Gasification agent injection device of biomass gasifier

A technology of injection device and gasification agent, which is applied in the manufacture of combustible gas and petroleum industry, etc. It can solve the problems of polluting the environment, unbearable injection pipes, and harming human body, etc., and achieves high gasification efficiency, compact structure, and avoids overhead effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

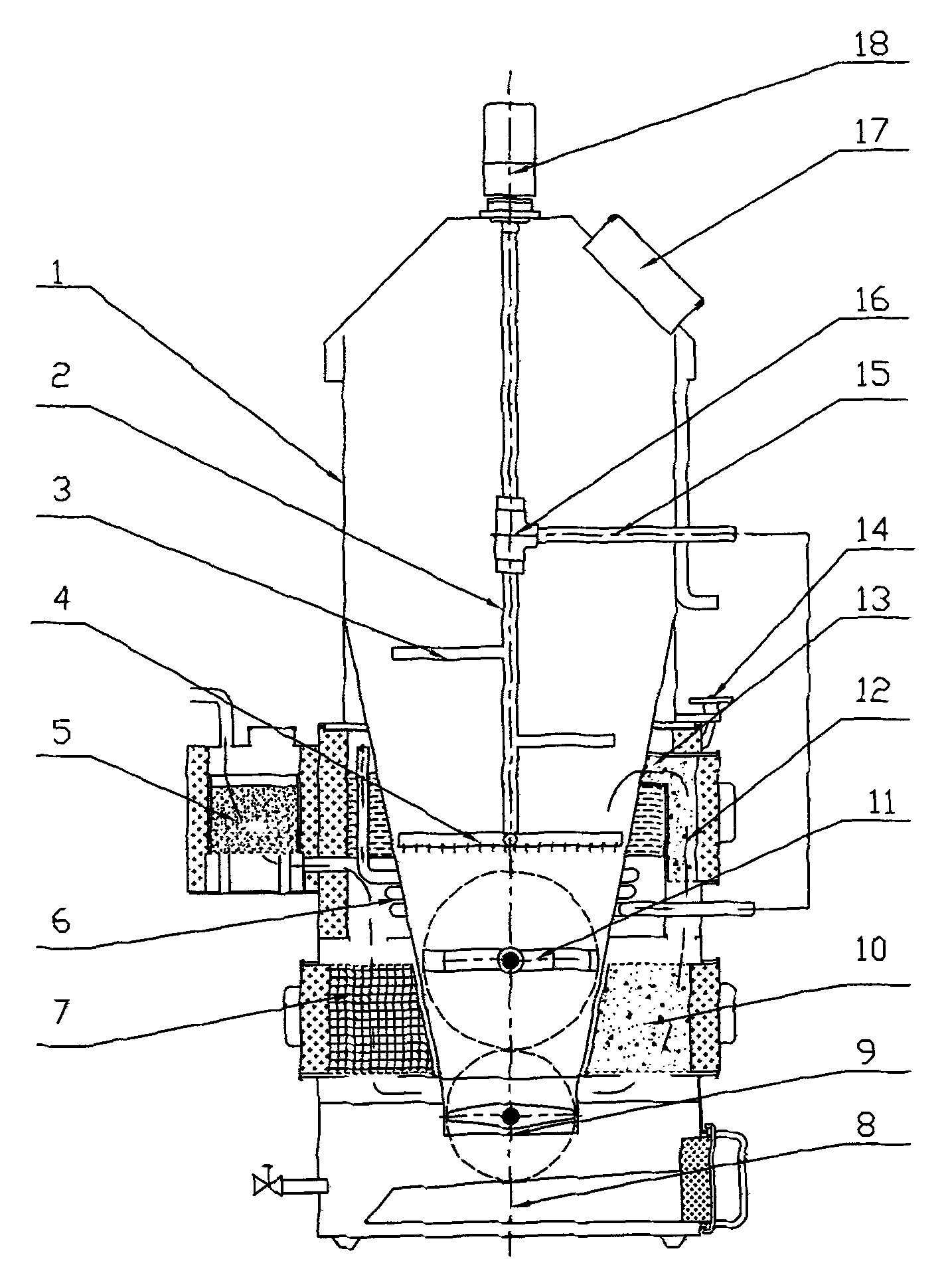

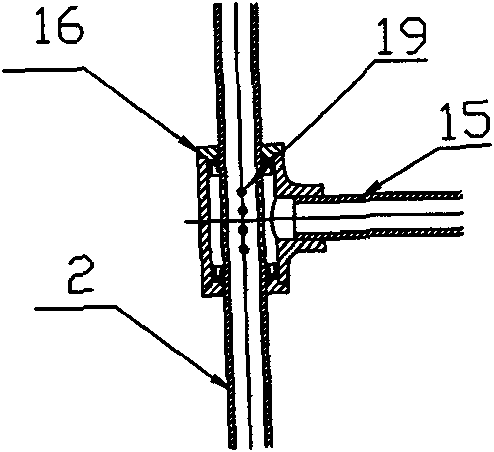

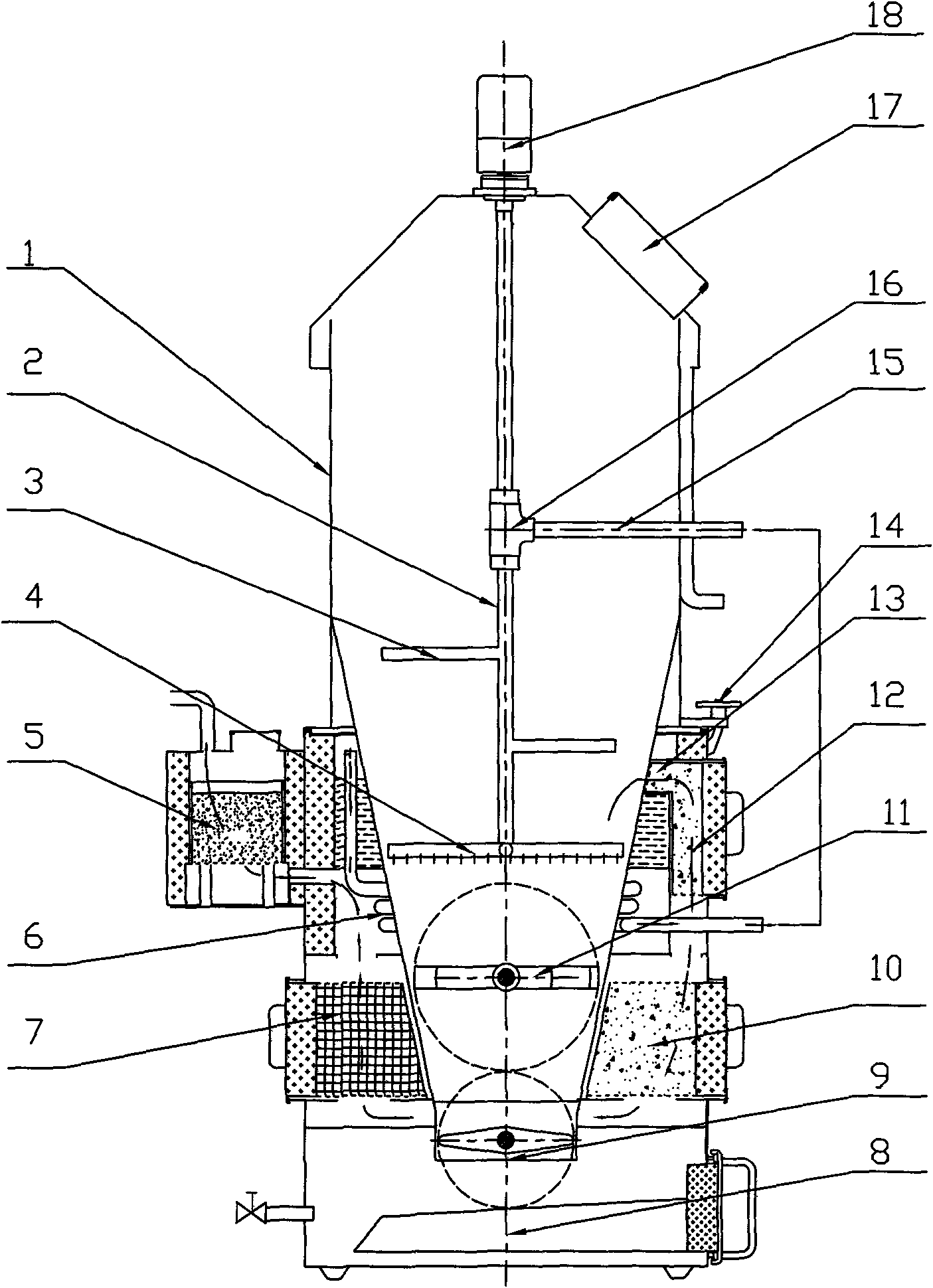

[0012] Such as figure 1 , figure 2 As shown, the biomass gasification furnace in this embodiment includes a furnace body 1, 1-3 first filter boxes 12 and second filter boxes 10 arranged around the furnace body 1, a cracking box 7, a third filter box 5 and a The steam coil 6 in the annular high-temperature chamber; the furnace body 1 includes a charging port 17, 1-3 combustible gas (raw gas) outlets 13 distributed on the furnace body and a rotatable gas outlet 13 arranged at the furnace body ash outlet. Ash cleaning flap 9, a rotatable gasification layer flap 11 arranged in the gasification layer of the furnace body; a gasification agent injection device is provided in the furnace body 1, and the gasification agent injection device includes a gasification agent inlet pipe 15 , the gasification agent outlet pipe 2 standing upright in the furnace body 1, the electric or manual reducer 18 on the top of the furnace, and the intake tee joint 16 fixed in the furnace body, the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com