Novel full-automatic intelligent ironer

A fully automatic ironing machine technology, which is applied in laundry room devices, washing devices, wrinkle-removing and flattening equipment, etc., can solve the problems of prone to human accidents, poor ironing effect of clothes, uneven surface, etc., and achieve shortening The time of manual operation, the reduction of labor cost, the effect of uniform air injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

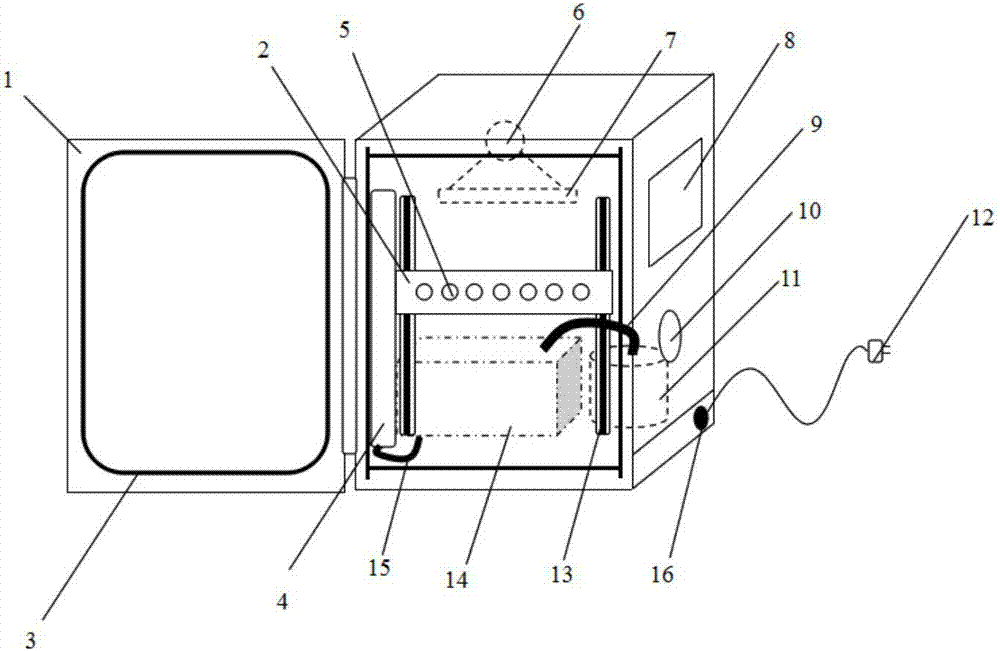

[0020] Embodiment 1: as figure 1 As shown, a new type of automatic intelligent ironing machine mainly includes: body cover 1, steam moving brush 2, sealing ring 3, steam controller 4, steam hole 5, rotator 6, drying rack 7, operation panel 8 , water pipe 9, water inlet 10, water tank 11, external power plug 12, moving rod guide rail 13, steam generator 14, steam pipe 15, power cord jack 16; the body of the ironing machine is in the shape of a cuboid, and the front is hydraulically connected to the body cover Board 1, two moving rod guide rails 13 are installed on the inner wall of the body, the moving rod guide rails 13 are connected to the steam moving brush 2 through rollers, there are a certain number of steam holes 5 on the steam moving brush 2, the steam moving brush 2 and the steam controller 4 Connection, the steam controller 4 is connected to the steam generator 14 through the steam pipe 15, the steam generator 14 is connected to the water tank 11 through the water pip...

Embodiment 2

[0027] Embodiment 2: as figure 1 As shown, a new type of automatic intelligent ironing machine mainly includes: body cover 1, steam moving brush 2, sealing ring 3, steam controller 4, steam hole 5, rotator 6, drying rack 7, operation panel 8 , water pipe 9, water inlet 10, water tank 11, external power plug 12, moving rod guide rail 13, steam generator 14, steam pipe 15, power cord jack 16; the body of the ironing machine is in the shape of a cuboid, and the front is hydraulically connected to the body cover Board 1, two moving rod guide rails 13 are installed on the inner wall of the body, the moving rod guide rails 13 are connected to the steam moving brush 2 through rollers, there are a certain number of steam holes 5 on the steam moving brush 2, the steam moving brush 2 and the steam controller 4 Connection, the steam controller 4 is connected to the steam generator 14 through the steam pipe 15, the steam generator 14 is connected to the water tank 11 through the water pip...

Embodiment 3

[0034] Embodiment 3: as figure 1 As shown, a new type of automatic intelligent ironing machine mainly includes: body cover 1, steam moving brush 2, sealing ring 3, steam controller 4, steam hole 5, rotator 6, drying rack 7, operation panel 8 , water pipe 9, water inlet 10, water tank 11, external power plug 12, moving rod guide rail 13, steam generator 14, steam pipe 15, power cord jack 16; the body of the ironing machine is in the shape of a cuboid, and the front is hydraulically connected to the body cover Board 1, two moving rod guide rails 13 are installed on the inner wall of the body, the moving rod guide rails 13 are connected to the steam moving brush 2 through rollers, there are a certain number of steam holes 5 on the steam moving brush 2, the steam moving brush 2 and the steam controller 4 Connection, the steam controller 4 is connected to the steam generator 14 through the steam pipe 15, the steam generator 14 is connected to the water tank 11 through the water pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com