A cooling device for an automatic ironing machine

A cooling device and ironing machine technology, applied in the direction of heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of low production efficiency and high cost, reduce labor costs, improve production efficiency, shorten the required the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

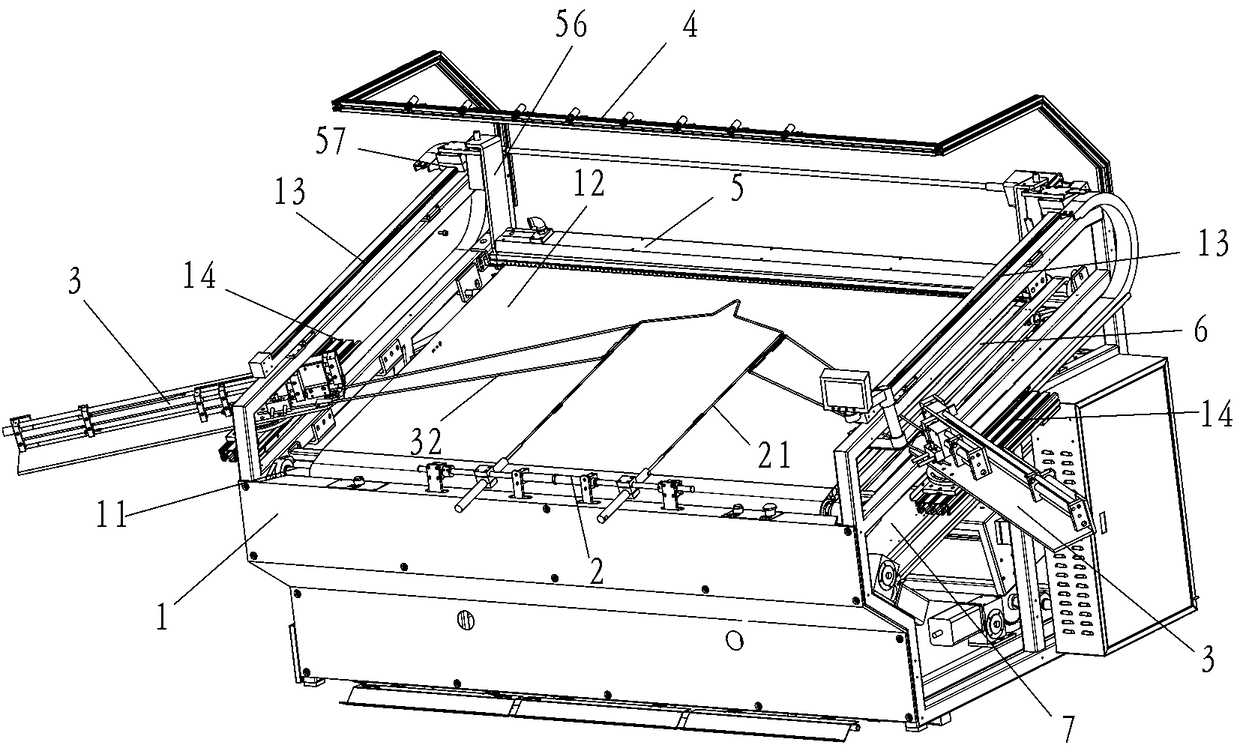

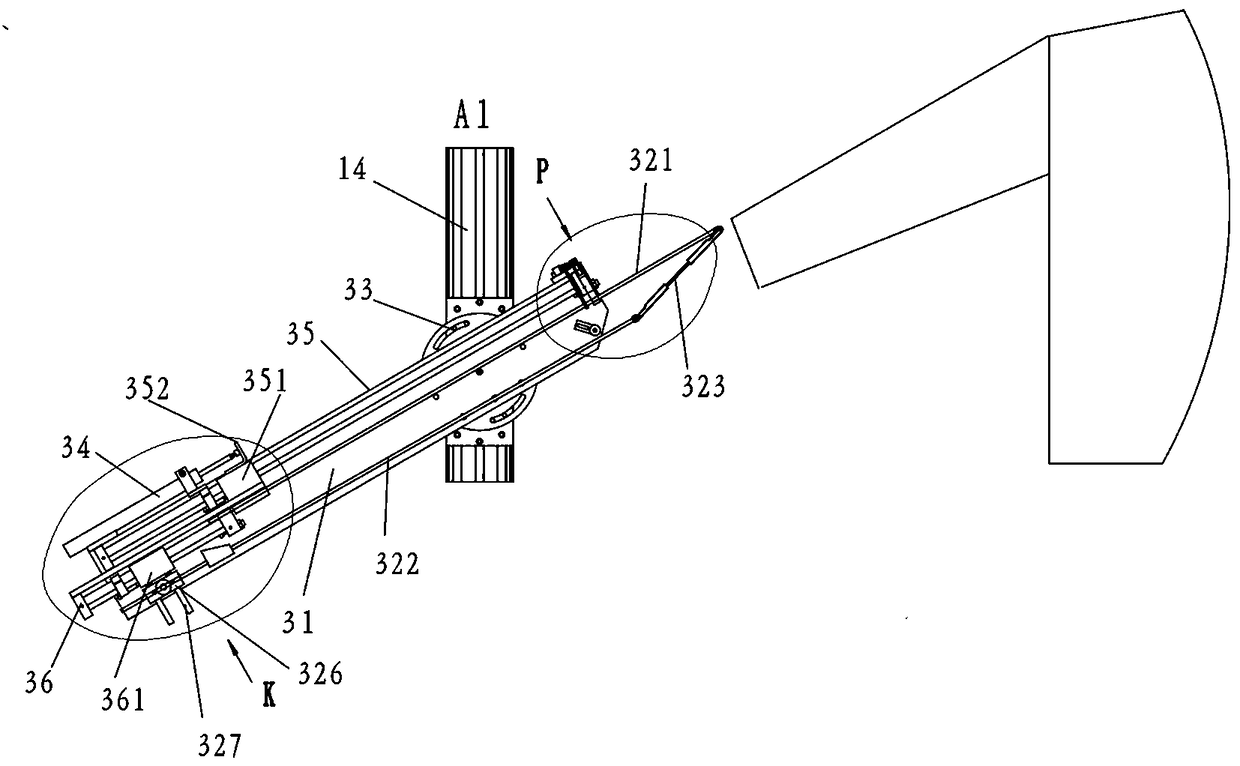

[0029] See attached picture. The automatic ironing machine of the present embodiment comprises a frame 1, a shaping device, a sizing device 5, an ironing platform 6, a conveying and receiving device 7 and a power unit; The transmission shaft 11 is covered with a conveyor belt 12 on the transmission shaft 11, and the transmission shaft 11 drives the conveyor belt 12 to move; the power unit has control components such as a stepping motor and an air source filter.

[0030] The shaping device of the present embodiment comprises a body shaping device 2, a sleeve shaping device 3 and an infrared laser lamp group 4. The infrared laser lamp group 4 is installed above the frame 1. During work, the infrared laser lamp group 4 steps on different parts of the clothes. , to ensure that the same clothes have the same shaping strength.

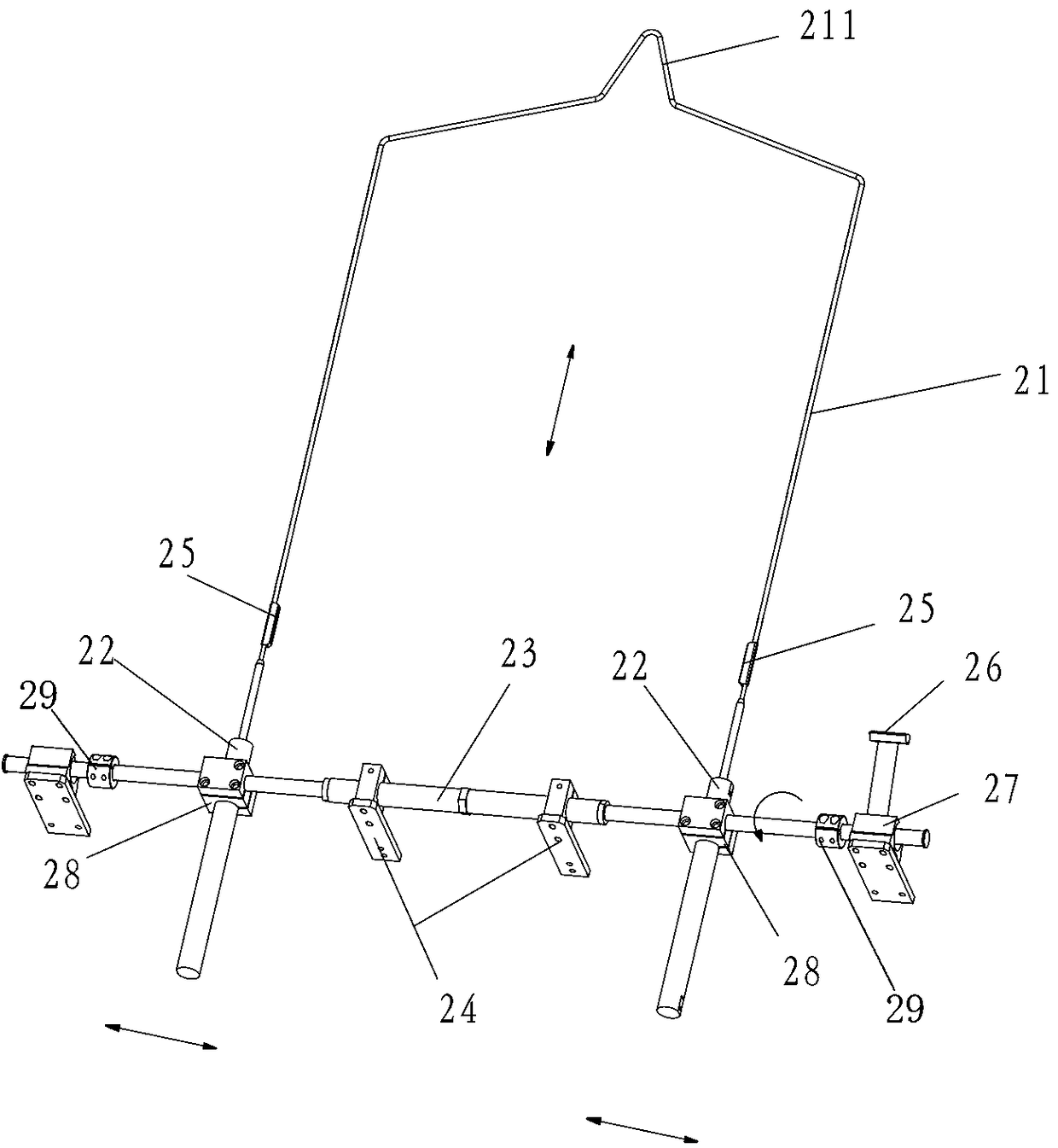

[0031] The body shaping device 2 of the present embodiment includes a body bar 21 and a body control assembly, the body control assembly is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com