a paint spray gun

A spray gun and paint technology, applied in the direction of spray device, liquid spray device, etc., can solve the problems of spray gun clogging and unsmooth spraying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

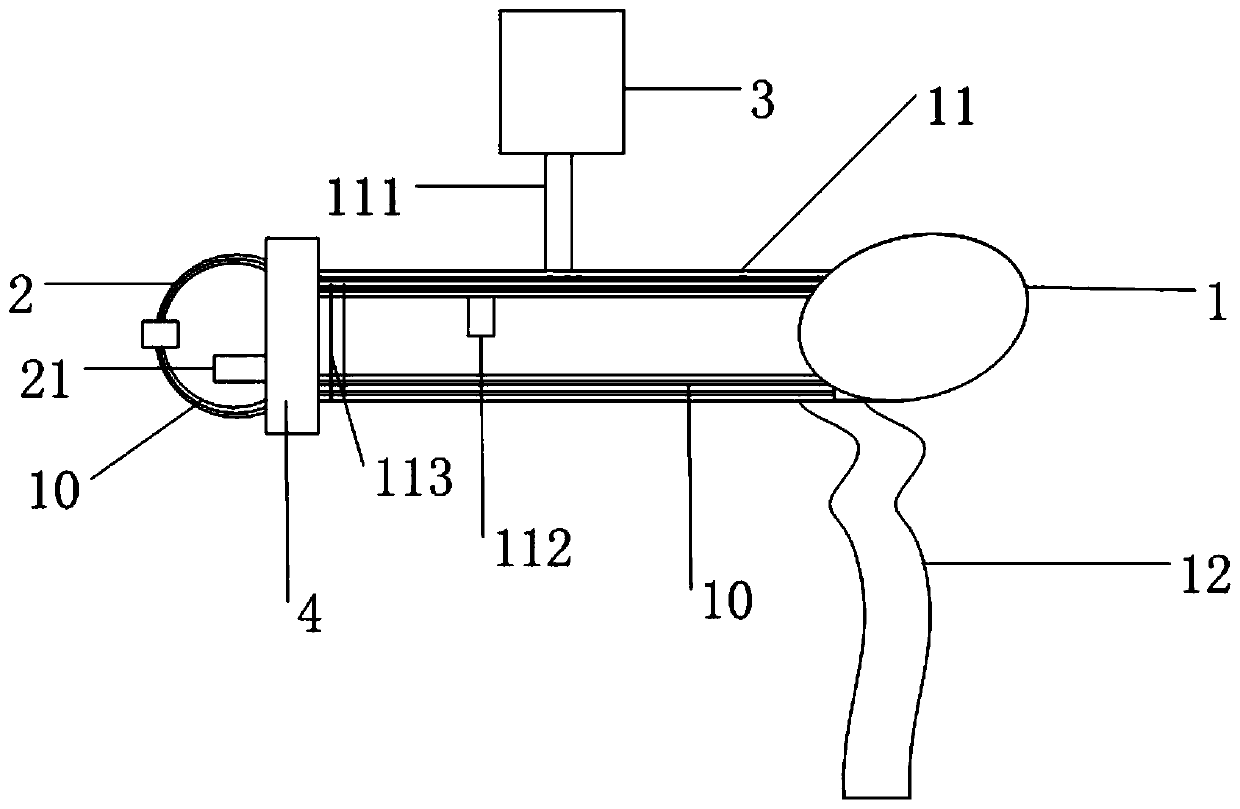

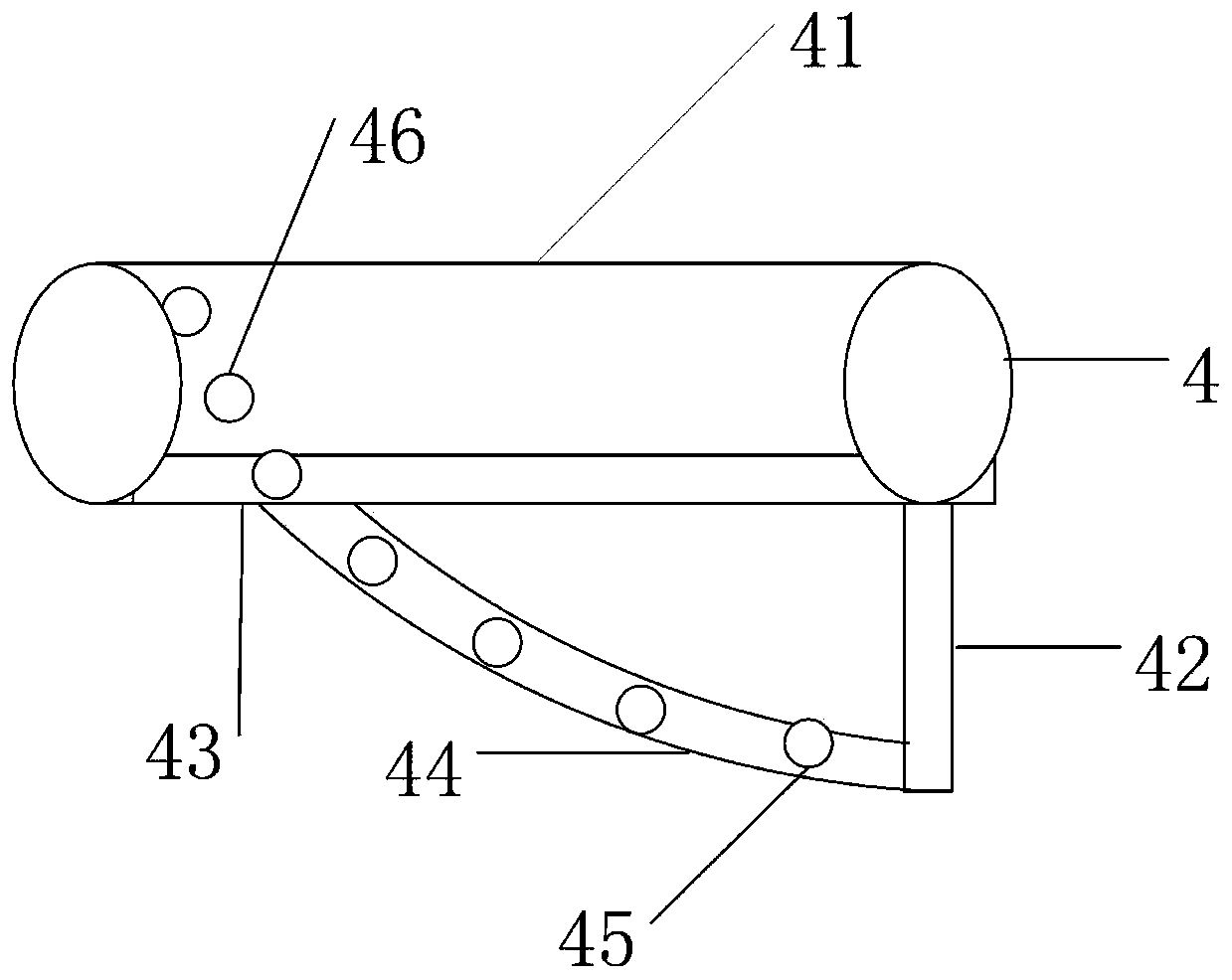

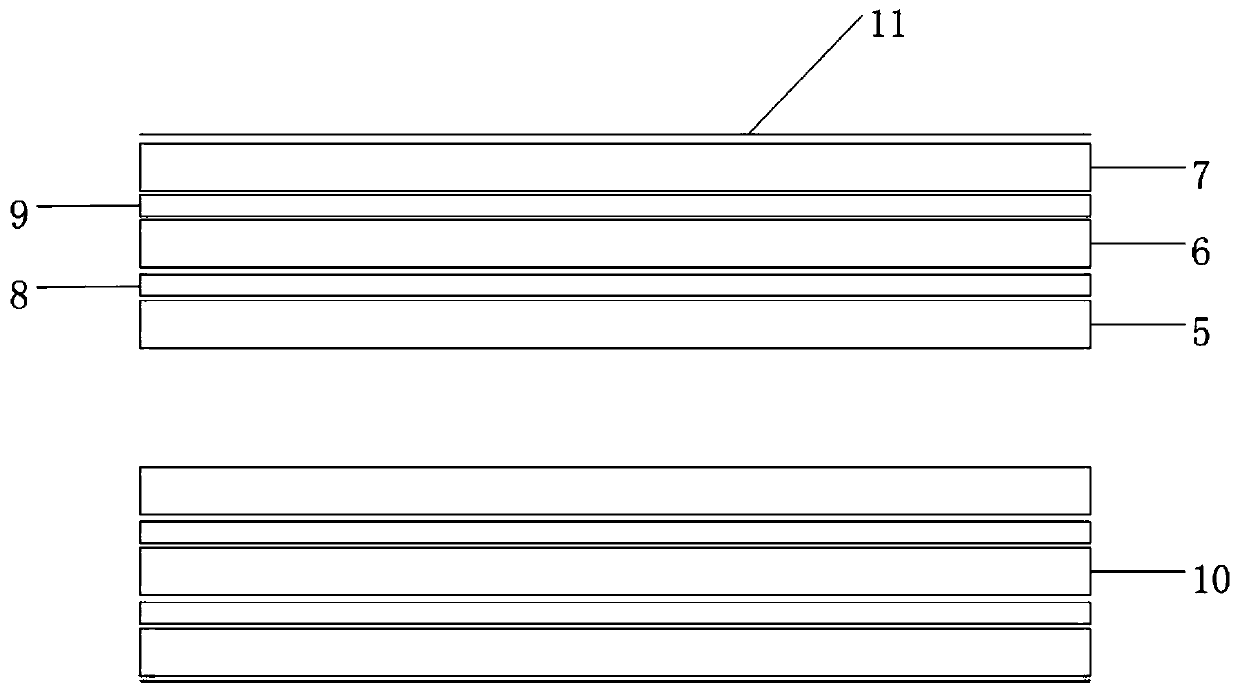

[0023] see figure 1 , a structural schematic diagram of a paint spray gun provided for the application. The paint spray gun includes a gun body 1, a nozzle 2 and a paint can 3, wherein the gun body 1 includes a nozzle 11 and a handle 12, one end of the nozzle 11 is connected to the handle 12, and the other end of the nozzle 11 and the nozzle 2 are movable through the connector 4 connected, the nozzle 2 is a hollow cavity. A connecting pipe 111 is arranged on the spray pipe 11, and the connecting pipe 111 is flexibly connected with the paint can 3. During the use of the paint spray gun, the paint in the paint tank 3 reaches the spray pipe 11 through the connecting pipe 111 . The inside of the nozzle 11 is provided with a first stirring member 112 at a position close to the nozzle 2. After the paint is mixed and stirred by the first stirring member 112, the density and viscosity of the paint will be reduced, so that the spraying process of the paint is relatively smooth, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com