 includes a bucket body 20, a water purification area, a cleaning area 21, and a sewage area 22, and the water purification area includes a water purification area body 23, a water outlet area 24, and a water purification area body water pump 25 One end of the water purification area body water pump 25 is communicated with the water purification area body 23 through the water pump 26, and the other end is communicated with the water outlet area 24 through the water injection pipe 27, so that the purified water in the water purification area body 23 can pass through the water purification area The body water pump 25 draws into the water outlet area 24 .

[0058] The water purification area and the cleaning area 21 are communicated through the water purification area valve 28 arranged between the water outlet area 24 and the cleaning area 21. The water purification area valve 28 is provided with a knob 32 connected with a...

Embodiment 3

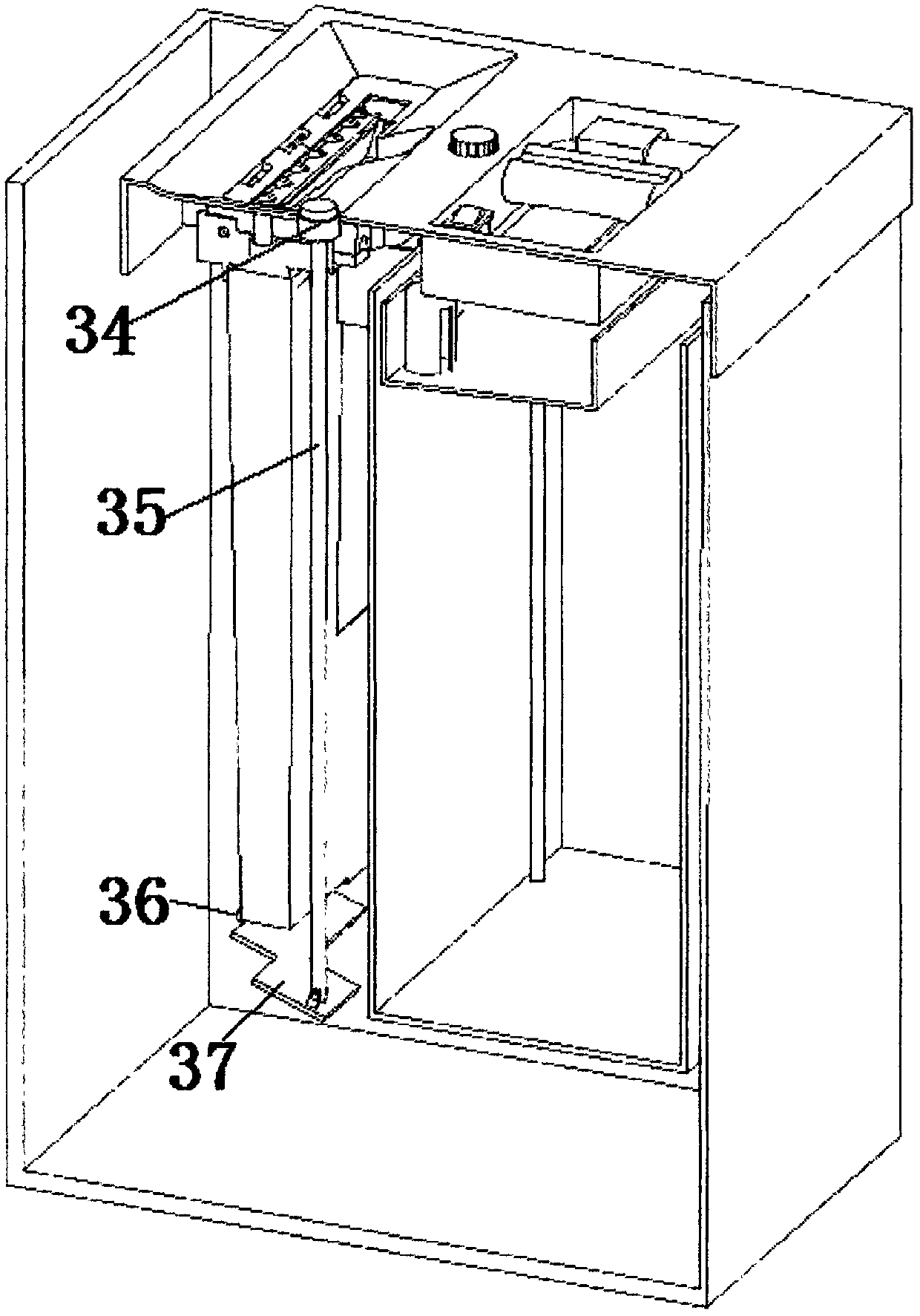

[0064]Embodiment 3 is basically the same as Embodiment 1, the difference lies in the connection mode between the water outlet area and the water outlet pipe. The bottom of the water outlet area 4 is provided with a water outlet hole 41 at the connection with the water inlet pipe 7, and the water outlet area 4 is connected to the water outlet hole 41. A sealing chamber 44, a second spring 48, a second sealing plug 46 movable in the sealing chamber 44, and a sliding block 47 are arranged at the place. One end of the second spring 48 is against the top of the sealing chamber 44, and the other end is against the top of the sealing chamber 47 through the sliding block 47. Two sealing plugs 46, the sliding block 47 is matched with the sealing cavity 44, so as to ensure that the second sealing plug 46 can accurately plug the water outlet hole 41, and the water inlet pipe 7 communicates with the water outlet area 4. One end is provided with a top block 42 for inserting into the water ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com