Shaping device for automatic ironer

The technology of a setting device and an ironing machine is applied in the field of clothing production equipment, which can solve the problems of low production efficiency and high cost, and achieve the effects of reducing labor costs, improving production efficiency, and improving the effect of finishing clothes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

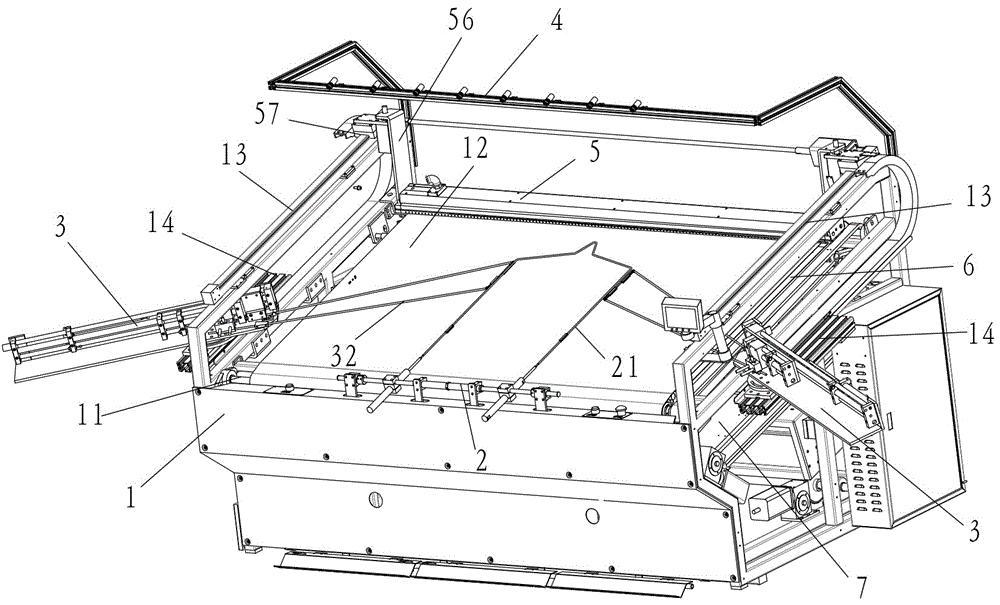

[0029] See attached image. The automatic ironing machine of this embodiment includes a frame 1, a shaping device, a setting device 5, an ironing platform 6, a conveying and receiving device 7 and a power device; the front and rear sides of the frame 1 are provided with a power device connected to the power device The transmission shaft 11 is covered with a conveyor belt 12, and the transmission shaft 11 drives the conveyor belt 12 to move; the power device has control components such as a stepper motor and an air source filter.

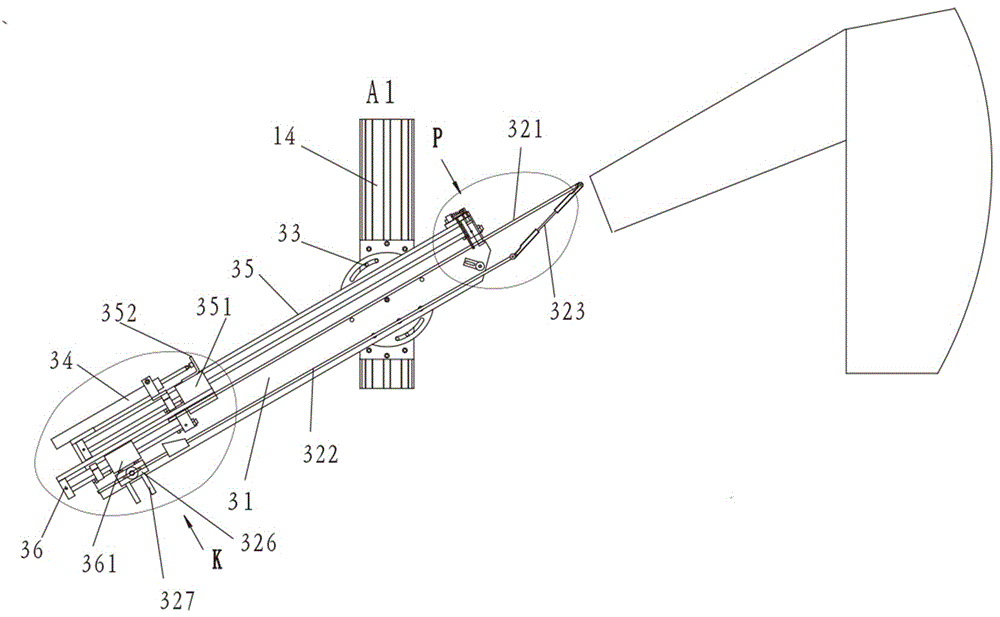

[0030] The shaping device in this embodiment includes a body shaping device 2, a sleeve shaping device 3, and an infrared laser light group 4. The infrared laser light group 4 is installed above the rack 1. During operation, the infrared laser light group 4 steps on different parts of the clothes. , to ensure that the same style of clothing has the same shaping force.

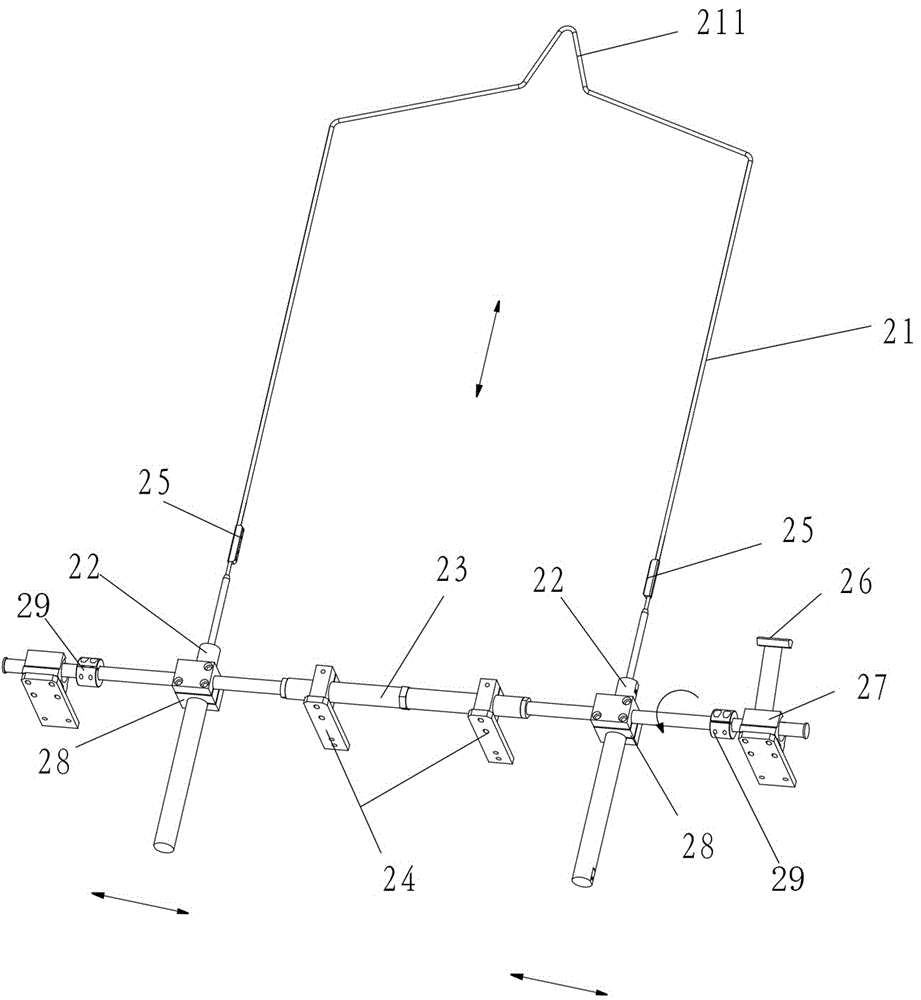

[0031] The body shaping device 2 of this embodiment includes a body bar 21 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com