Patents

Literature

40results about How to "Jet evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

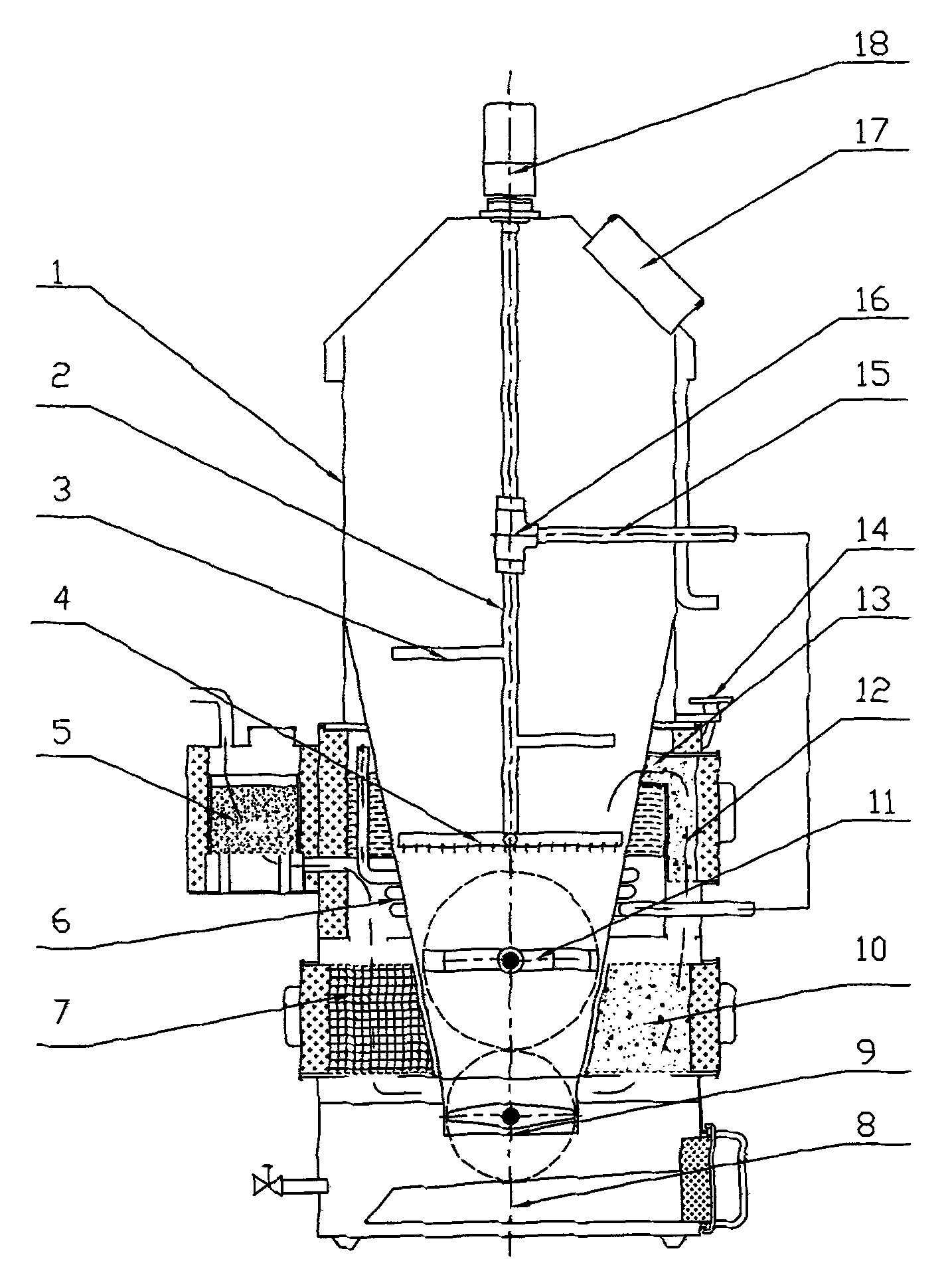

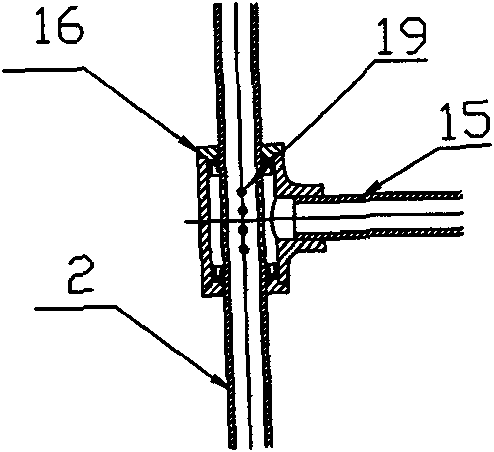

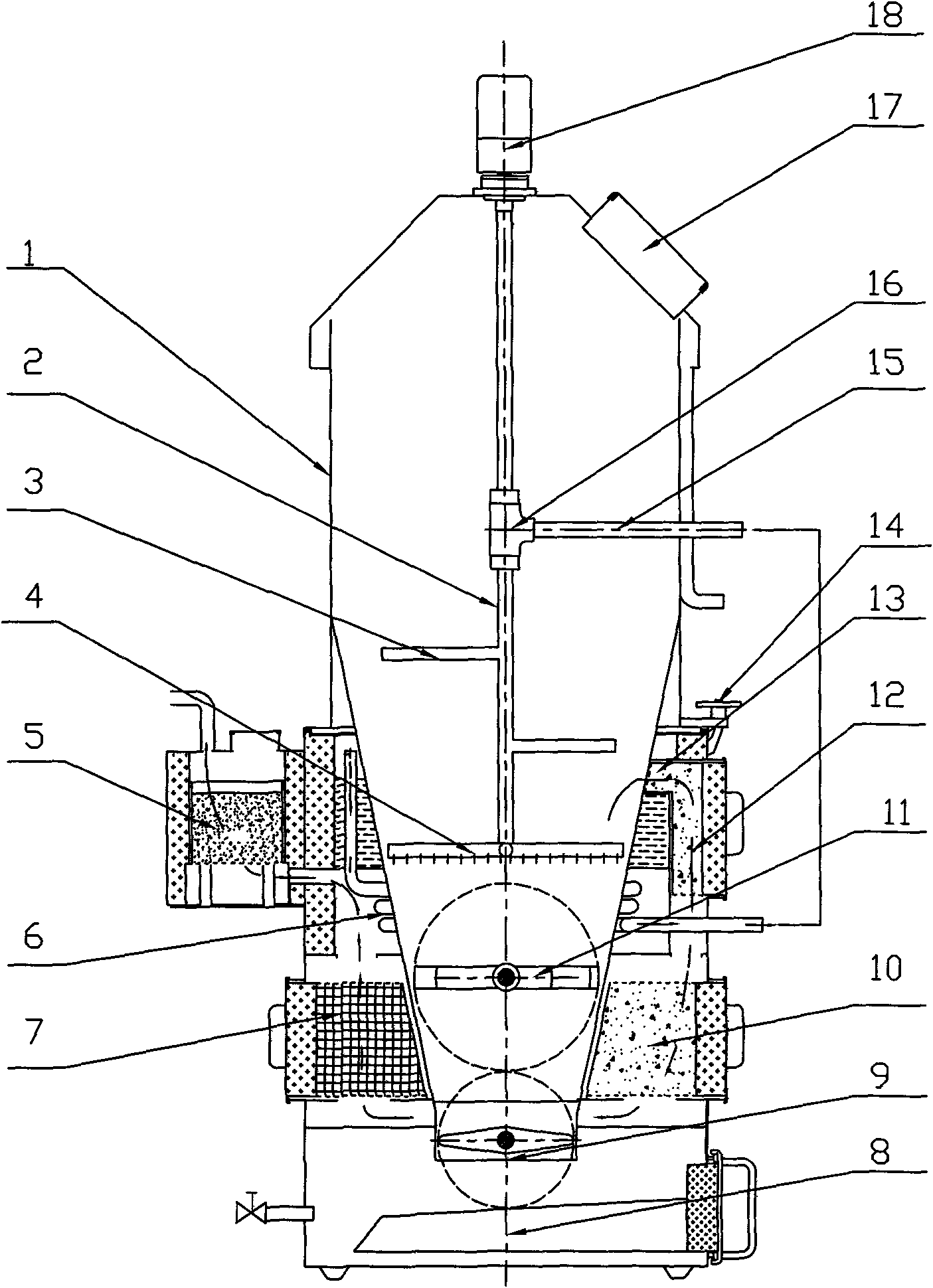

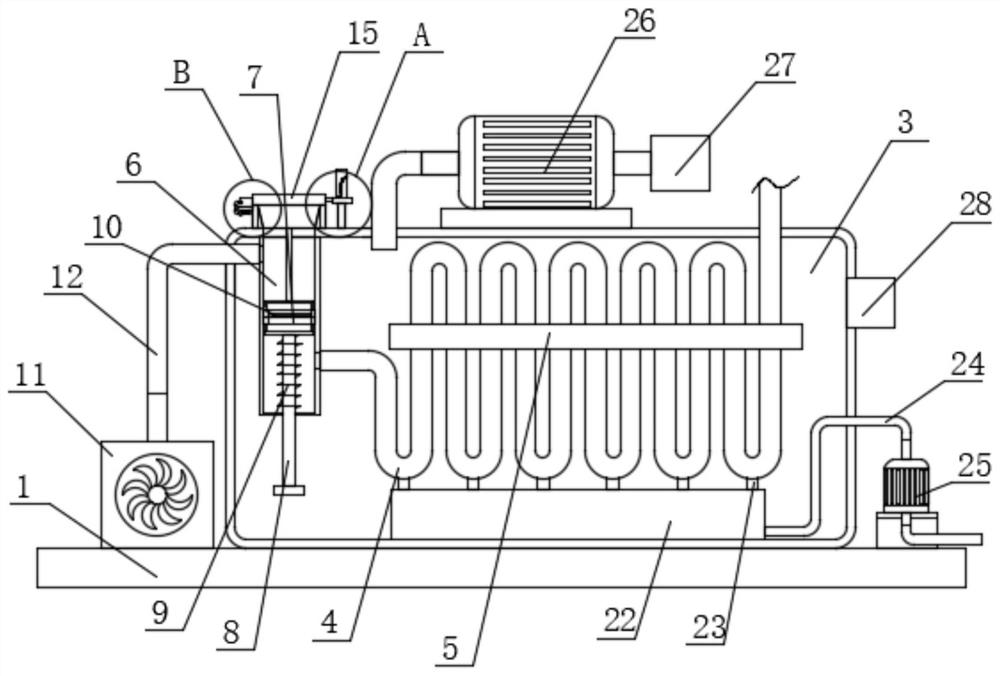

Gasification agent injection device of biomass gasifier

The invention discloses a gasification agent injection device of a biomass gasifier, which comprises a gasification agent inlet pipe, a gasification agent outlet pipe erected in a gasifier body, an electric or manual speed reducer positioned at the top of the gasifier and an air inlet three-way joint fixed in the gasifier body, wherein the upper part of the gasification agent outlet pipe runs through upper and lower ports of the three-way joint to be connected with a main shaft of the speed reducer and to rotate along with the main shaft of the speed reducer under the positioning of the gas inlet three-way joint; the part of the gasification agent outlet pipe in the three-way joint is provided with a plurality of air inlets; the lower end of the gasification agent outlet pipe is communicated with at least one gasification agent injection pipe with a plurality of air injection holes; a transverse port of the air inlet three-way joint is connected with the gasification agent inlet pipe;joints between the gasification inlet pipe and the port of the air inlet three-way joint and between the gasification agent outlet pipe and the port of the air inlet three-way joint are in the state of high-temperature oil seal; and the outer pipe wall of the gasification gas outlet pipe is also provided with a material stirring device.

Owner:周少海 +1

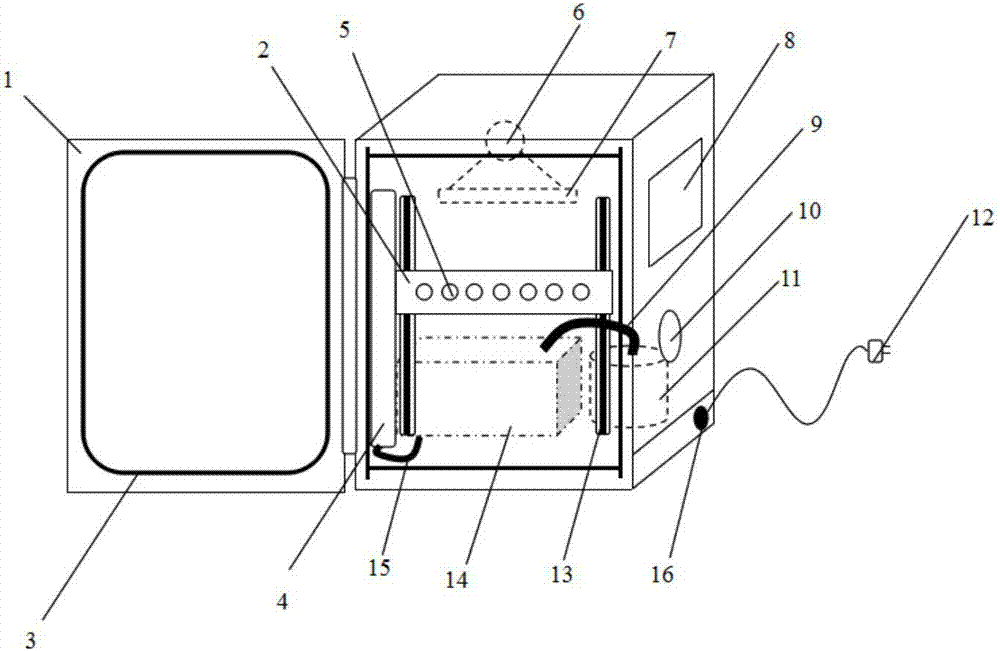

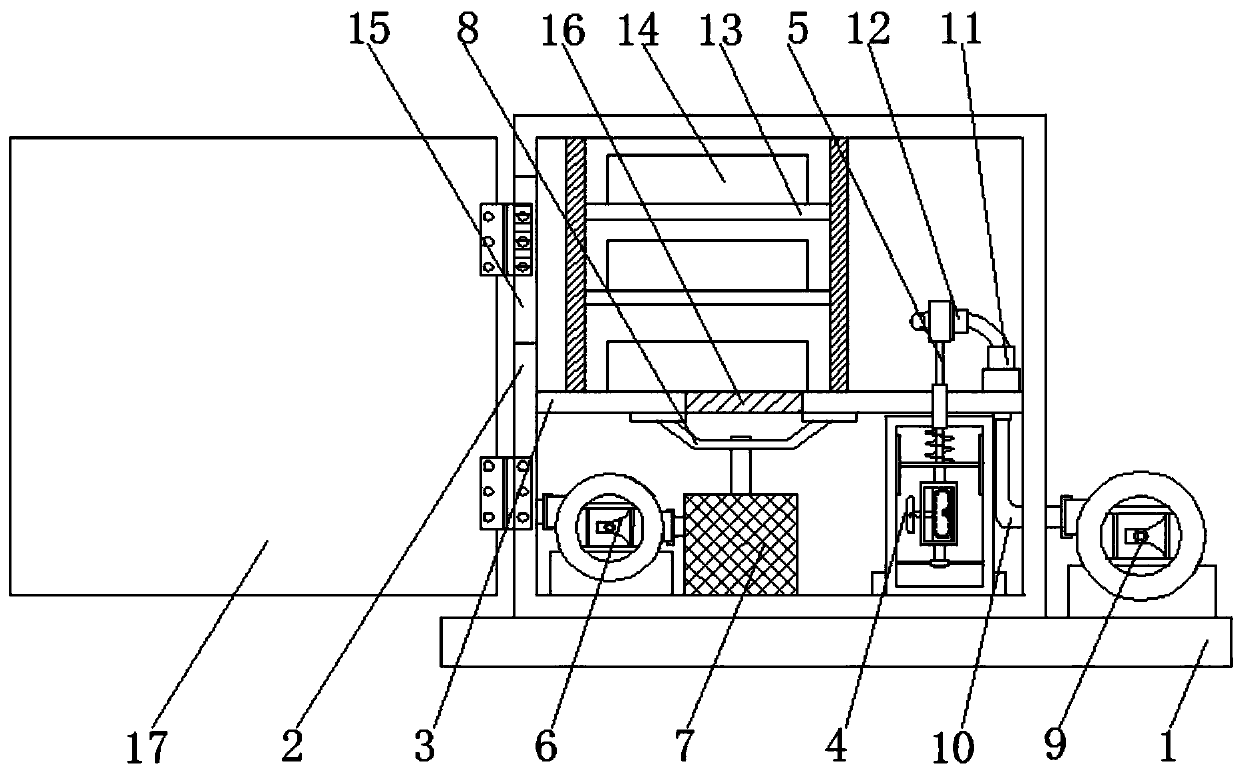

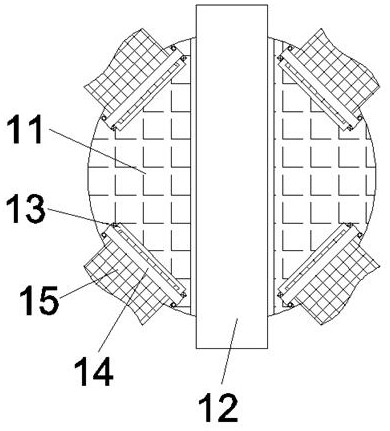

Power distribution box with high heat dissipation performance

ActiveCN107332134ASolve uneven heat dissipationReduce maintenance and replacement frequencySubstation/switching arrangement cooling/ventilationMechanical energy handlingTransmission delayEngineering

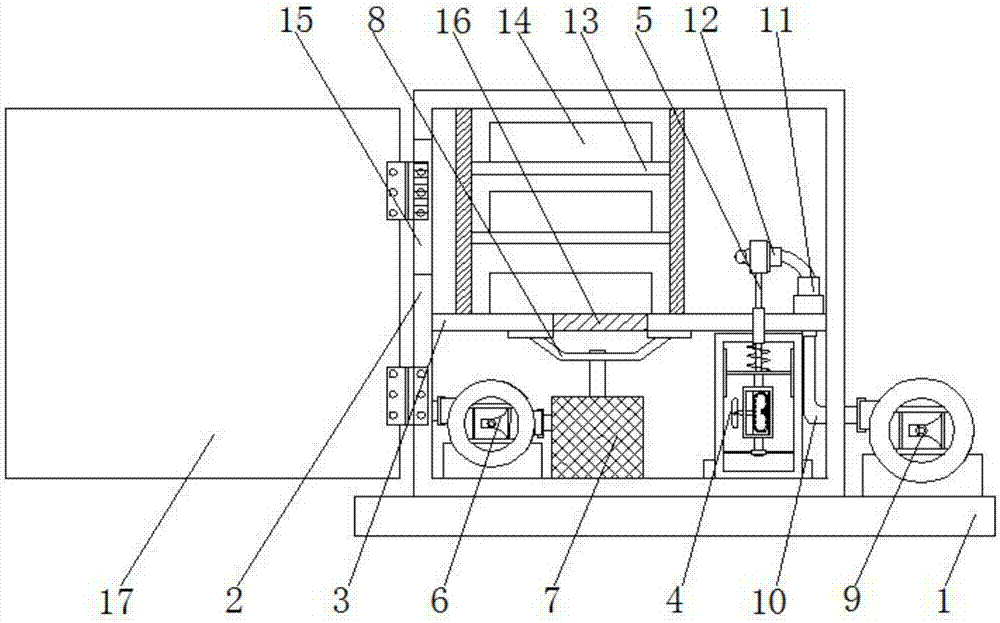

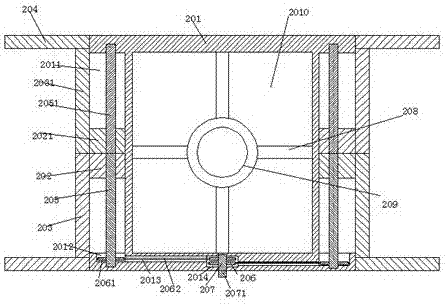

Disclosed is a power distribution box with high heat dissipation performance. The power distribution box comprises a base, a box body is fixedly connected at the top of the base, a partition board is fixedly connected between the two opposite sides of the cavity inside the box body, the right side of the bottom of the cavity in the box body is fixedly connected with a transmission device, the top of the transmission device is provided with a support rod in a penetrating manner, the top end of the support rod penetrates the partition board and extends to the top of the partition board, the left side of the bottom of the cavity in the box body is fixedly connected with a first blower, and an exhaust of the first blower runs through the left side of the box body and extends to the outside of the box body. The air outlet of the first blower is connected with a cooler, and the bottom of the cooler is fixedly connected with the bottom of the cavity of the box body. The present invention relates to the technical field of machinery. The power distribution box with high heat dissipation performance solves the problem of uneven distribution of heat in the conventional distribution box, reduces the frequency of inspection and replacement of the electrical components, prevents the electrical components from being damaged due to overheating, and indirectly improves the working electrical components' efficiency.

Owner:SHANGHAI ZHEZHONG ELECTRIC

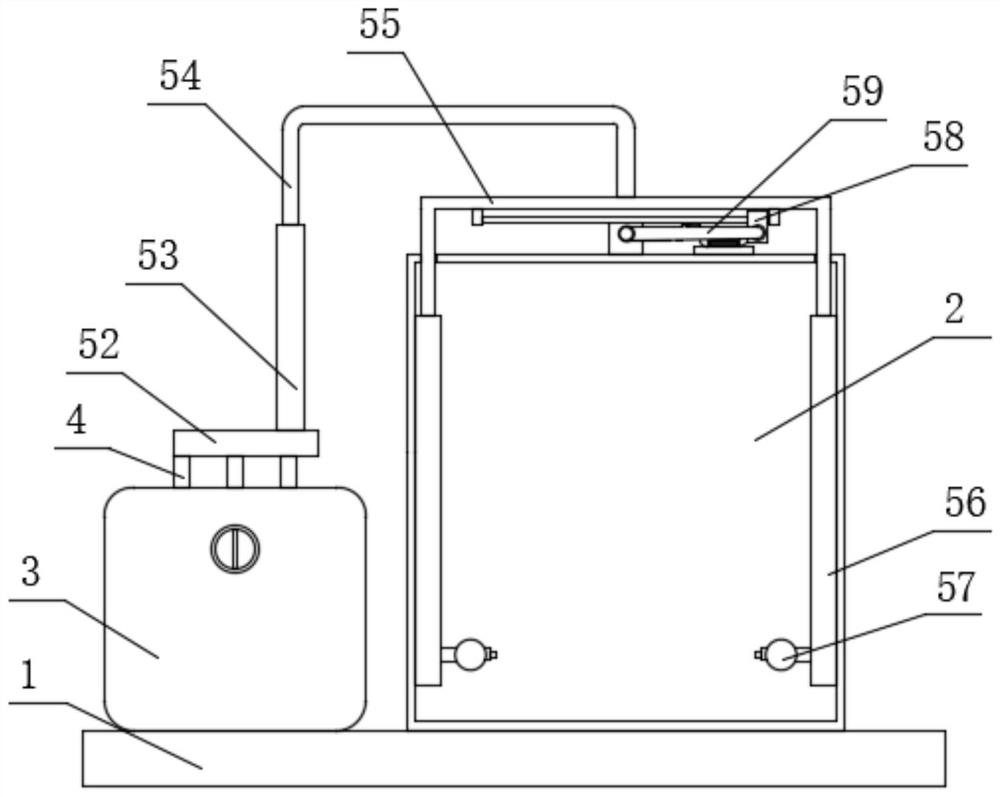

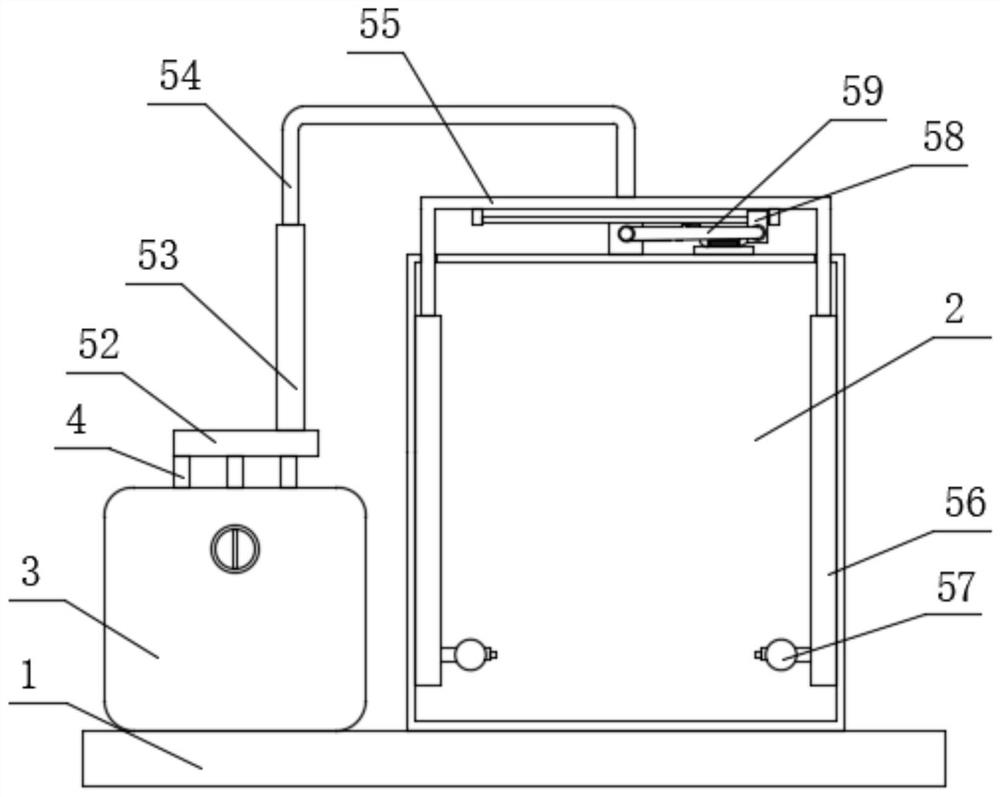

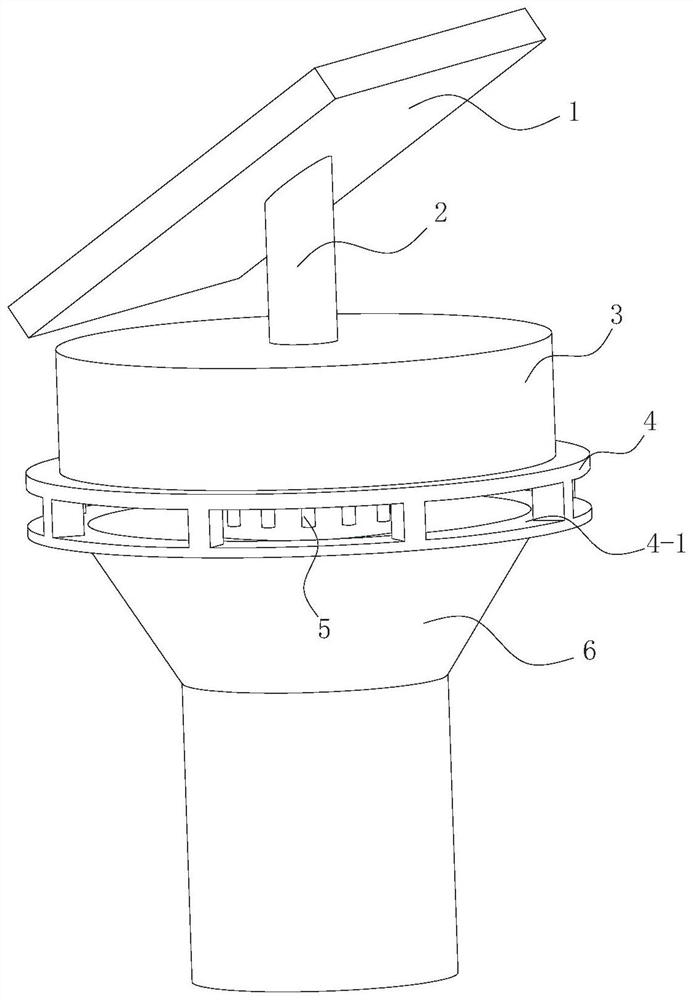

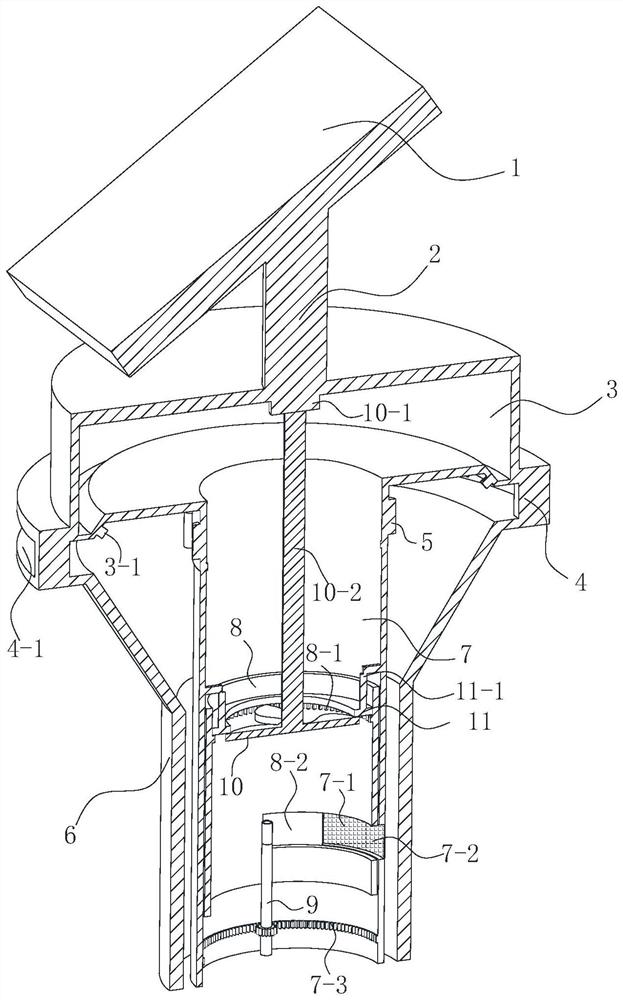

Cooling and ventilating equipment for box-type transformer substation, and using method thereof

ActiveCN112260112ARapid coolingReduce the temperatureSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsTransformerDust control

The invention discloses an application method of cooling and ventilation equipment for a box-type transformer substation. The equipment comprises a base, wherein the top of the base is fixedly provided with a transformer substation box body and a cooling box, the cooling box is located at one side of the transformer substation box body, the inner wall of one side of the top of the cooling box is fixedly provided with a dust removal assembly, a turbofan located on one side of the cooling box is fixedly installed at the top of the base, an air conveying pipe is fixedly installed at the air outlet end of the turbofan, one end of the air conveying pipe extends into the cooling box and communicates with the dust removal assembly, and a fixing plate is fixedly installed in the cooling box. According to the invention, gas entering a transformer substation can be cooled and dried, and uniform gas spraying can be realized after the gas is conveyed into the transformer substation box, so that the transformer substation box can be uniformly and quickly cooled, the temperature in the transformer substation box can be prevented from being too high, and the transformer substation box has good practicability.

Owner:山东德普电力有限公司

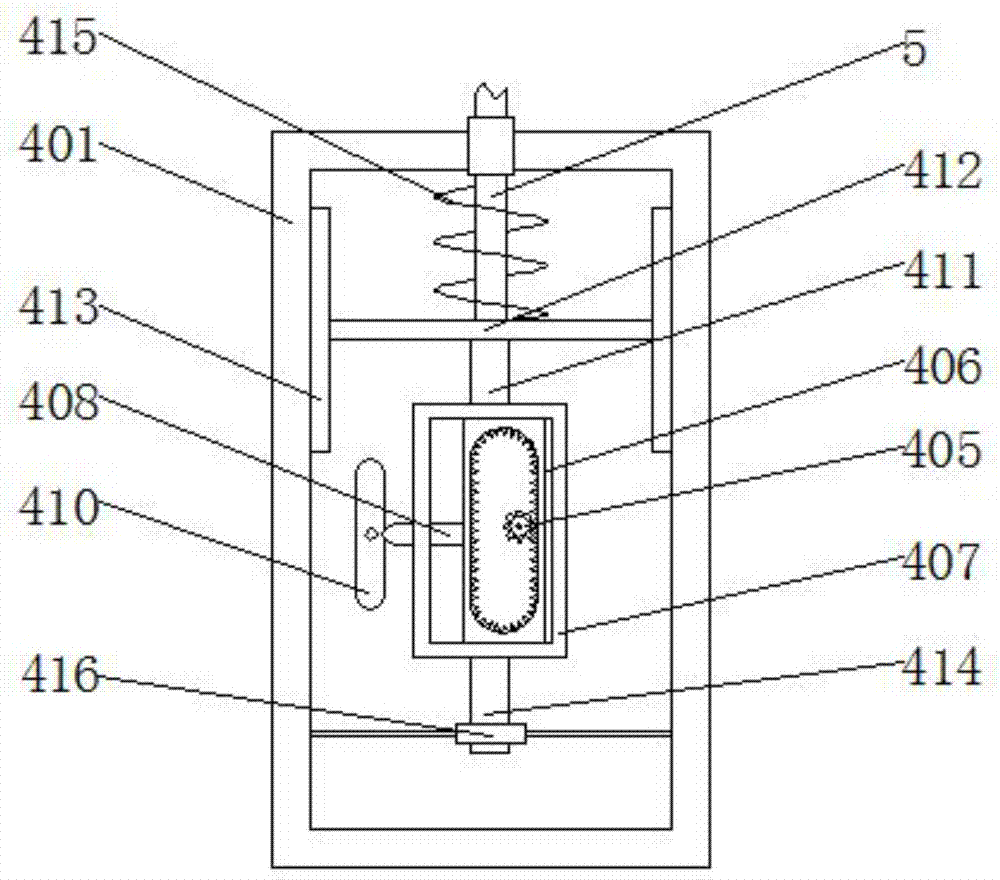

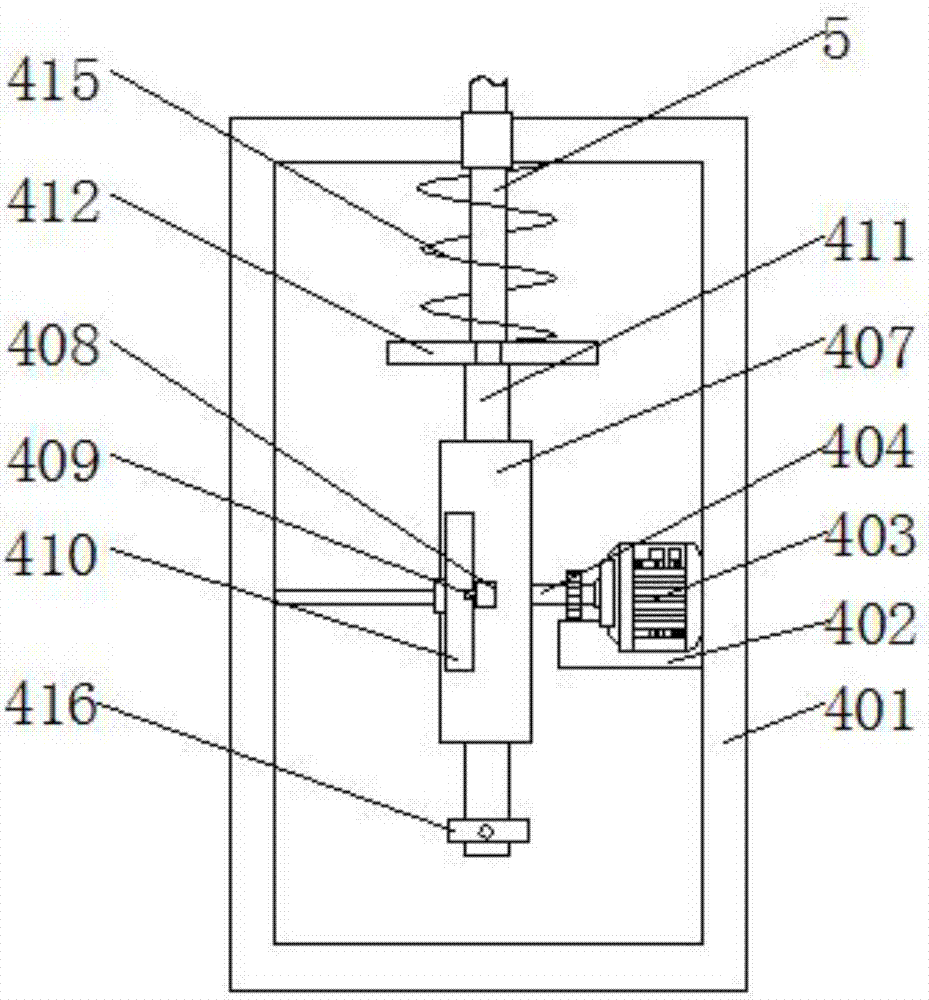

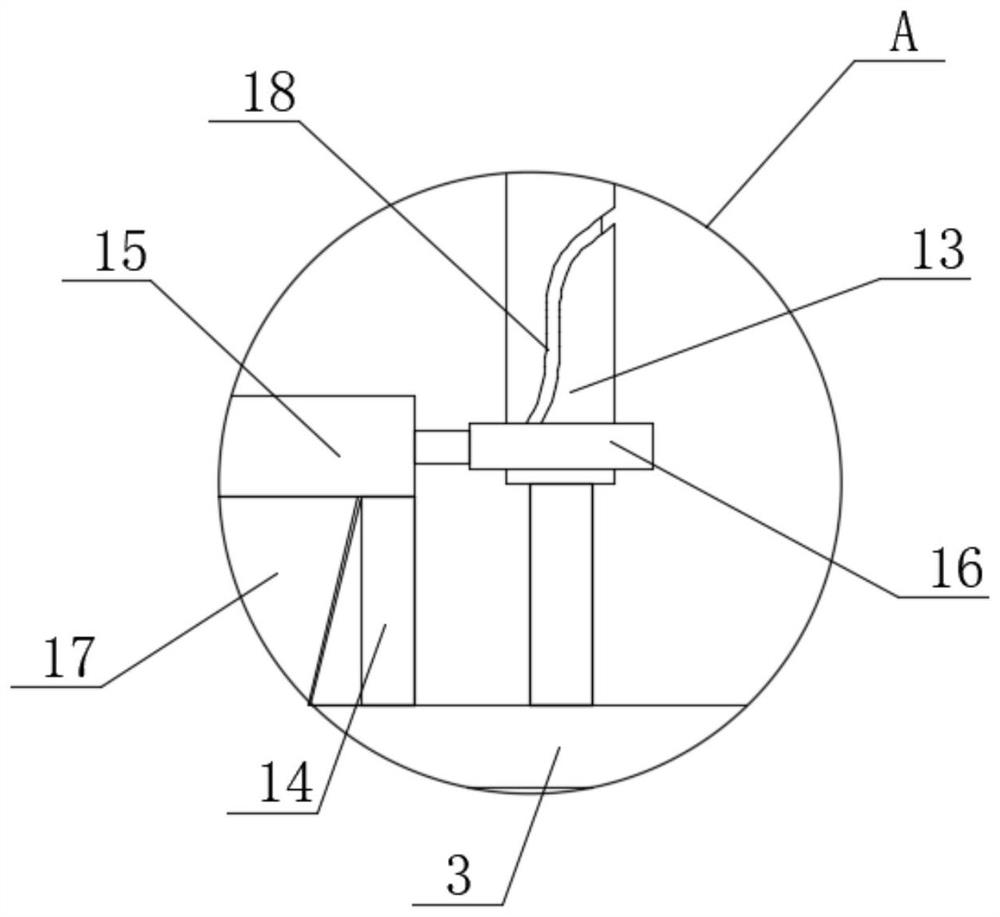

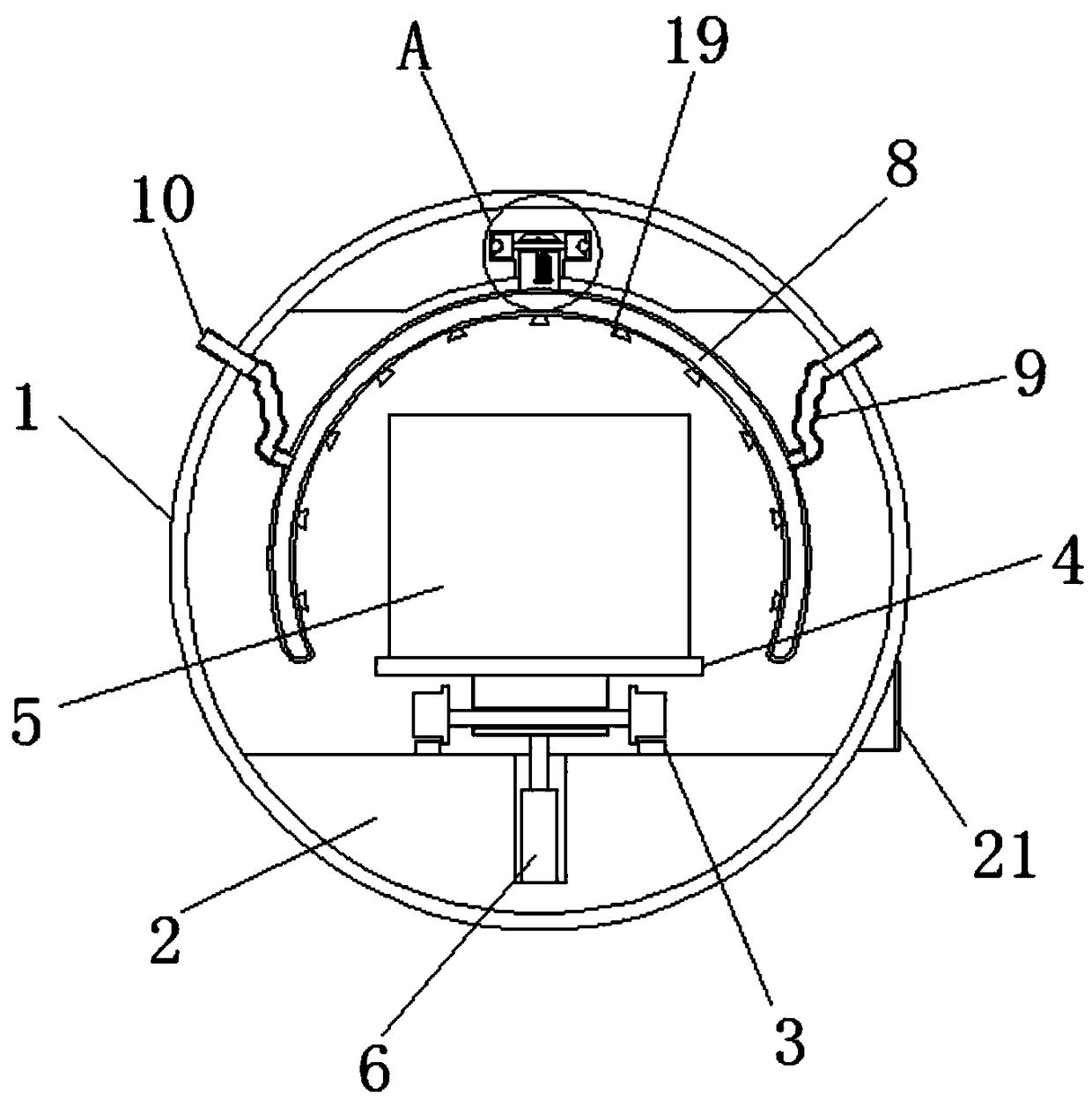

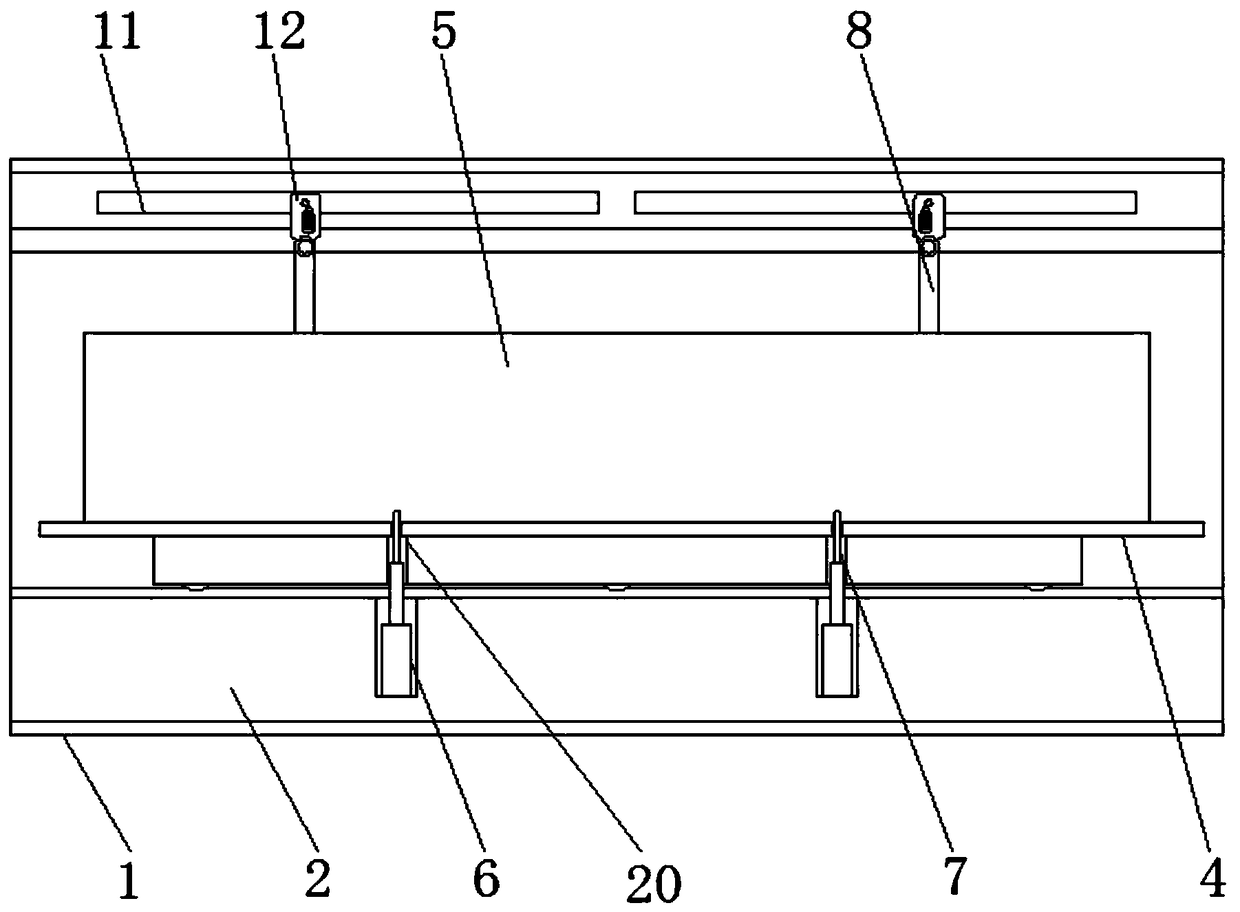

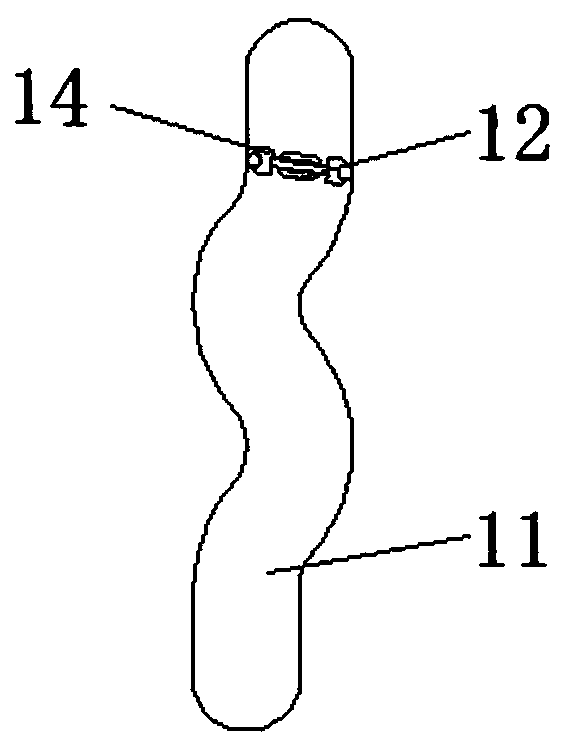

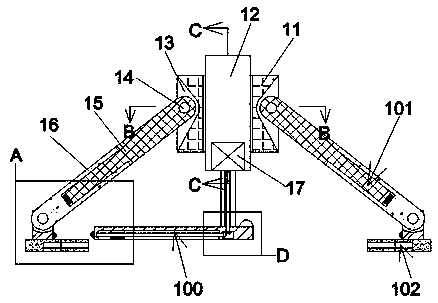

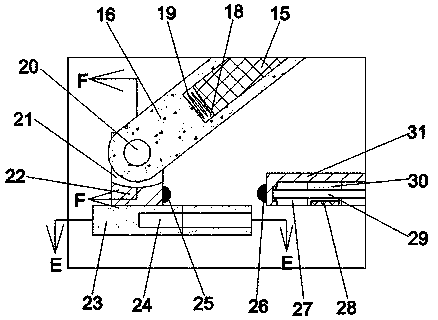

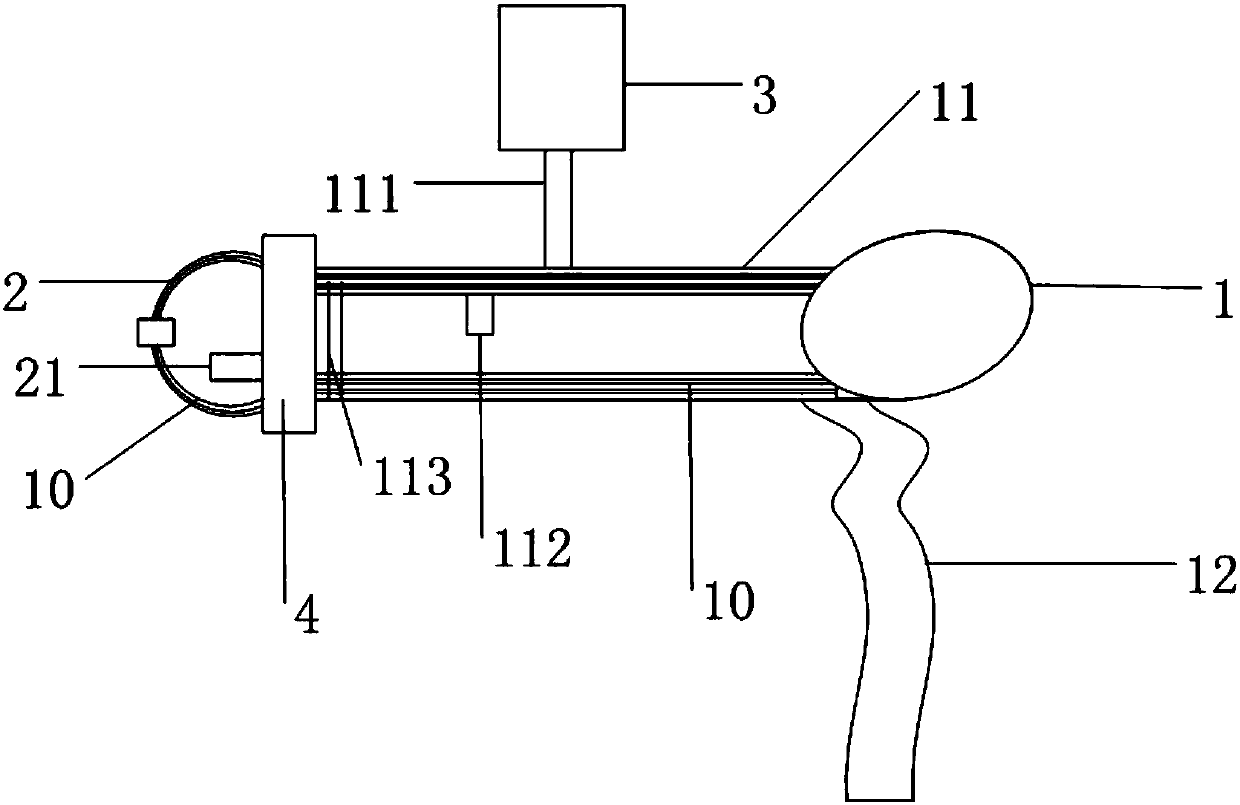

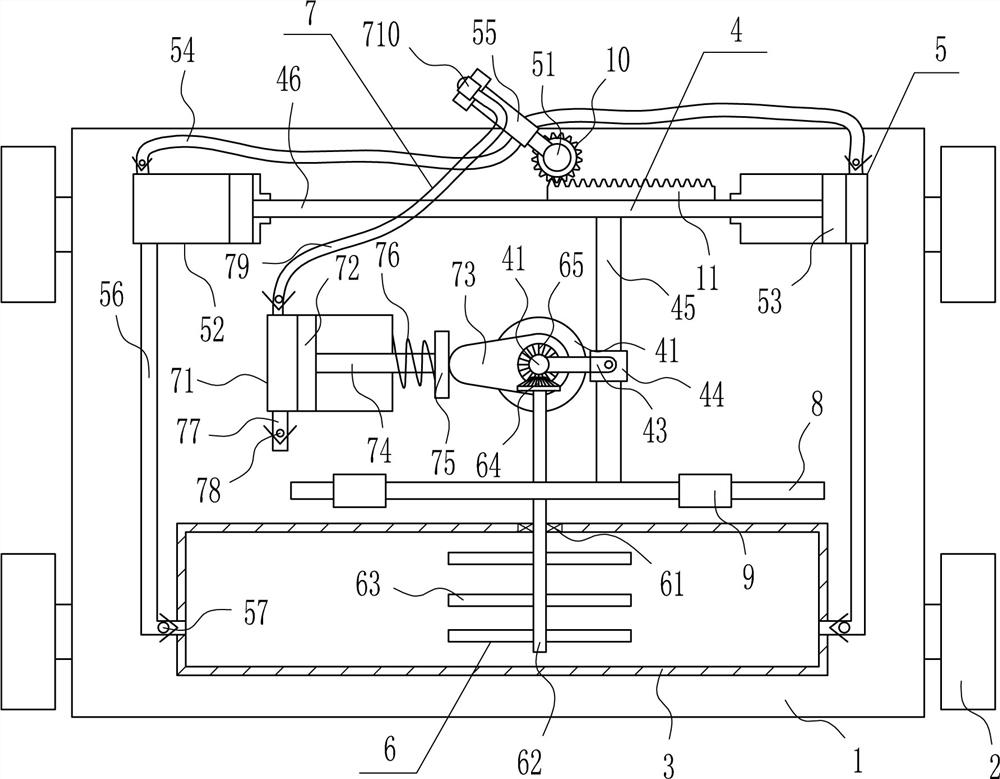

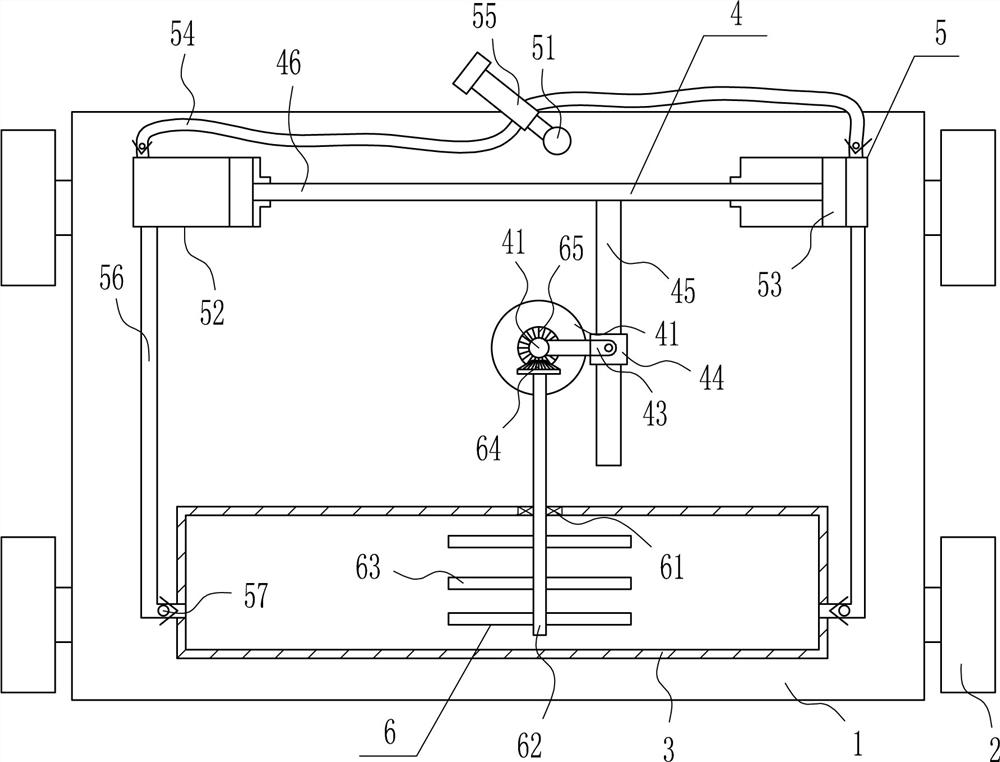

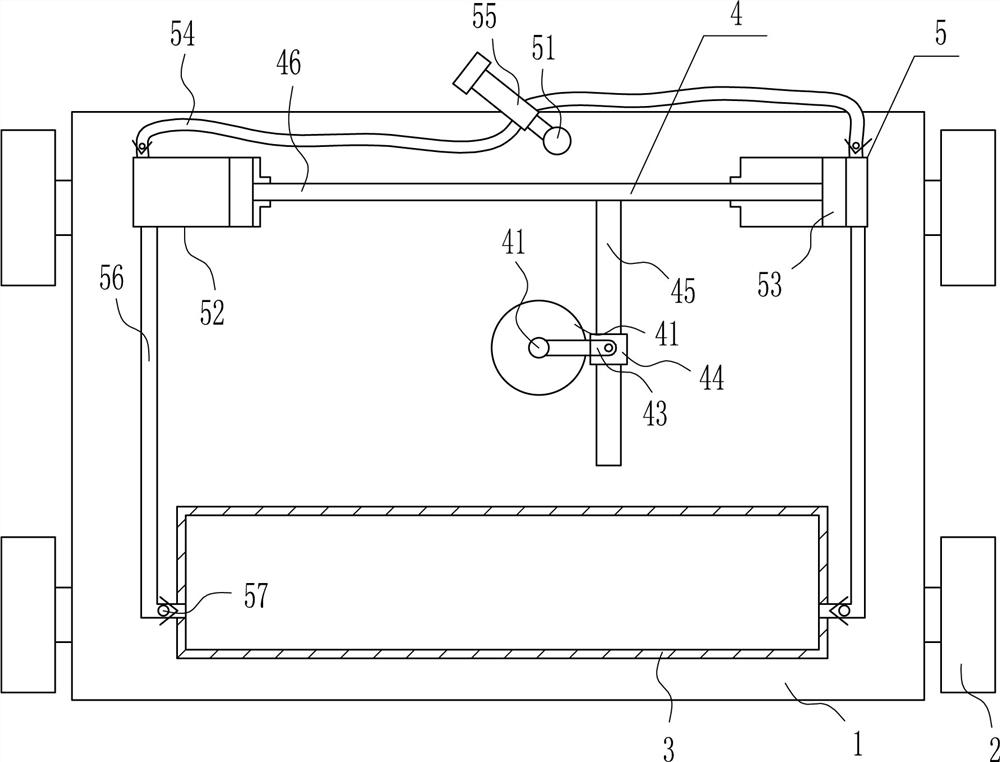

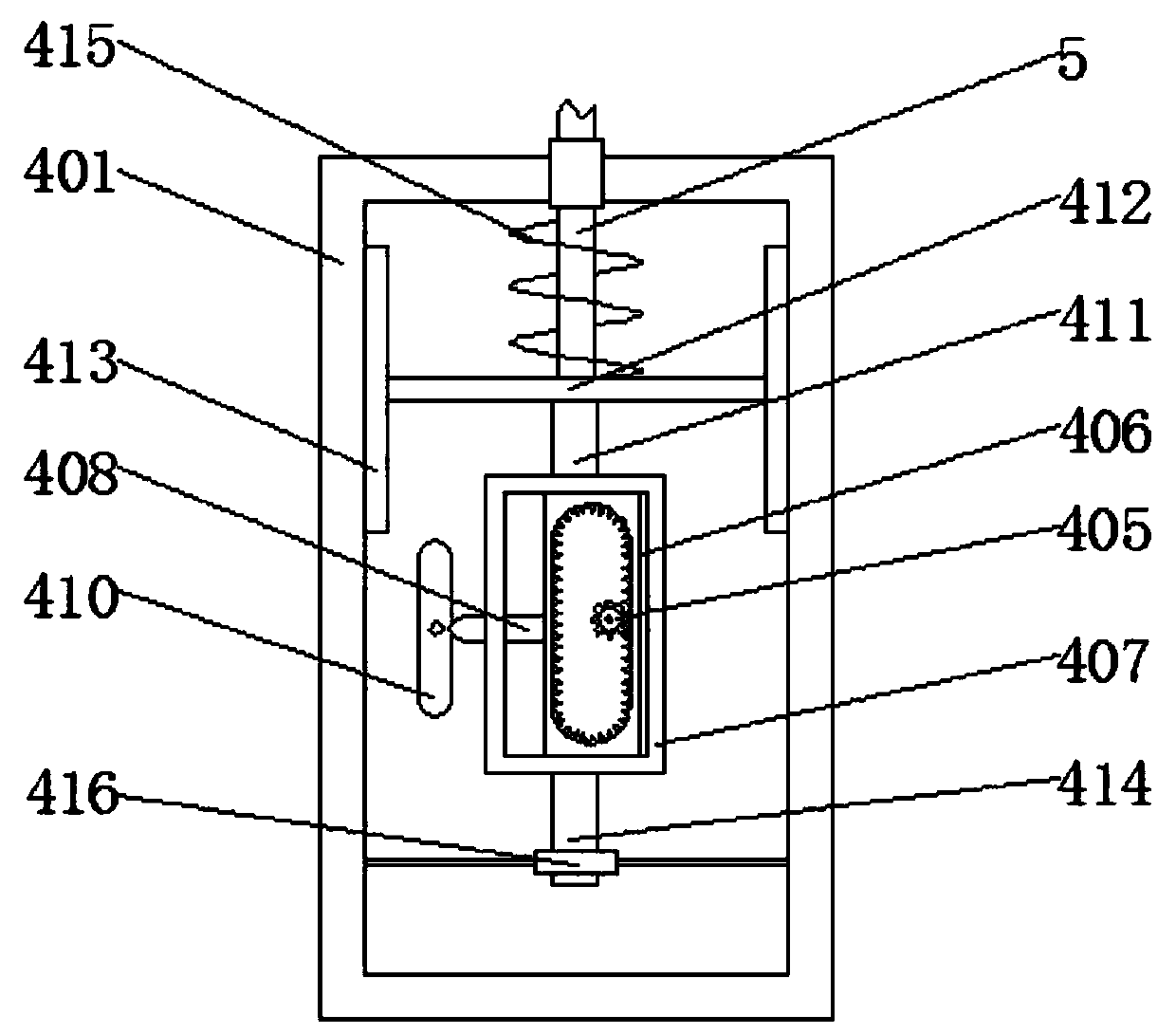

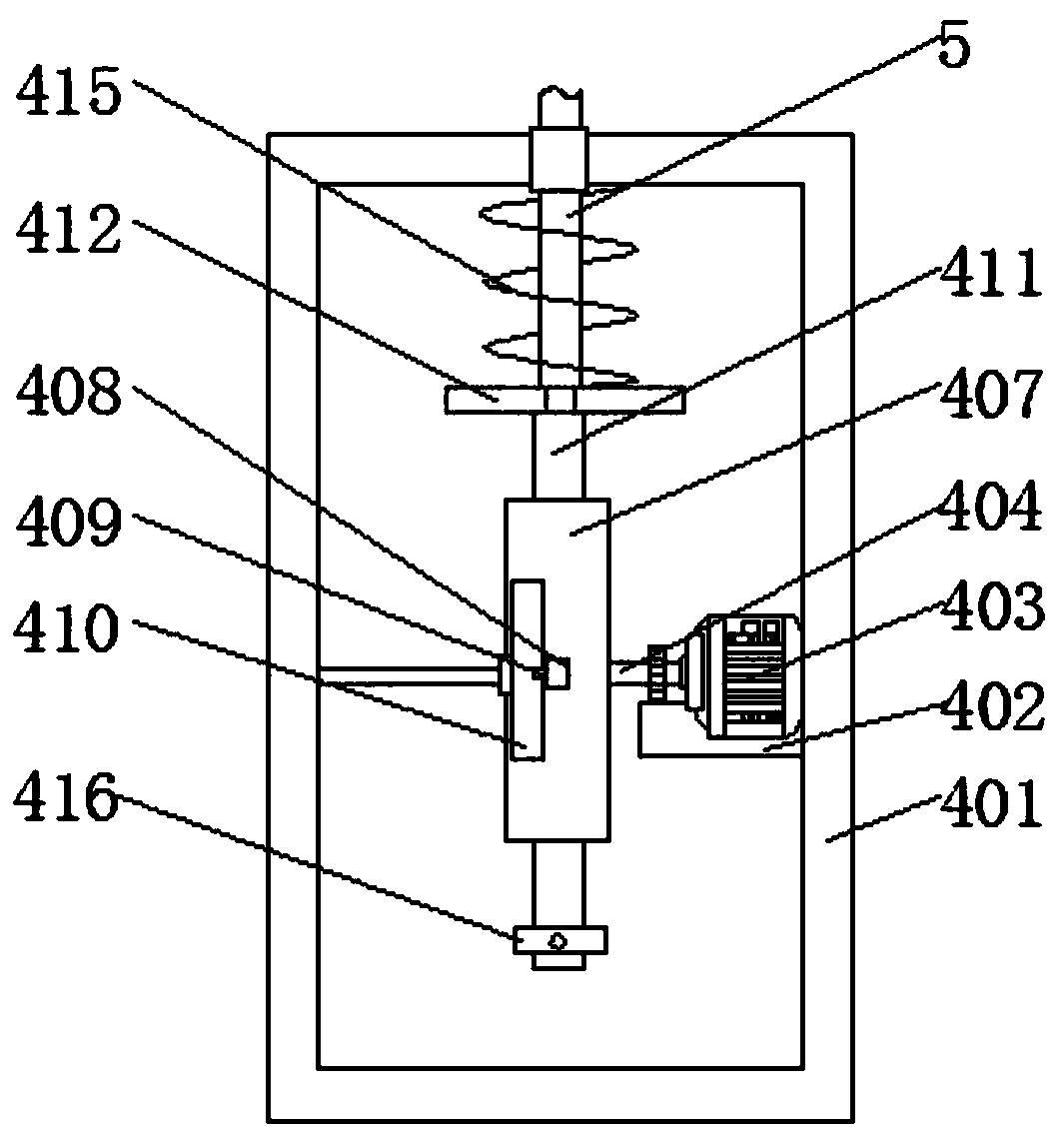

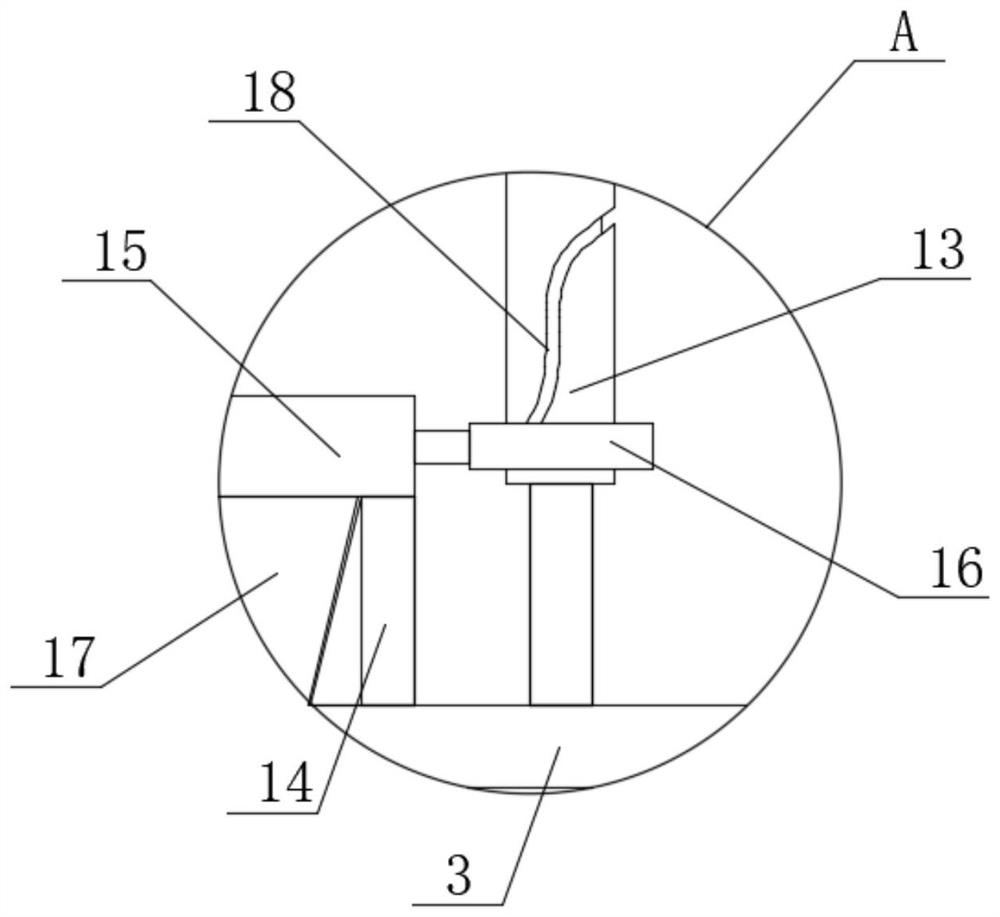

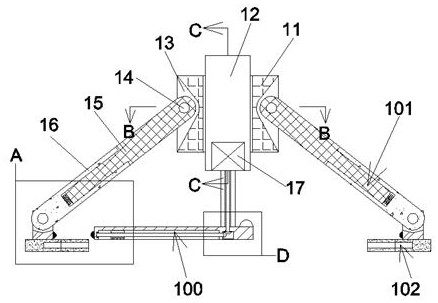

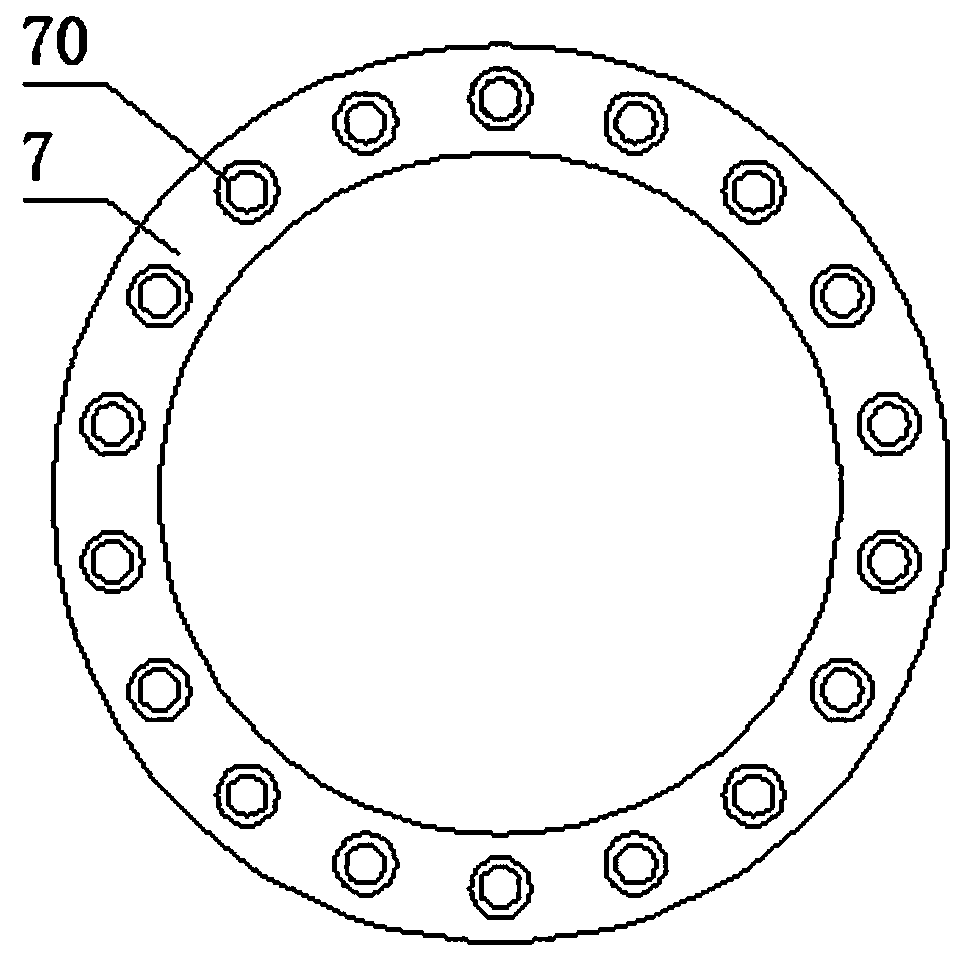

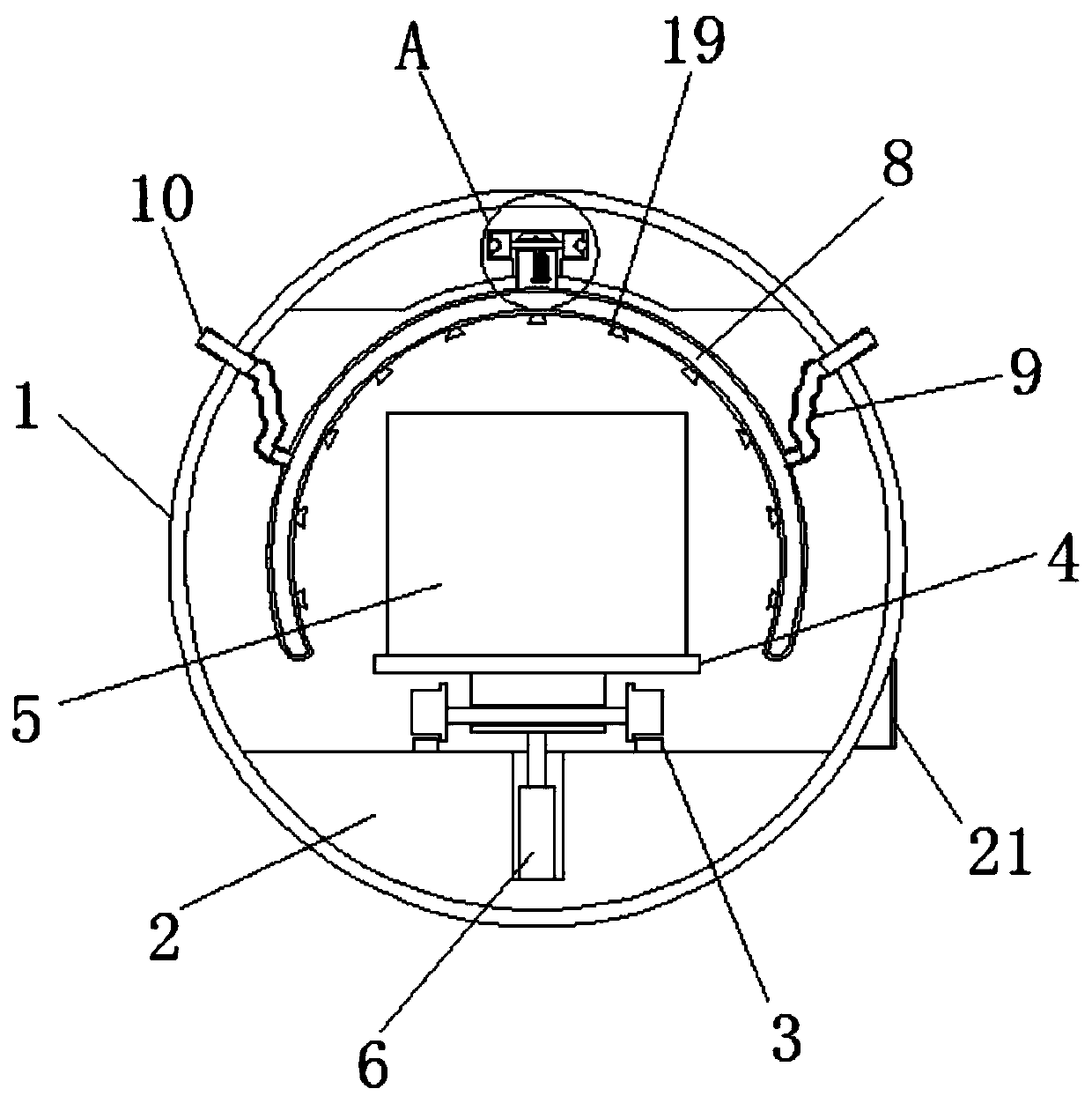

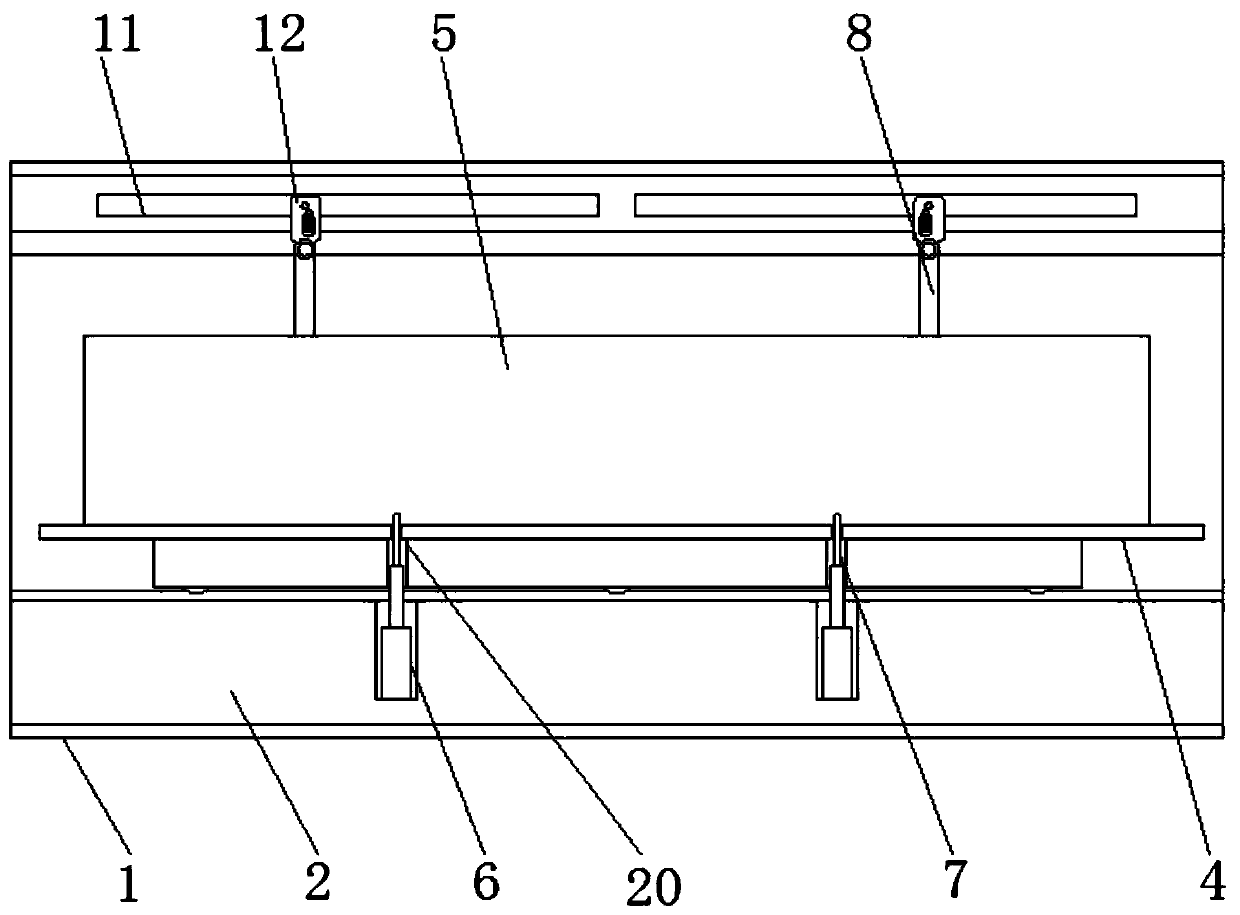

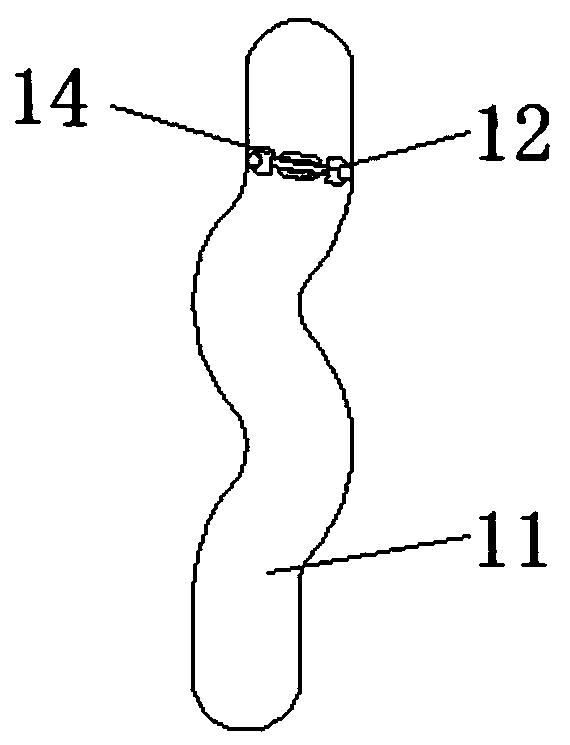

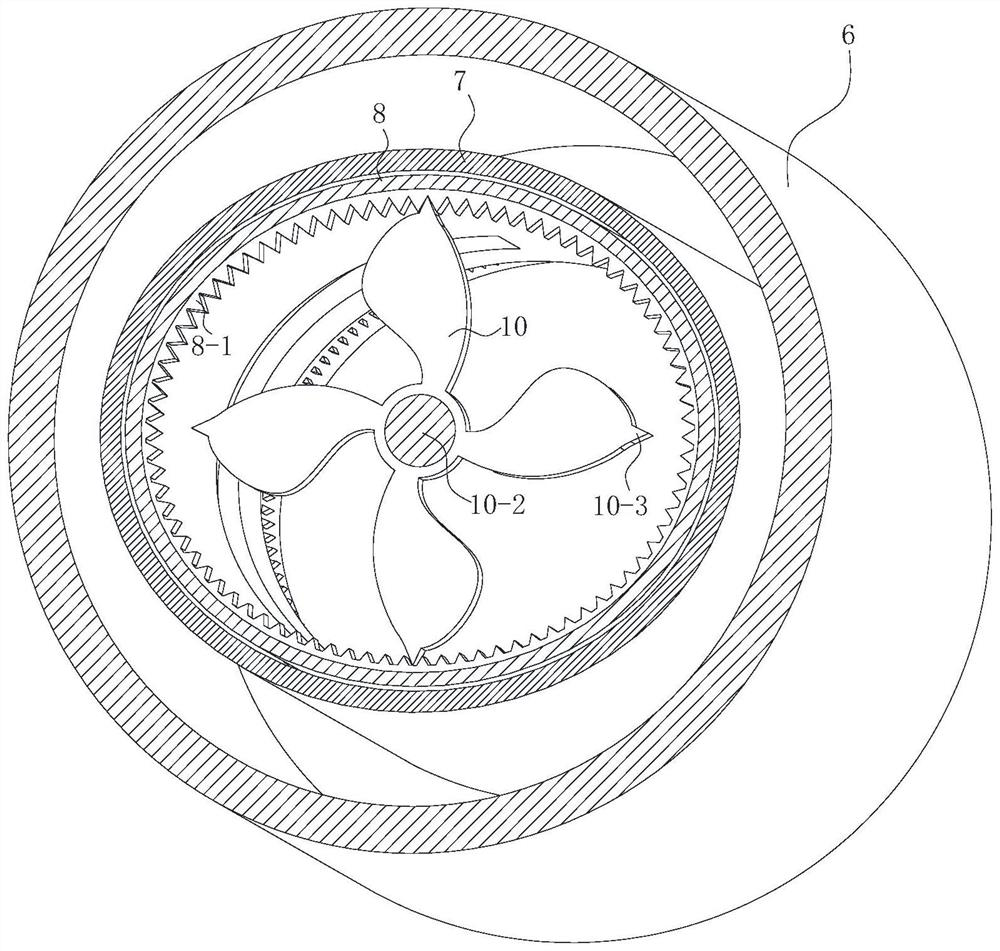

Autoclaved aerated concrete block water content control device

ActiveCN108972856AJet evenlyConducive to direct contactCeramic shaping apparatusGear wheelEngineering

The invention discloses an autoclaved aerated concrete block water content control device which comprises an autoclaving bin. A base is arranged at the lower portion of the interior of the autoclavingbin, and a steel rail is installed above the base. By means of the autoclaved aerated concrete block water content control device, a first bevel gear is driven through a rotating motor to rotate so as to drive a second bevel gear to rotate, in addition, the second bevel gear drives a rotating shaft to rotate so that wheels can roll in wheel rails, then a guide pipe can swing and move along the wheel rails and are matched with spraying heads which are evenly distributed in the ring-shaped guide pipe to spray gas to concrete blocks, autoclaving and aerating are evenly conducted on the concreteblocks conveniently, and pits which are likely to happen in the surfaces of the concrete blocks due to gas sprayed by the spraying gas are avoided. In addition, an electric push rod is used for pushing a humidity sensor to enter a through hole and be inserted into the concrete blocks to conduct humidity detection, and therefore the humidity sensor can directly make contact with the concrete blocksconveniently, and water content detection can be accurately conducted on the concrete blocks conveniently.

Owner:HENGYANG HENGYU LIGHTWEIGHT INSULATION MATERIAL CO LTD

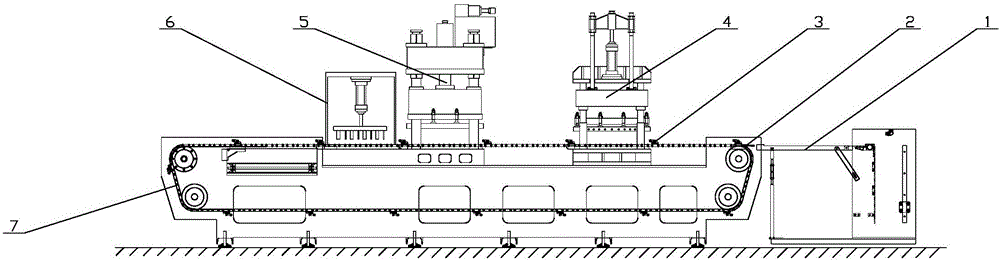

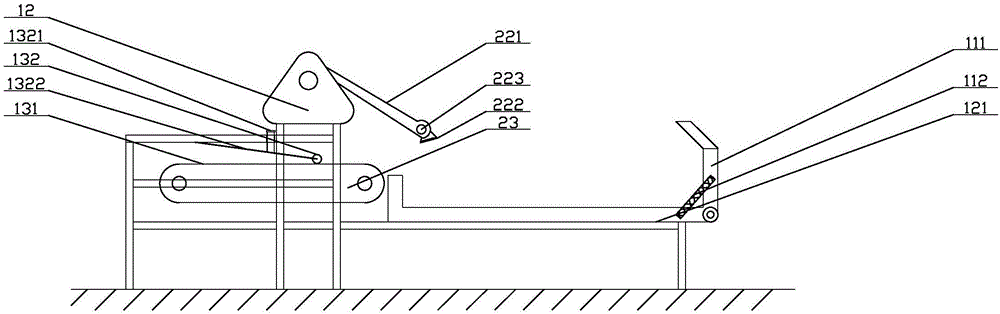

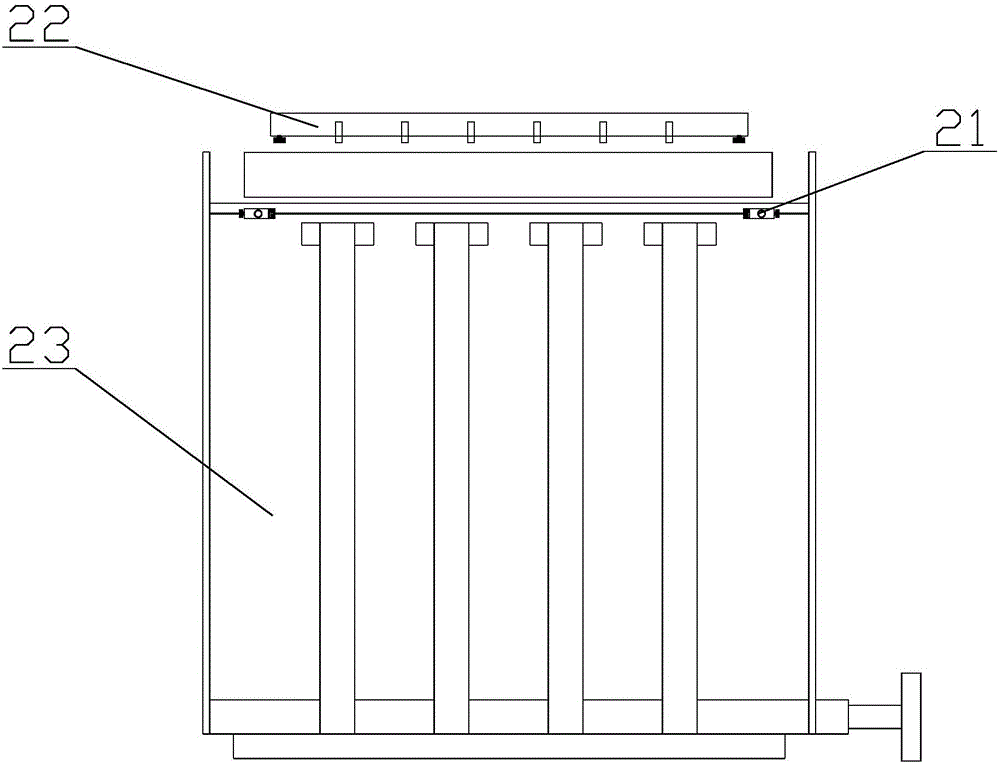

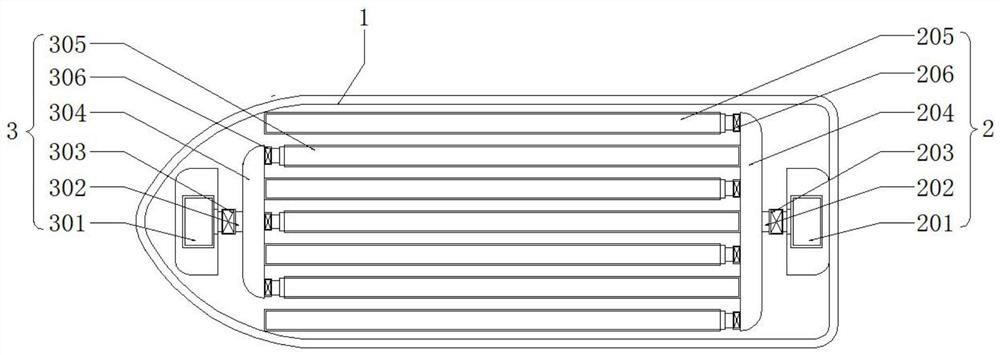

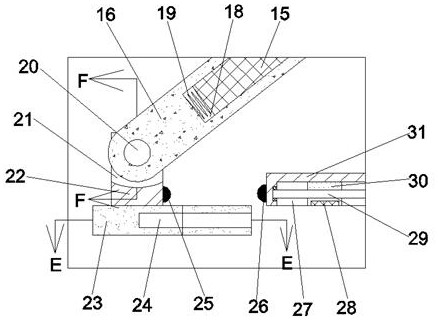

Full-automatic soft-line sectional die-cutting machine and operating method thereof

InactiveCN106739137ASave human effortReduce labor intensityPaper-makingBox making operationsMechanical engineeringEngineering

The invention relates to a packing box processing device, in particular to a full-automatic soft-line sectional die-cutting machine and an operating method thereof. The full-automatic soft-line sectional die-cutting machine is simple in structure and is characterized in that two procedures of indentation and slitter edge removal of a plastic sheet are finished during one-time clamping to realize high-precision processing and high processing efficiency. The full-automatic soft-line sectional die-cutting machine comprises a rack and a controller, wherein a closed-cycle chain conveyor is arranged on the rack, a plurality of clamping and conveying mechanisms are uniformly distributed in the conveying direction of the chain conveyor, and a support wheel part at the head ends of the rack and the chain conveyor is a feeding end; and adjustment holes are formed in the two ends of stiffeners, adjustable bolts are arranged in the adjustment holes, and a stop block is arranged on the rear side of each adjustment hole. The full-automatic soft-line sectional die-cutting machine has the advantages that dents and cut edges are integrally formed, the borders of the cut edges are smooth, the dents are equal in depth, the processing efficiency is high and the structure is simple.

Owner:YANGZHOU SU PACK NEW MATERIAL TECH CO LTD

Circuit board cleaning and dust removal equipment

The invention discloses circuit board cleaning and dust removal equipment. The equipment comprises a connecting block, a rotating wheel is rotatably connected with the interior of the connecting block, the rotating wheel is internally and fixedly provided with a driving motor, the lower end of the driving motor is in power connection with an air injection mechanism, the air injection mechanism comprises a rotating shaft and a driving shaft, and the rotating shaft and the driving shaft are in power connection with the lower end of the driving motor. A rotating rod is fixedly connected to the lower end of the rotating shaft, the rotating rod is internally provided with a guide sliding groove with a downward opening, and a sliding block is slidably arranged in the guide sliding groove. According to the equipment, a circuit board can be automatically subjected to air jet cleaning and dust removal, manual operation steps are few, the automation degree is improved, and the cleaning and dustremoval efficiency is improved; besides, an air injection pump can spray air uniformly on the surface of the circuit board, and the cleaning effect of the circuit board is improved; and in the cleaning process, the air injection pump cannot touch electrical components on the circuit board, so that damage to the circuit board is avoided.

Owner:山东天益通元电子科技有限公司

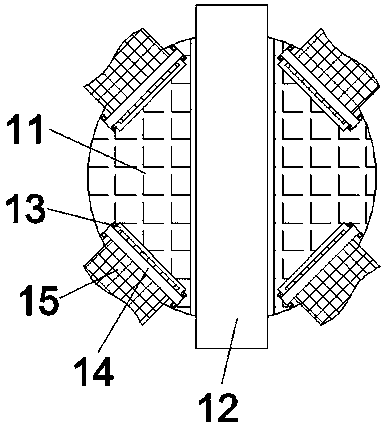

Pulse pneumatic injector

The invention relates to a pulse air pressure type fire water gun, comprising an air storage tank, a liquid storage tank, and a multi-way combination valve arranged at the air inlet of the liquid storage tank for controlling the communication between the air storage tank and the liquid storage tank (3); wherein the air storage tank is an annular cylindrical structure arranged around the liquid storage tank and the multi-way combination valve (3). The injector has a smooth high-pressure gas injection channel, thereby improving the injection kinetic energy and impact force of the sprayed water mist, and can adjust the air pressure of the injected gas according to the needs of the operation.

Owner:魏厚瑗 +1

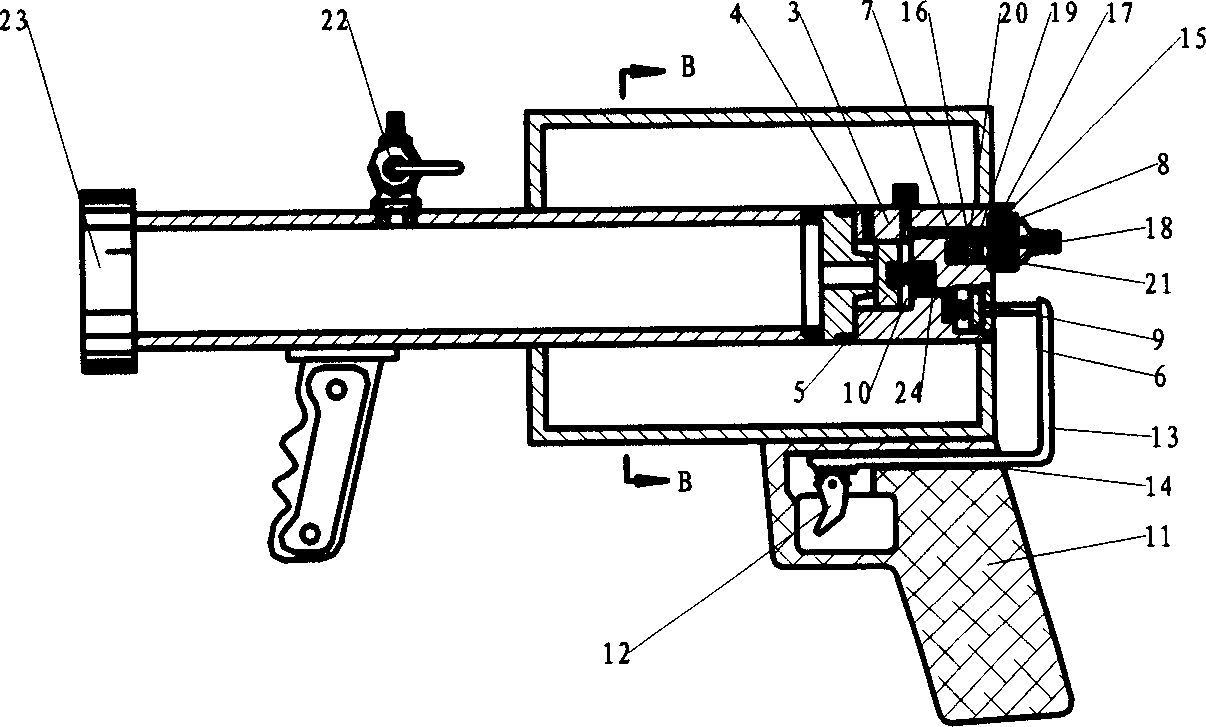

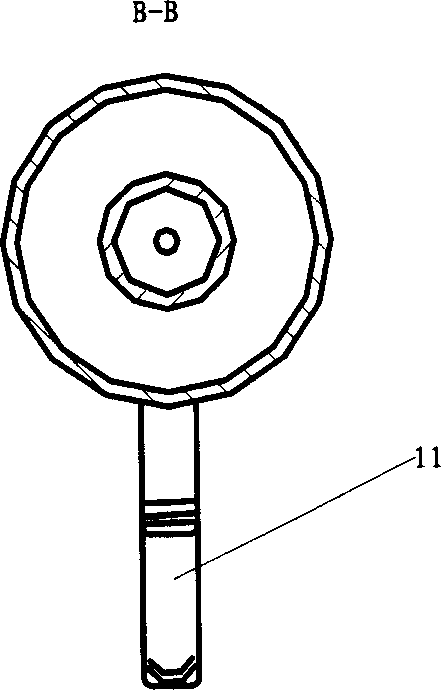

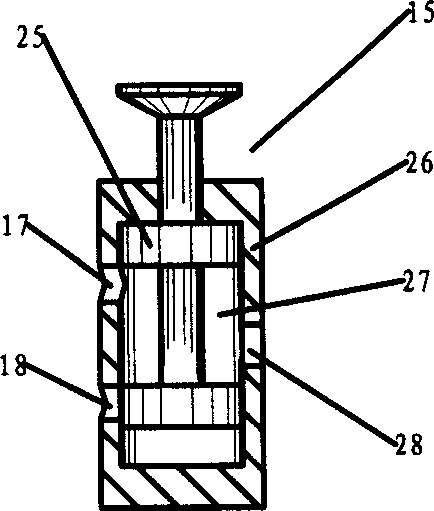

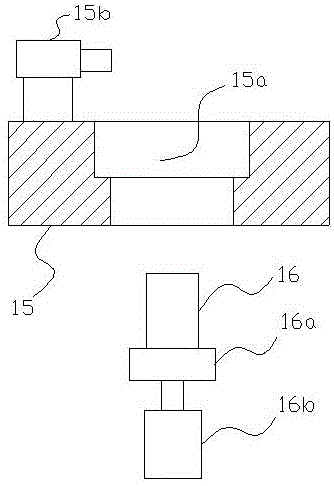

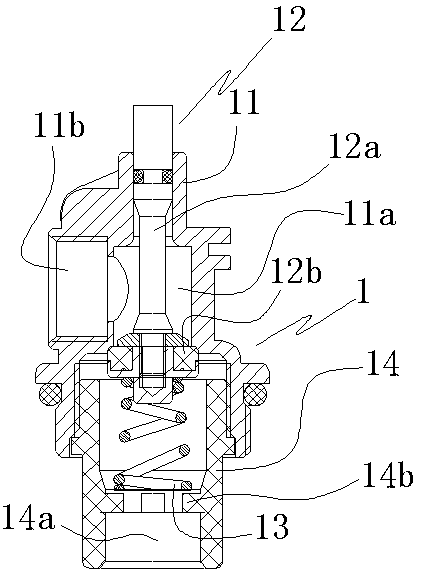

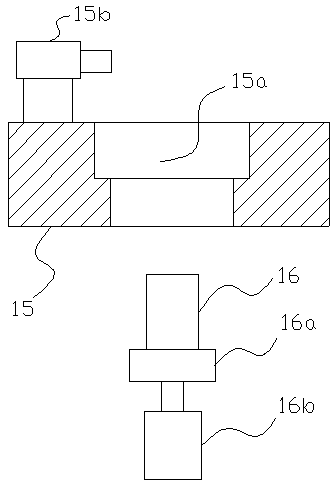

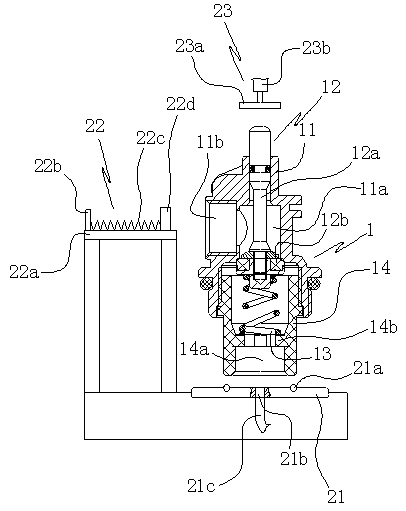

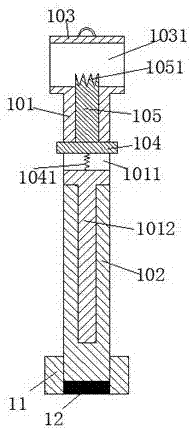

Ultra-fine dry powder fire extinguisher structure and valve mounting system

ActiveCN106621132ASimple structureEasy to installFire rescueMetal-working hand toolsEngineeringFire extinguisher

The invention provides an ultra-fine dry powder fire extinguisher structure and a valve mounting system, belongs to the technical field of fire extinguishers, relates to a fire extinguisher valve, and solves the problems of poor valve sealing effect, inconvenience in use and operation, unsmooth injection and difficult disassembly in the prior art. The ultra-fine dry powder fire extinguisher structure comprises a tank body and a valve, wherein the valve comprises an upper valve seat, a spool assembly, a reset spring and a lower valve seat; the valve mounting system comprises an assembly table; big-end-up stepped holes allowing the upper valve seat to be placed are formed in the assembly table; an insertion rod which can be inserted into an air outlet of the valve is arranged on the assembly table; a rotary head corresponding to the passage in the pipe of the lower valve seat is arranged below the assembly table; the rotary head is provided with a square end matched with a square cavity of the passage in the pipe of the lower valve seat; and the rotary head is controlled by a telescopic mechanism to expand and contract vertically. The ultra-fine dry powder fire extinguisher structure disclosed by the invention is simple in the structure, good in sealing performance, easy to operate and quick in spraying; and the valve mounting system disclosed by the invention can be used for quickly assembling the valve, and is simple in structure and convenient to operate.

Owner:ZHEJIANG ORIENTX FIRE SAFETY EQUIP

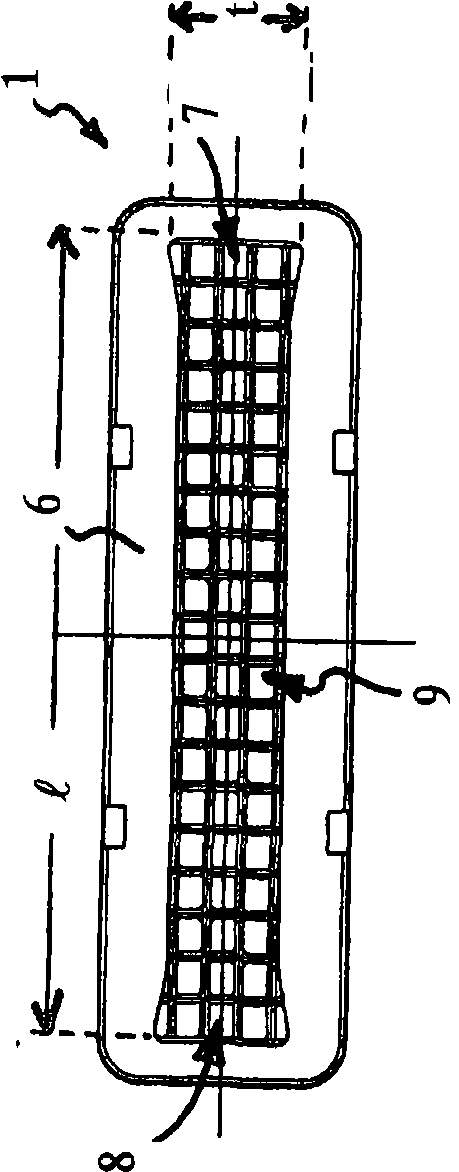

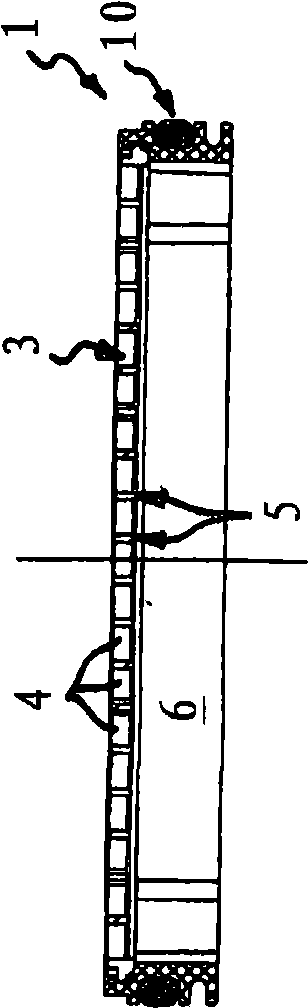

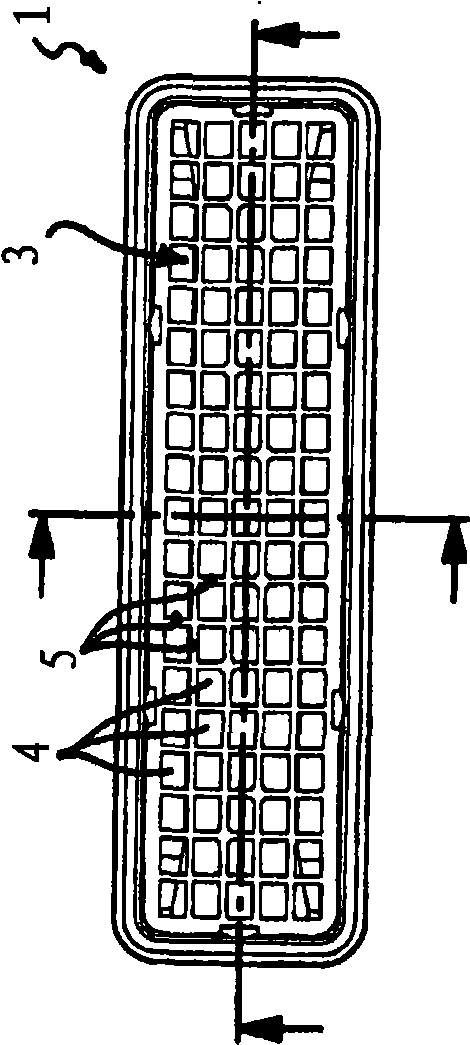

Jet former

The former (1) has a homogenizing device with a set of passage holes that are limited by a flow guiding wall, where the former has a larger stream width compared to stream depth (t) for producing a flat water flow volume. A flow guide (6) is provided upstream or downstream and narrows in a partial area in a flow direction. The flow guide has edge areas (7, 8) with a larger flow cross section relative to a longitudinal middle area (9), where the edge areas extend in both sides of the guide in a longitudinally extending manner.

Owner:NEOPERL

Valve installation system for superfine dry powder fire extinguisher structure

ActiveCN106621132BSimple structureEasy to installFire rescueMetal-working hand toolsEngineeringUltra fine

The invention provides an ultra-fine dry powder fire extinguisher structure and a valve mounting system, belongs to the technical field of fire extinguishers, relates to a fire extinguisher valve, and solves the problems of poor valve sealing effect, inconvenience in use and operation, unsmooth injection and difficult disassembly in the prior art. The ultra-fine dry powder fire extinguisher structure comprises a tank body and a valve, wherein the valve comprises an upper valve seat, a spool assembly, a reset spring and a lower valve seat; the valve mounting system comprises an assembly table; big-end-up stepped holes allowing the upper valve seat to be placed are formed in the assembly table; an insertion rod which can be inserted into an air outlet of the valve is arranged on the assembly table; a rotary head corresponding to the passage in the pipe of the lower valve seat is arranged below the assembly table; the rotary head is provided with a square end matched with a square cavity of the passage in the pipe of the lower valve seat; and the rotary head is controlled by a telescopic mechanism to expand and contract vertically. The ultra-fine dry powder fire extinguisher structure disclosed by the invention is simple in the structure, good in sealing performance, easy to operate and quick in spraying; and the valve mounting system disclosed by the invention can be used for quickly assembling the valve, and is simple in structure and convenient to operate.

Owner:ZHEJIANG ORIENTX FIRE SAFETY EQUIP

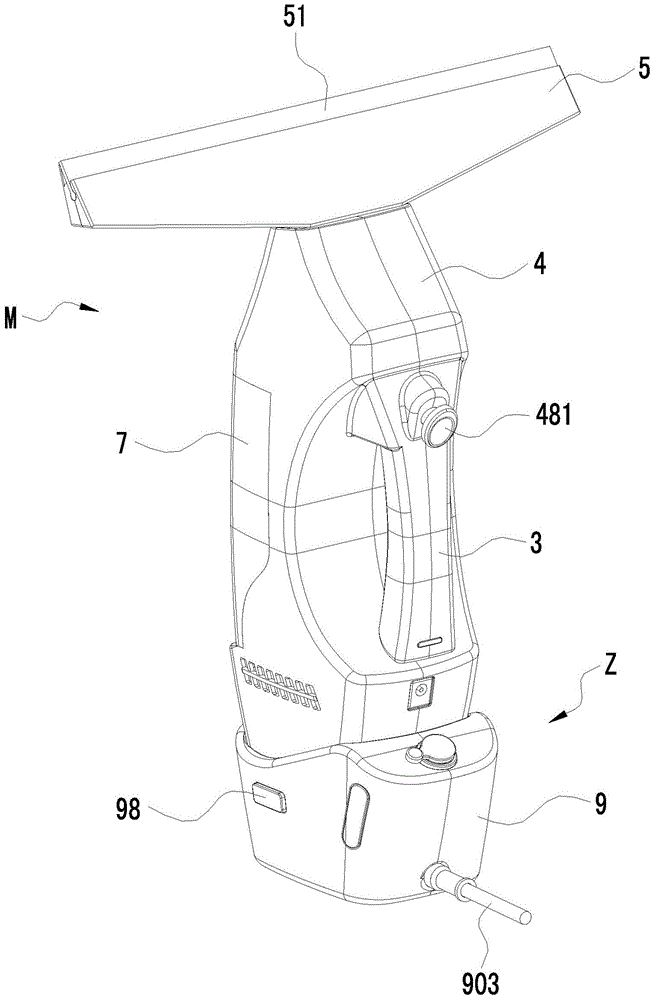

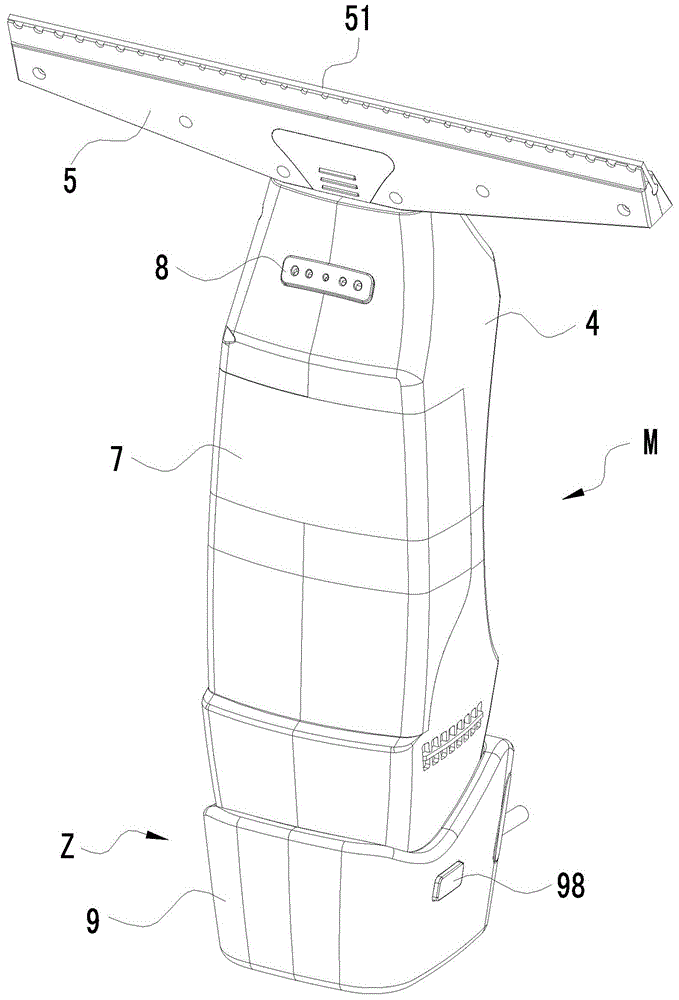

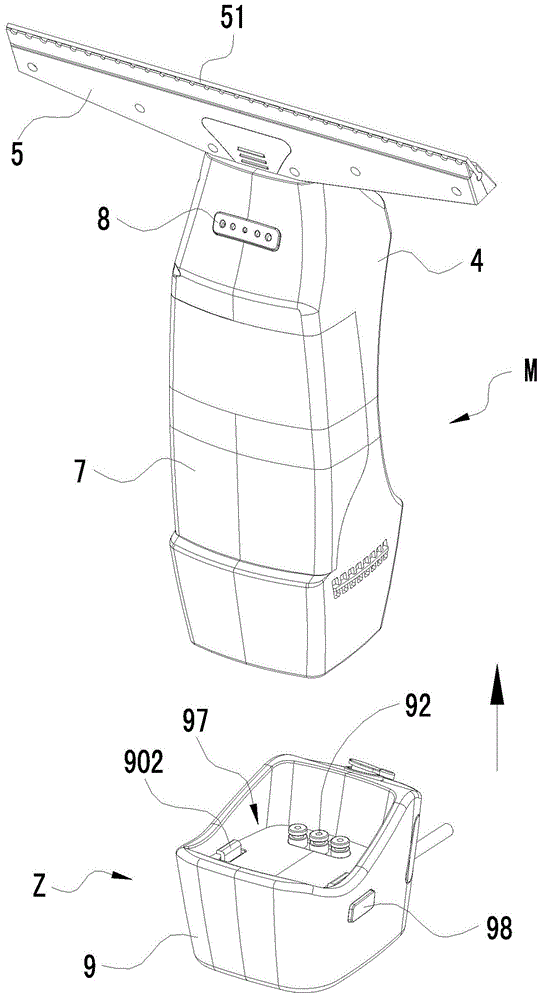

Spray nozzle of window scraping device

InactiveCN104127155AExpand the spraying areaExtended jet rangeWindow cleanersSpray nozzlePulp and paper industry

The invention relates to a device for cleaning the surface of glass, in particular to a spray nozzle of a window scraping device. The spray nozzle comprises a spray nozzle shell. The spray nozzle shell is provided with a steam inlet pipe allowing steam to be injected, a steam chamber and two or more steam spray holes. The steam inlet pipe and the steam spray holes are all communicated with the steam chamber. Steam entering the steam chamber through the steam inlet pipe is sprayed out through the steam spray holes. Steam is simultaneously sprayed out through the steam spray holes, and therefore the spray area of the steam is enlarged, the steam spray range of the surface of the glass can be widened through the spray nozzle, steam can be uniformly sprayed to the surface of the glass, the cleaning effect is better, cleaning is comprehensive, and a cleaner effect is achieved; the arrangement direction of the steam spray holes is parallel to the length direction of a scraping strip, and therefore in the cleaning process, due to the fact that the arrangement direction of all the steam spray holes is parallel to the length direction of the scraping strip, the steam spray holes are used in cooperation with the long-strip-shaped flexible scraping strip for spraying steam to most of the area swept by the long-strip-shaped flexible scraping strip, the cleaning effect is better, cleaning is comprehensive, and the better cleaning effect is achieved.

Owner:ZHONGSHAN JINSHUN HOUSEHOLD WARES +1

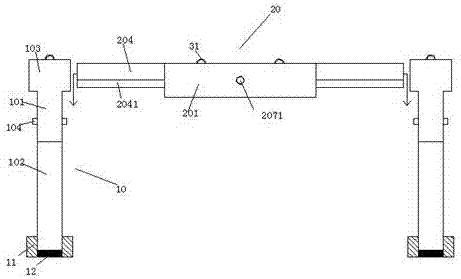

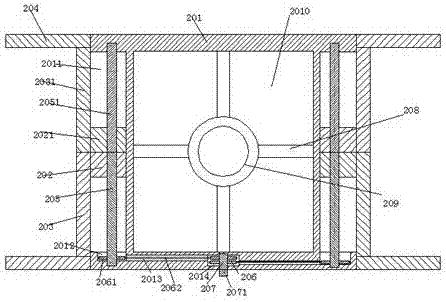

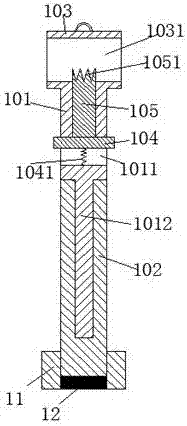

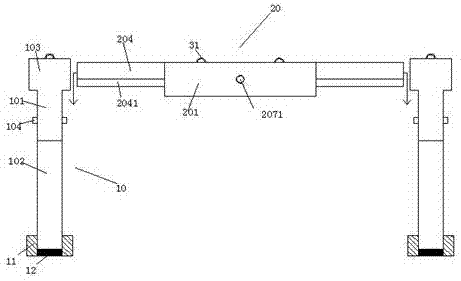

Bridge equipment

InactiveCN107013055AAdjustable footprintAvoid center of gravity shiftSpecial buildingBuilding constructionsMechanical engineering

Owner:陈光才

Novel full-automatic intelligent ironer

InactiveCN106894219AEven ironing effectImproved garment stylingIroning apparatusTextiles and paperProcess engineeringEngineering

The invention discloses a novel full-automatic intelligent ironer. Temperature and time are set, different ironing modes are selected according to different clothes materials, then an operation panel is started through one key, a steam controller controls a steam generator to work, and generated steam is conveyed to a steam moving brush; then clothes are ironed and shaped, the angles of the clothes are freely adjusted through a rotator, and 360-degree rotary ironing is ensured. After ironing is completed, a heat radiation device of the rotator is started, a nano resin hollow pipe used for the steam moving brush is even in spraying, and the clothes can be evenly in contact with the steam. A fully sealed structure is adopted, the intelligent operation process of the automatic ironer is achieved, the ironing effects of all the positions of the clothes tend to be more even, and the clothes finishing and shaping effect is obviously improved. Meanwhile, the time of manual operation is greatly shortened, the labor cost is greatly reduced, and production efficiency is improved.

Owner:JINING POLYTECHNIC

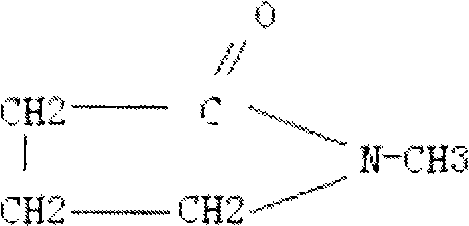

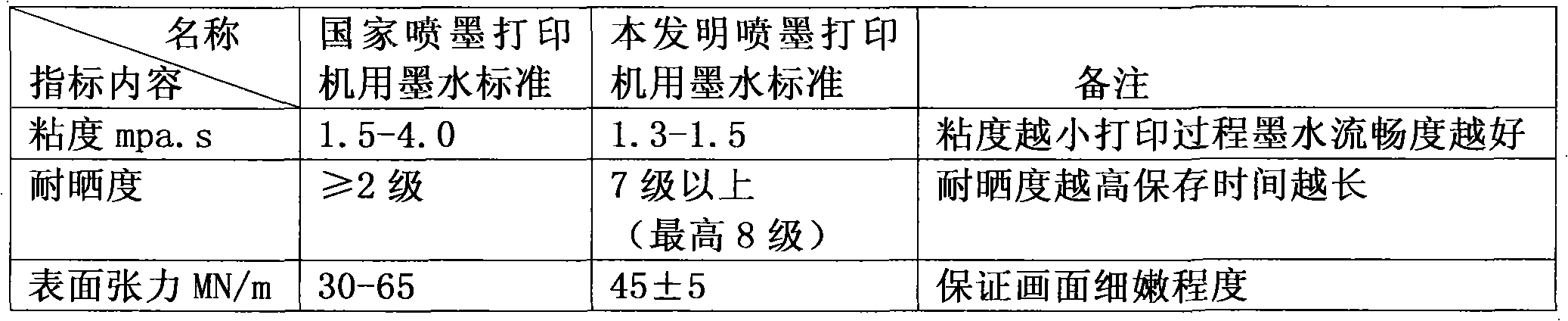

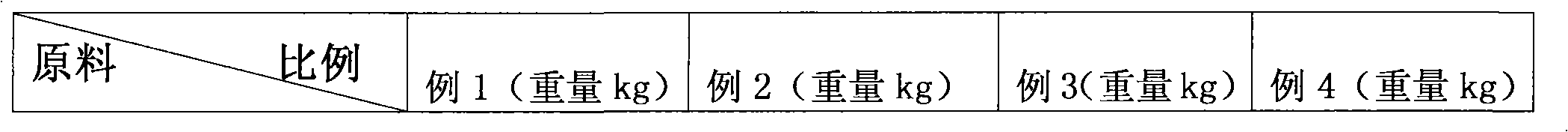

Jet ink for digital print and preparation method thereof

The invention relates to digital printing inkjet ink, which is prepared by the following materials: pigment (red / yellow / blue / black), sodium dodecyl benzene sulfonate, N n-dimethylformamide, 1.2-propylene glycol, polyvinylpyrrolidone K30, deionized water. The invention relates to a preparation method of the digital printing inkjet ink, which includes the following steps: the pigments, sodium dodecyl benzene sulfonate and 1.2-propylene glycol are respectively weighed, and put in container A, stirred, and mixed evenly; deionized water and polyvinylpyrrolidone K30 are respectively weighed, and deionized water and polyvinylpyrrolidone K30 accounting for 10 percent of the total weight are put in container B, and heated and stirred until the two materials are completely dissolved, and then are put in the container A, and stirred and mixed evenly; N n-dimethylformamide is weighed, and the weighed N n-dimethylformamide and the residual deionized water are put in the container A, and are stirred, placed statically and filtered to produce the finished product. The digital printing inkjet ink applies to different models of machines, and is material saving and convenient; the colors are rich, beautiful and stable, and are strongly coated without plugging; the spraying is mellifluent; the character strokes in pictures do not proliferate, the paper is not easily wrinkled, the fastness is high, the product is ultraviolet radiation resistant, and the images can be reserved for fifty years without fading.

Owner:曾观涛 +2

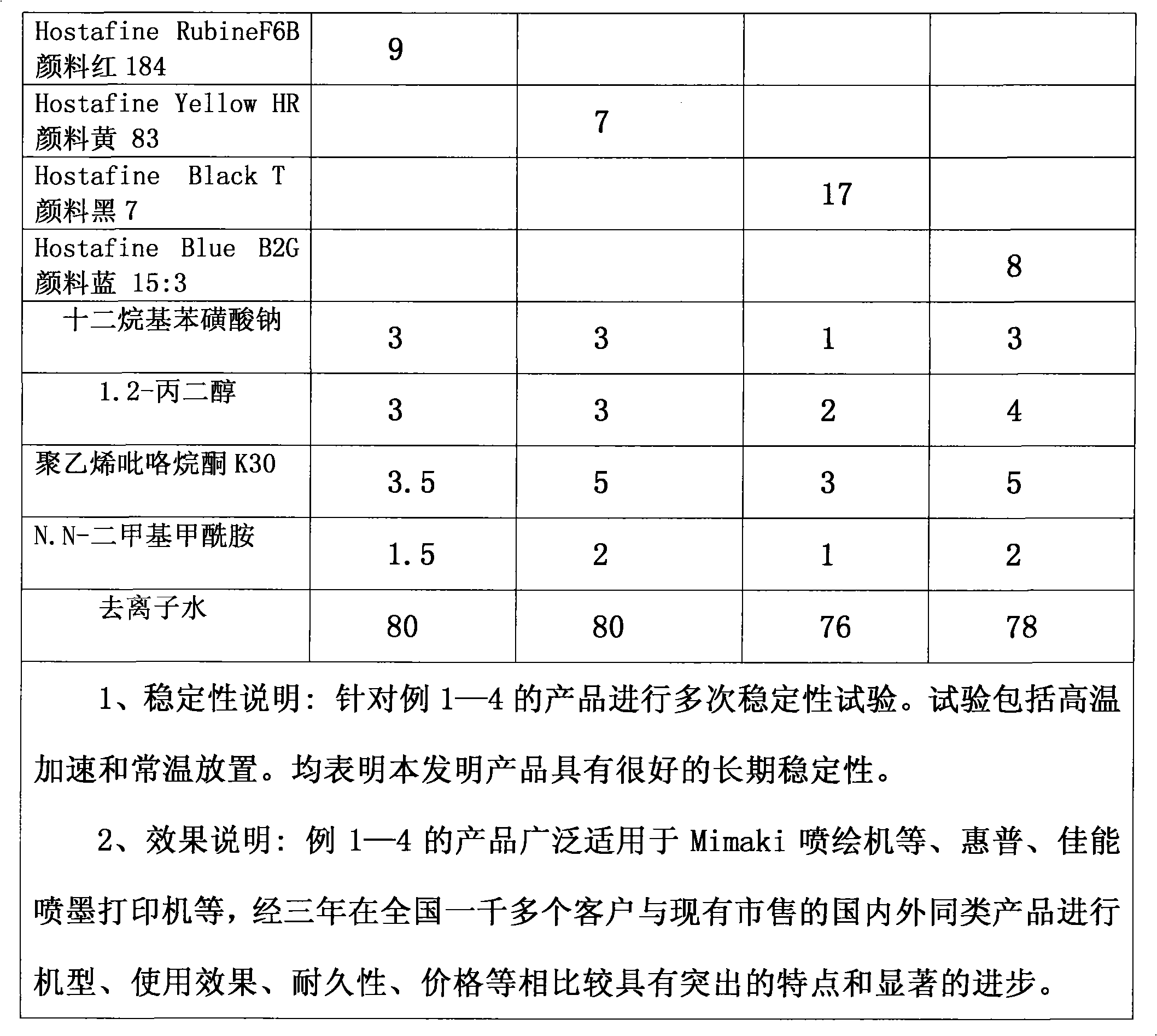

Paint spraying gun

The invention discloses a paint spraying gun. The paint spraying gun comprises a gun body, a nozzle and a paint tank, wherein the gun body comprises a spraying pipe and a handle; one end of the spraying pipe is connected with the handle, and the other end of the spraying pipe is movably connected with the nozzle through a connecting piece; the nozzle is a hollow cavity; a connecting pipe is arranged on the spraying pipe, and is movably connected with the paint tank; a first stirring piece is arranged in the spraying pipe near the nozzle; a second stirring piece is arranged in the nozzle; coating layers are arranged on the inner walls of the spraying pipe and the nozzle; the coating layers comprise anti-bonding layers, insulation layers and protection layers; the protection layers are bonded with the inner walls of the spraying pipe and the nozzle; and the anti-bonding layers are bonded with the protection layers through the insulation layers. The paint spraying gun is provided with thestirring pieces and the coating layers on the spraying pipe and the nozzle, so that the paint viscosity is reduced, and the problem of unsmooth painting caused by blockage of the spraying gun is effectively solved.

Owner:湖南太子化工涂料有限公司

Garden seedling spraying device

ActiveCN108207896BEasy to useJet evenlyRotary stirring mixersTransportation and packagingAgricultural engineeringMechanical engineering

Owner:福建省鼎贤市政园林工程有限公司

A power distribution box with high heat dissipation performance

ActiveCN107332134BImprove cooling effectSolve uneven heat dissipationSubstation/switching arrangement cooling/ventilationMechanical energy handlingEngineeringHigh heat

Disclosed is a power distribution box with high heat dissipation performance. The power distribution box comprises a base, a box body is fixedly connected at the top of the base, a partition board is fixedly connected between the two opposite sides of the cavity inside the box body, the right side of the bottom of the cavity in the box body is fixedly connected with a transmission device, the top of the transmission device is provided with a support rod in a penetrating manner, the top end of the support rod penetrates the partition board and extends to the top of the partition board, the left side of the bottom of the cavity in the box body is fixedly connected with a first blower, and an exhaust of the first blower runs through the left side of the box body and extends to the outside of the box body. The air outlet of the first blower is connected with a cooler, and the bottom of the cooler is fixedly connected with the bottom of the cavity of the box body. The present invention relates to the technical field of machinery. The power distribution box with high heat dissipation performance solves the problem of uneven distribution of heat in the conventional distribution box, reduces the frequency of inspection and replacement of the electrical components, prevents the electrical components from being damaged due to overheating, and indirectly improves the working electrical components' efficiency.

Owner:SHANGHAI ZHEZHONG ELECTRIC

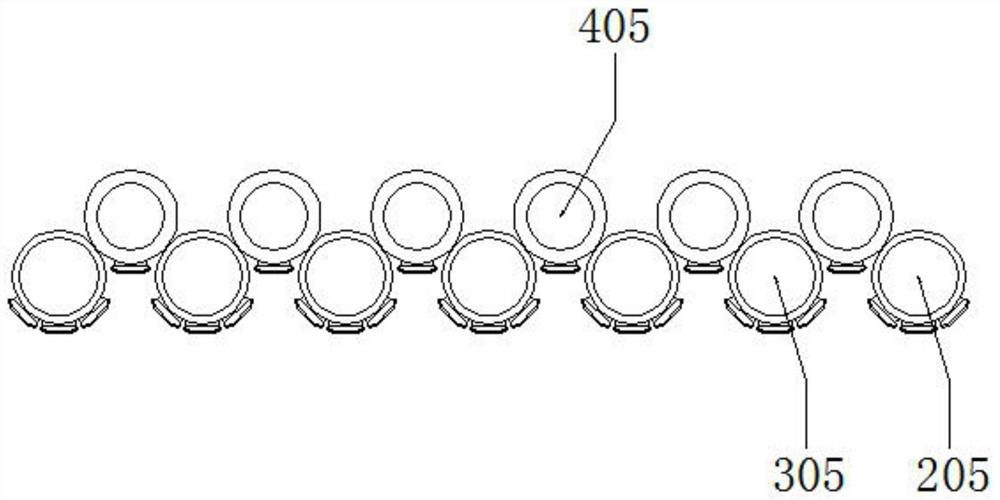

Degassing sheet for gas-jet refining molten metal and preparation method thereof

The invention relates to a degassing sheet for jet refining of molten metal and a preparation method of the degassing sheet. The degassing sheet comprises the following components in percentage by mass: 50%-60% of mullite, 10%-20% of white corundum, 20%-30% of alumina micro powder and 2%-5% of clay, wherein all components are combined together by adopting a gel binding agent; the amount of the gel binding agent is 4%-5% of total mass of the components. The preparation method comprises the following steps: sequentially burdening, mixing raw materials, and then pressing and molding on a 2-4MPa of vibration molding machine; and baking at 100-140 DEG C, and then firing into a green brick in a shuttle kiln. The preparation method disclosed by the invention is simple; the prepared degassing sheet has the advantages of small jet aperture, jet uniformity, long service life, small resistance, and relatively low production cost, and is simple and convenient to use; nonferrous metal is not easy to ooze; and the working area and the ventilation efficiency are greater than those of common air bricks.

Owner:江苏苏嘉集团新材料有限公司

A kind of cooling and ventilation equipment for box-type substation and using method thereof

ActiveCN112260112BReduce the temperatureAvoid inhalationSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsDust controlEngineering

The invention discloses a method for using cooling and ventilation equipment for a box-type substation. A dust removal assembly is fixedly installed on the inner wall of the top side of the cooling box, and a turbo fan located on one side of the cooling box is fixedly installed on the top of the base. It extends into the cooling box and communicates with the dust removal assembly, and a fixing plate is fixedly installed in the cooling box. The invention can realize the cooling and drying of the gas entering into the box of the substation, and can realize uniform jetting after the gas is transported into the box of the substation, so as to realize uniform and rapid cooling of the box of the substation, thus avoiding the need for the box of the substation The temperature in the body is too high, so it has good practicality.

Owner:山东德普电力有限公司

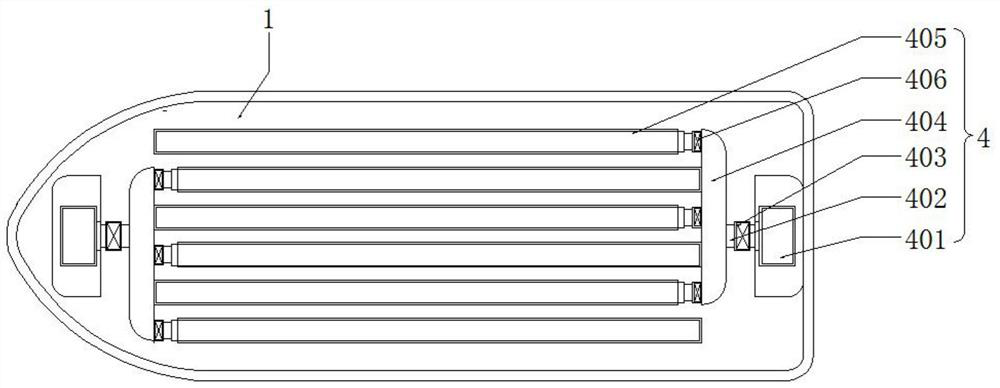

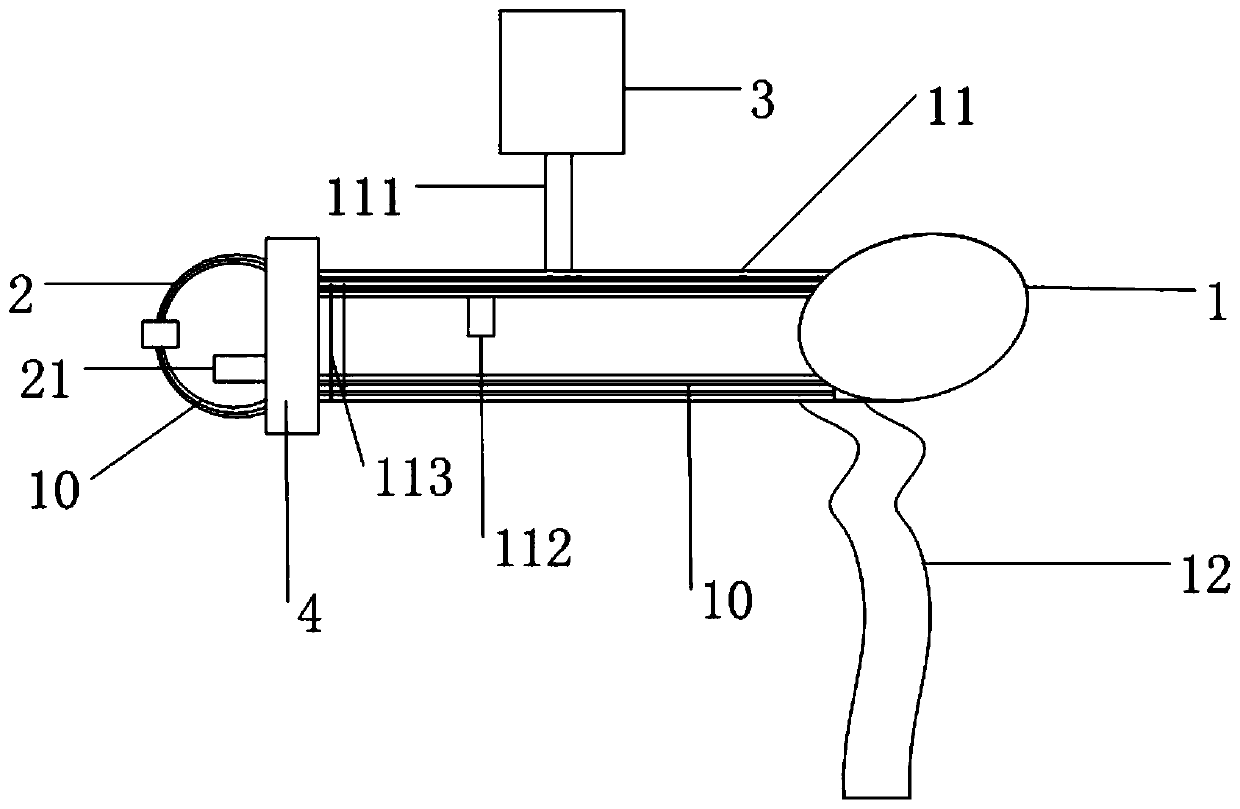

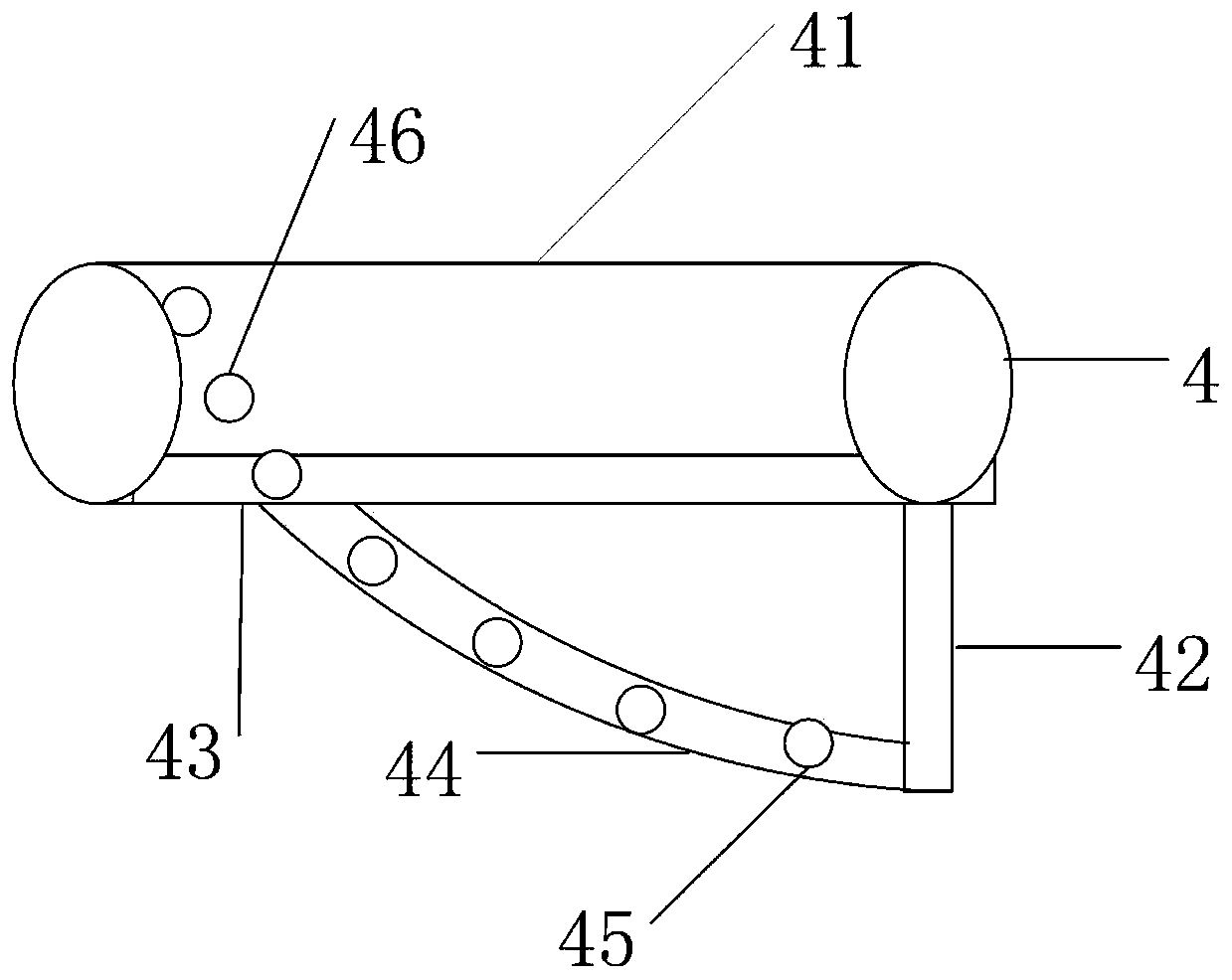

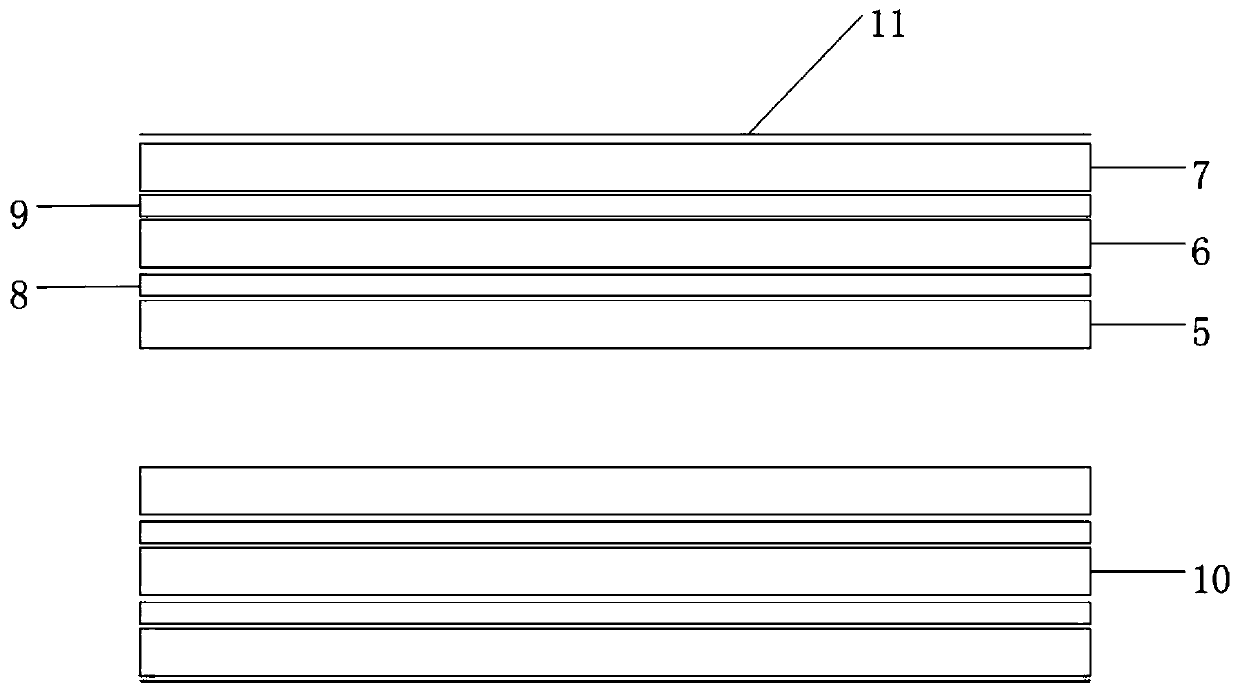

Intelligent ship air curtain resistance reducing and energy saving device

ActiveCN113978604AReduce sailing resistanceIncrease airflowNon-rotating vibration suppressionWatercraft hull designAir pumpStern

The invention discloses an intelligent ship air curtain resistance reducing and energy saving device, and relates to the technical field of ship air curtain resistance reduction, the intelligent ship air curtain resistance reducing and energy saving device comprises a ship, upper layer air curtain assemblies and a jet head, a ship tail air curtain assembly is installed behind the bottom of the ship, and a ship head air curtain assembly is installed in front of the bottom of the ship; the upper layer air curtain assemblies are arranged on the upper sides of the ship tail air curtain assembly and the ship head air curtain assembly, the ship tail air curtain assembly comprises a ship tail air pump, a ship tail air injection pipe, a ship tail air valve, a ship tail pressure stabilizing cavity, a ship tail air conveying pipe and a ship tail secondary valve, and one side of the ship tail air pump is connected with the ship tail air injection pipe. According to the intelligent ship air curtain resistance reducing and energy-saving device, the upper-layer air conveying pipe is flatly laid above the ship tail air conveying pipe and the ship head air conveying pipe, the airflow strength can be enhanced by matching with the ship tail air conveying pipe and the ship head air conveying pipe, and the sailing resistance of a ship can be reduced; and the lower parts of the ship tail air conveying pipe and the ship head air conveying pipe can be positioned and fixed with a shockproof effect.

Owner:ZHEJIANG OCEAN UNIV

a paint spray gun

Owner:湖南太子化工涂料有限公司

A circuit board cleaning and dust removal equipment

A circuit board cleaning and dust removal device disclosed by the present invention includes a connecting block, a rotating wheel is rotatably connected in the connecting block, a driving motor is fixed in the rotating wheel, and an air injection mechanism is connected to the lower end of the driving motor. The air injection mechanism includes a rotating shaft and a driving shaft that are powered connected to the lower end of the driving motor. The inner slide is provided with a slider, and the present invention can automatically clean and remove dust from the circuit board with less manual operation steps, improve the degree of automation, and further improve the efficiency of cleaning and dust removal, and the air jet pump can evenly spray air on the surface of the circuit board, thereby improving The cleaning effect of the circuit board, the air jet pump will not touch the electrical components on the circuit board during the cleaning process, thereby avoiding damage to the circuit board.

Owner:山东天益通元电子科技有限公司

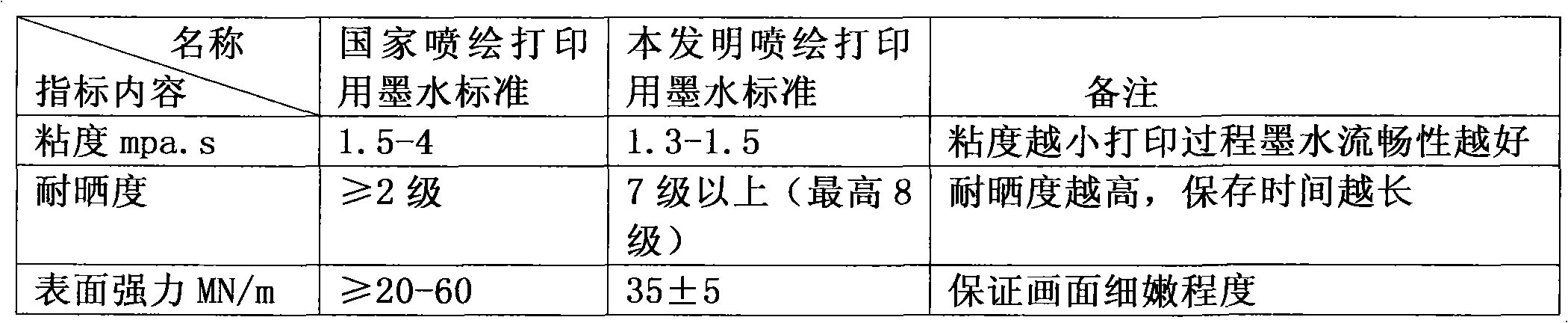

Digital jet painting inking ink and preparation method thereof

The invention relates to digital jet painting inking ink. The digital jet painting inking ink is prepared from the following raw materials: pigments (red / yellow / blue / black), carbolic acid, glycerin, ethylene glycol, triethanolamine, isopropyl alcohol and deionized water. A preparation method for the digital jet painting inking ink comprises the following steps: respectively weighing the glycerin,the ethylene glycol and the pigments of the raw materials, and placing the glycerin, the ethylene glycol and the pigments in a scaled container; respectively weighing the deionized water and the carbolic acid of the raw materials, placing 10 weight percent of the deionized water and the carbolic acid in the container, heating and stirring the mixture in the container until the carbolic acid is fully dissolved, and then placing the carbolic acid dissolved in the deionized water into the scaled container for stirring and even blending; and respectively weighing the triethanolamine and the isopropyl alcohol of the raw materials, placing the triethanolamine, the isopropyl alcohol and the rest of the deionized water in the scaled container, and obtaining a finished product after stirring, standby, filtering and packaging. The digital jet painting inking ink is suitable for different machine models, saves materials, and has convenience, quickness, abundant and flamboyant colors, high stability, good dyeing power, tiny insolubles, no blockage, smooth jet, no dispersed picture words, no crumpled paper, high fastness, and ultraviolet radiation resistance. A picture has light fastness for as long as fifty years.

Owner:BEIJING PEIHONG WANGZHI TECH

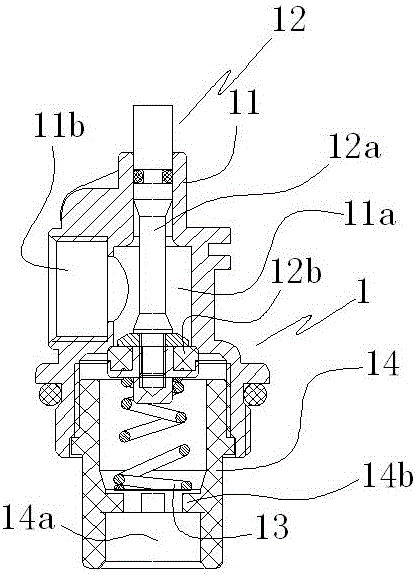

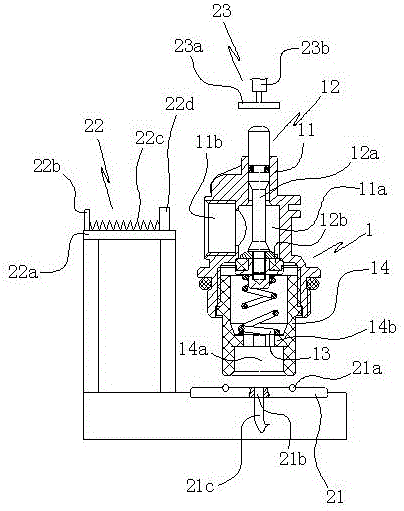

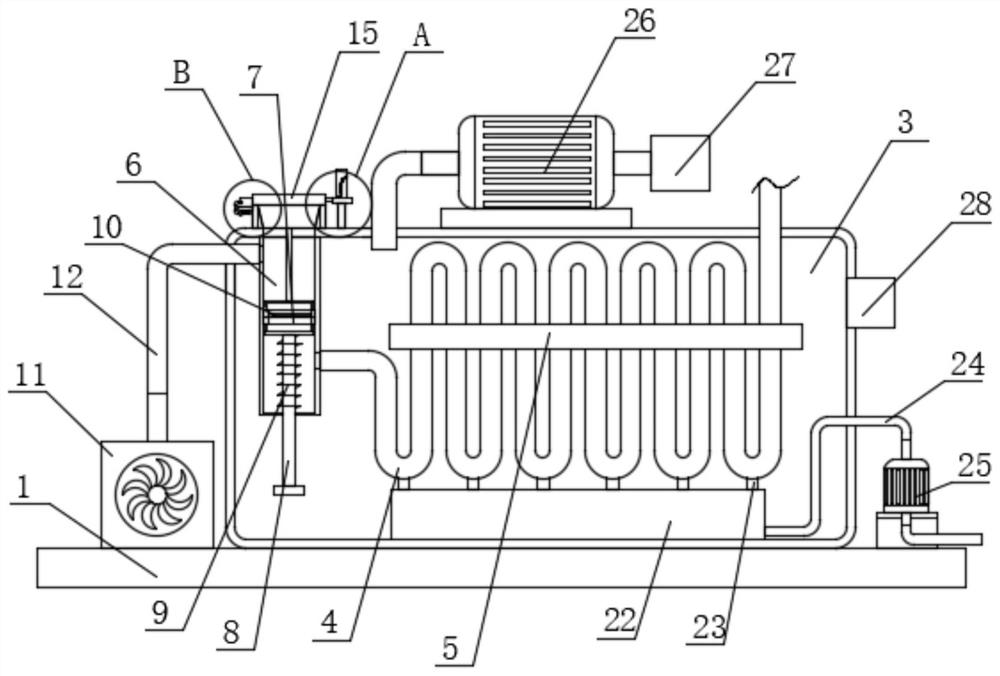

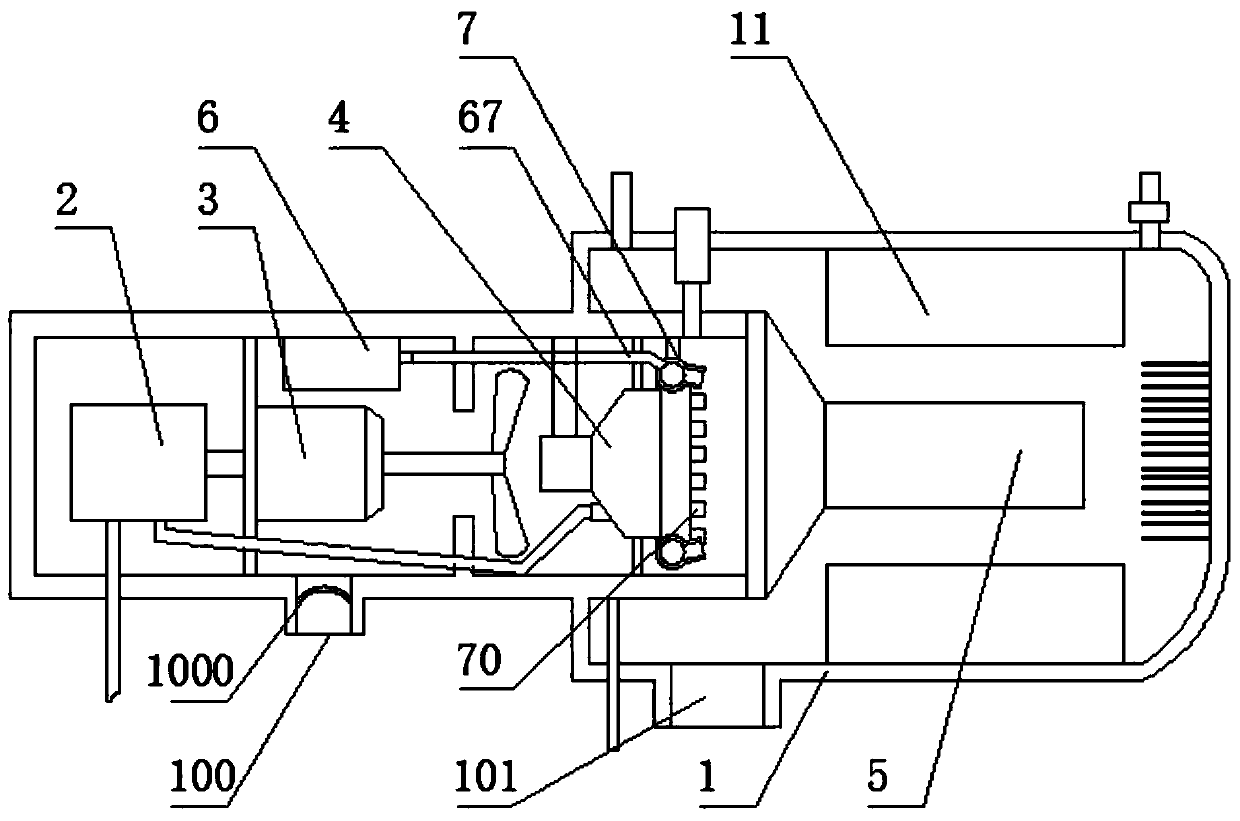

Heating module assembly of parking heater

The invention discloses a heating module assembly of a parking heater. The module comprises a housing, wherein an oil pump, a motor and an oil injector are arranged on the front side of the housing; combustion-supporting fan blades are arranged at a driving shaft at the rear end of the motor; a micro blowing pump is fixed on the inner side surface of the upper end of the housing; a circular tube is fixed on the inner side surface, at a position of the oil injector, of the rear side of the housing by connectors; an air outlet in the micro blowing pump is connected to the inner side surface of one end of the circular tube via an air guide tube; and injection convex ports are formed in the outer surface of the other end of the circular tube. The combustion-supporting fan blades are driven bythe own motor to rotate and blow air to support combustion, the micro blowing pump is added to blow the air, the air is blown out through the injection ports in outside of the circular tube at a portof the oil injector, air flow is more concentrated, oil mist can be quickly boosted, and the strong air flow can blow away the oil mist twice, and the atomization degree is increased, so that full combustion performance is improved.

Owner:温州富力电气有限公司

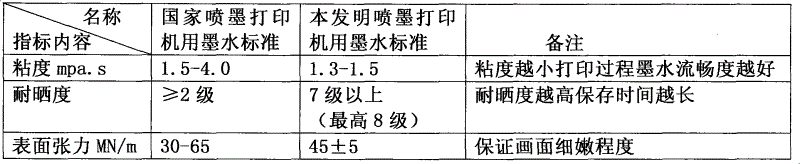

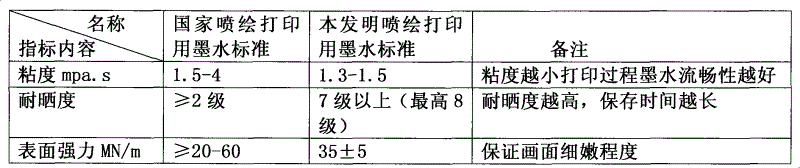

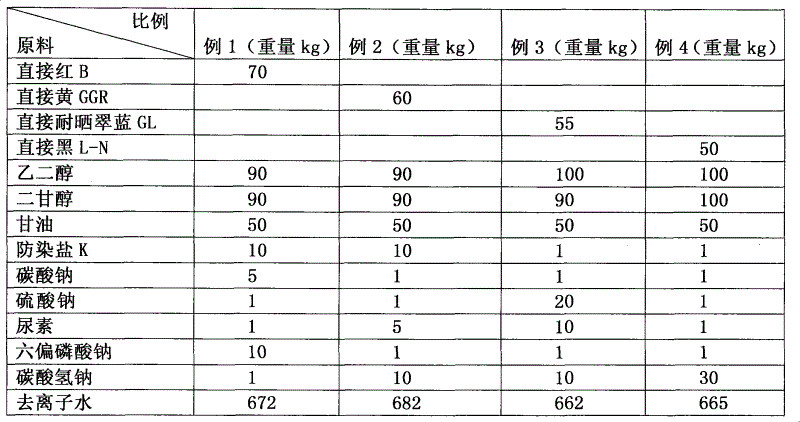

Textile printing and dyeing ink and preparation method thereof

The invention relates to a textile printing and dyeing ink which is prepared from the following components in percentage by weight: dye, glycol, diethylene glycol, glycerol, reserve salt K, sodium carbonate, sodium sulfate, urea, sodium bicarbonate, sodium hexametaphosphate and de-ionized water. The textile printing and dyeing ink comprises red printing and dyeing ink / yellow printing and dyeing ink / blue printing and dyeing ink / black printing and dyeing ink. The preparation method comprises the following steps of: respectively weighing the dye, the glycol, the diethylene glycol, the glycerol, the glycerol reserve salt K, the sodium carbonate, the sodium sulfate, the urea, the sodium bicarbonate, the sodium hexametaphosphate and the de-ionized water in percentage by weight; and uniformly stirring and mixing in a mixing vessel, standing and filtering to obtain the finished product textile printing and dyeing ink. The invention has the advantages of good quality, low price, bright color, high stability, strong tinctorial power, tiny undissolved substances, suitability for different types of inkjet printers, no blocking due to capability of automatically cleaning the injection head, good fluidity, smooth jet stream, no wrinkle or diffusion on the picture when being directly sprayed on textiles, high color fastness and ultraviolet radiation resistance. The image does not fade after being preserved for 20 years, and the injection head can not be blocked when the inkjet printers are in off state within half a year.

Owner:黄文泉

An autoclaved aerated concrete block moisture content control device

ActiveCN108972856BJet evenlyConducive to direct contactCeramic shaping apparatusElectric machineMoisture sensor

Owner:HENGYANG HENGYU LIGHTWEIGHT INSULATION MATERIAL CO LTD

Novel bridge equipment

InactiveCN107165063AAdjustable footprintAvoid center of gravity shiftRefuge islandsLighting and heating apparatusEngineeringBilateral symmetry

Owner:陈光才

Degassing sheet for jet refining of molten metal and preparation method of degassing sheet

The invention relates to a degassing sheet for jet refining of molten metal and a preparation method of the degassing sheet. The degassing sheet comprises the following components in percentage by mass: 50%-60% of mullite, 10%-20% of white corundum, 20%-30% of alumina micro powder and 2%-5% of clay, wherein all components are combined together by adopting a gel binding agent; the amount of the gel binding agent is 4%-5% of total mass of the components. The preparation method comprises the following steps: sequentially burdening, mixing raw materials, and then pressing and molding on a 2-4MPa of vibration molding machine; and baking at 100-140 DEG C, and then firing into a green brick in a shuttle kiln. The preparation method disclosed by the invention is simple; the prepared degassing sheet has the advantages of small jet aperture, jet uniformity, long service life, small resistance, and relatively low production cost, and is simple and convenient to use; nonferrous metal is not easy to ooze; and the working area and the ventilation efficiency are greater than those of common air bricks.

Owner:江苏苏嘉集团新材料有限公司

Safe insect killing device for forest cultivation

InactiveCN114271244APromote growthEfficient use ofDispersed particle filtrationTransportation and packagingTrappingFishery

The invention discloses a safe insect killing device for forest cultivation, which belongs to the technical field of insect catching and comprises an insect catching cavity, an insect trapping lamp, a pressurizing mechanism, an insect discharging barrel, a water absorbing barrel and a rotating belt. The insect catching cavity is fixedly installed below the pressurizing mechanism, the insect discharging barrel is fixedly installed below the insect catching cavity, the water suction barrel is fixedly installed below the pressurizing mechanism and penetrates through and communicates with the interior of the pressurizing mechanism, the water suction barrel is located in the insect discharging barrel, and the insect trapping lamps are fixedly installed on the outer side of the water suction barrel. The rotating belt is rotationally connected with the inner wall of the water absorption barrel; through the arrangement of the structure, the device can directly use the trapped pests as fish feed to feed fish.

Owner:李卫珍

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com