Jet ink for digital print and preparation method thereof

A technology of inkjet ink and digital inkjet, which is applied in the fields of ink, printing, household utensils, etc. It can solve the problems of human injury, easy fading, easy wrinkle paper, etc., and achieve the effect of smooth jetting, rich colors, and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

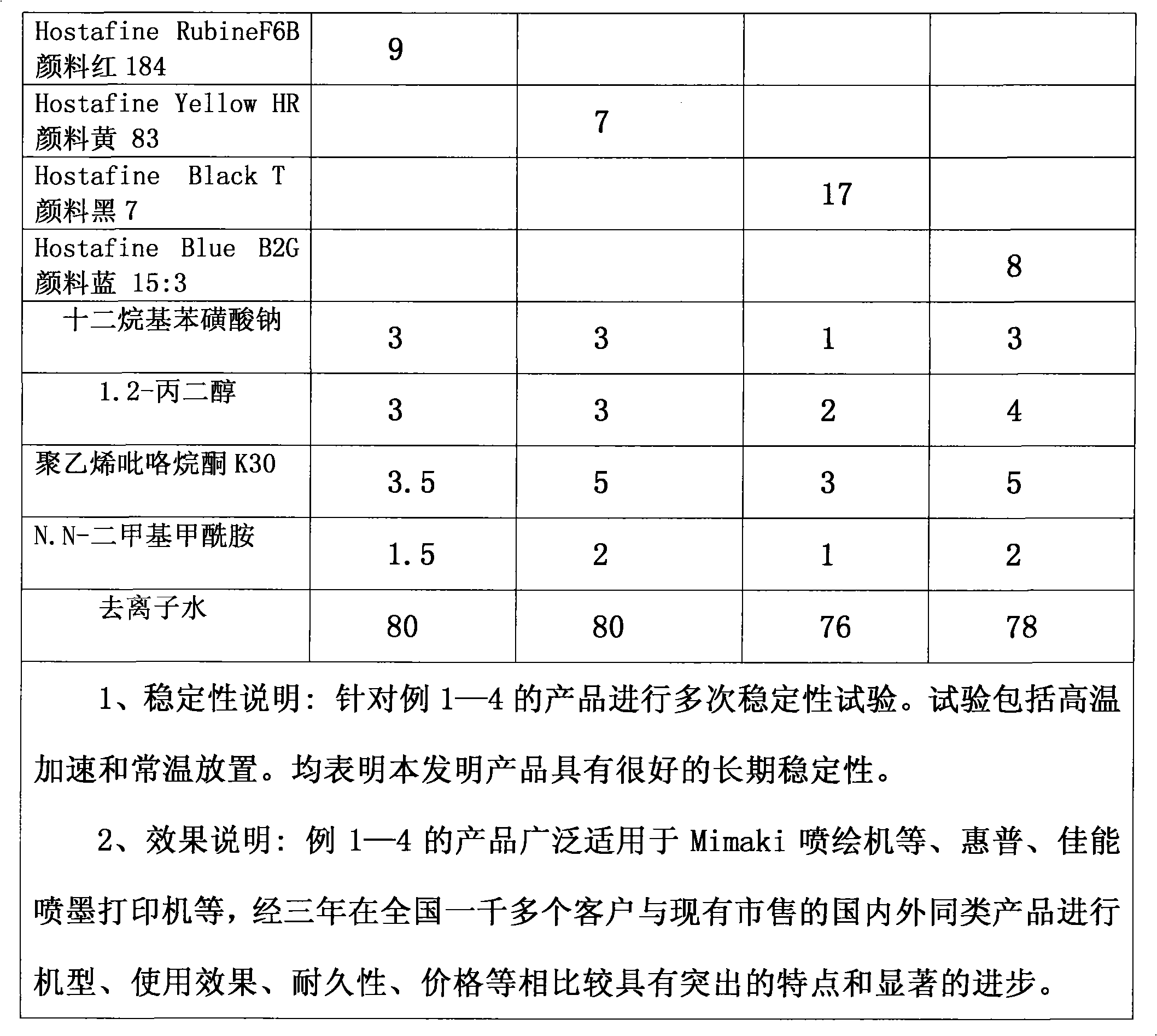

Embodiment 1

[0053] Preparation of red digital inkjet inkjet ink:

[0054] 1). Weigh 9kg of Hostafine Rubine F6B pigment red 184, 3kg of sodium dodecylbenzenesulfonate, and 3kg of 1.2-propylene glycol among the above raw materials, put them into container A, stir, and mix evenly to obtain the pigment The mixture of red, sodium dodecylbenzenesulfonate and 1.2-propylene glycol, spare;

[0055] 2). Weigh 80.0kg of deionized water and 3.5kg of polyvinylpyrrolidone K30 among the above raw materials, take 10% of the total amount of deionized water (8.0kg) and polyvinylpyrrolidone K30 and put them into container B for heating To 98°C, stir until completely dissolved to obtain polyvinylpyrrolidone K30 solution, set aside;

[0056] 3). Put the polyvinylpyrrolidone K30 solution in step 2) into container A of step 1) and stir the mixture of pigment red, sodium dodecylbenzenesulfonate and 1.2-propylene glycol in step 1), and mix well Stand still, get slurry, and set aside;

[0057] 4). Weigh 1.5kg ...

Embodiment 2

[0059] Preparation of yellow digital inkjet inkjet ink:

[0060] 1). Weigh 7kg of Hostafine Yellow HR pigment yellow 83, 3kg of sodium dodecylbenzenesulfonate, and 3kg of 1.2-propylene glycol among the above raw materials, put them into container A, stir, and mix evenly to obtain pigments The mixture of yellow, sodium dodecylbenzenesulfonate and 1.2-propylene glycol, spare;

[0061] 2). Weigh 80.0kg of deionized water and 5kg of polyvinylpyrrolidone K30 among the above raw materials, take 10% of the total amount of deionized water (8.0kg) and polyvinylpyrrolidone K30 and put them into container B and heat to Stir at 98°C until it is completely dissolved to obtain a solution of polyvinylpyrrolidone K30, which is set aside;

[0062] 3). Put the polyvinylpyrrolidone K30 solution in step 2) into container A of step 1) and stir the mixture of pigment yellow, sodium dodecylbenzenesulfonate and 1.2-propylene glycol in step 1), and mix well Stand still, get slurry, and set aside;

...

Embodiment 3

[0065] Preparation of black digital inkjet inkjet ink:

[0066] 1). Hostafine Black T pigment black 7 among the above-mentioned raw materials is weighed 17kg, sodium dodecylbenzene sulfonate 1kg, 1.2-propylene glycol weighs 2kg, puts in A container, stirs, mixes evenly, gets pigment black, The mixture of sodium dodecylbenzene sulfonate and 1.2-propylene glycol, spare;

[0067] 2). Deionized water 76.0kg and polyvinylpyrrolidone K30 weighing 3kg among the above raw materials are taken, and deionized water (7.6kg) and polyvinylpyrrolidone K30 accounting for 10% of the total amount are put into container B and heated to Stir at 98°C until it is completely dissolved to obtain a solution of polyvinylpyrrolidone K30, which is set aside;

[0068] 3). Put the polyvinylpyrrolidone K30 solution in step 2) into container A of step 1) and stir the mixture of pigment black, sodium dodecylbenzenesulfonate and 1.2-propylene glycol in step 1) and mix evenly Stand still, get slurry, and set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com