Mixing method on basis of metering mixing systems

A technology of mixing and mixing cylinders, which is applied in the field of mixing materials based on metering mixing systems, can solve the problems of inaccurate output, affecting the production process, reducing the production efficiency and production quality of industrial lines, and improving production efficiency. and production quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

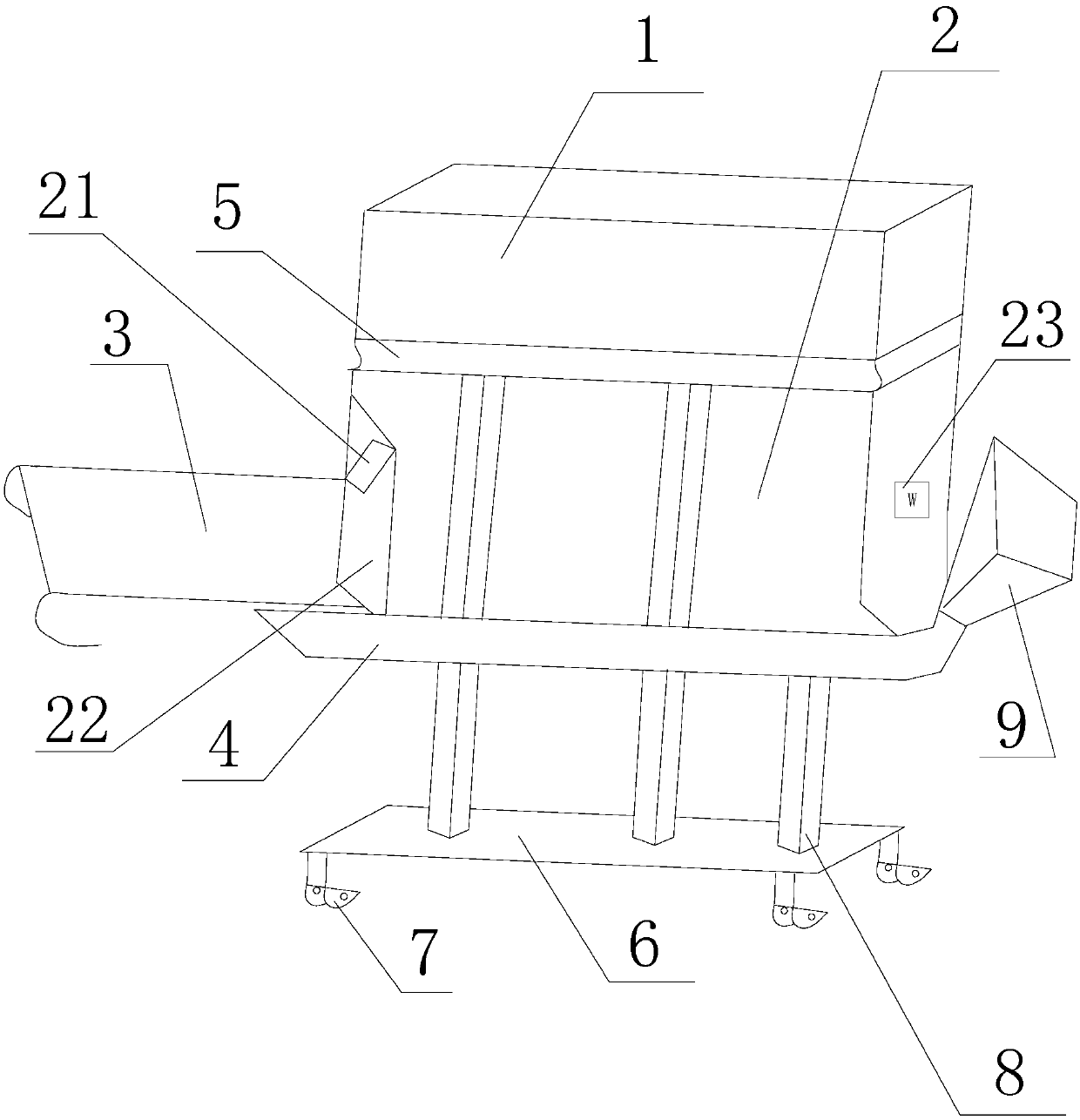

[0017] refer to figure 1 , a metering mixing system, including a main body and a control system, the main body includes a mixing barrel 1 arranged on the main body, a fixing plate 6 arranged below the mixing barrel 1, and a metering bin 2 connected to the mixing barrel 1; the metering bin 2 are respectively provided with a discharge port 22, a weighing module 23 and a control valve 21 for controlling the opening and closing of the discharge port 22, and the control valve 21 and the weighing module 23 are respectively connected with the control system; the bottom corner of the fixed plate 6 There are sliding wheels 7 for facilitating the movement of the main body.

[0018] Specifically, in this embodiment, the mixing cylinder 1 is made of stainless steel, which is stable and durable, and is suitable for large-scale industrial production lines; the control system is a PLC control system, and the PLC control system, that is, a programmable logic controller, is designed for An el...

Embodiment 2

[0023] A kind of mixing method based on the metering mixing system of the present invention comprises the following steps: A, the control system controls the drive motor 9 to open, and the color material is sent into the mixing cylinder 1 for mixing; B, the mixing cylinder The color material that has been mixed in 1 is continuously sent into the metering bin 2, and the weight information of the color material is continuously obtained by the weighing module 23;

[0024] C. Feedback the weight information to the control system. The control system compares the weight of the colorant with the preset upper and lower weight limits, and controls the opening or closing of the drive motor 9 and the control valve according to the comparison results to control the discharge port. 22 on or off.

[0025] According to the real-time weight of the color material in the metering bin 2, the present invention can intelligently control the opening or closing of the discharge port 22 and the drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com