Cooling and ventilating equipment for box-type transformer substation, and using method thereof

A box-type substation, cooling and ventilation technology, applied in the field of substations, can solve problems such as equipment damage, high temperature in substations, and inability to achieve gas filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

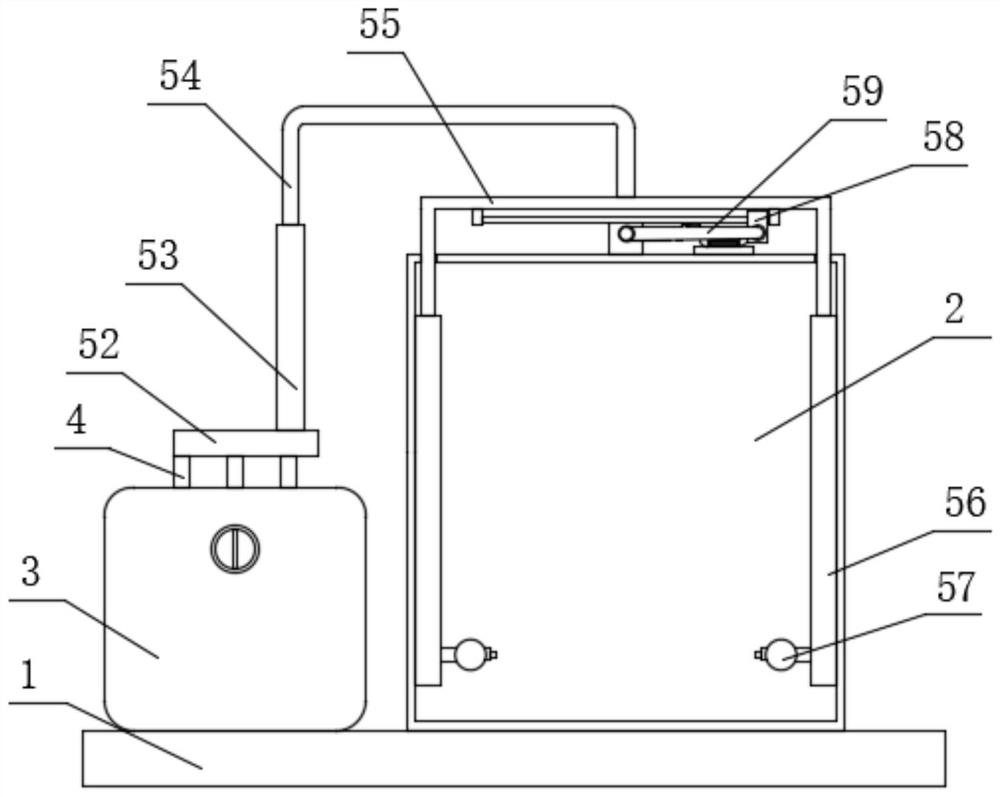

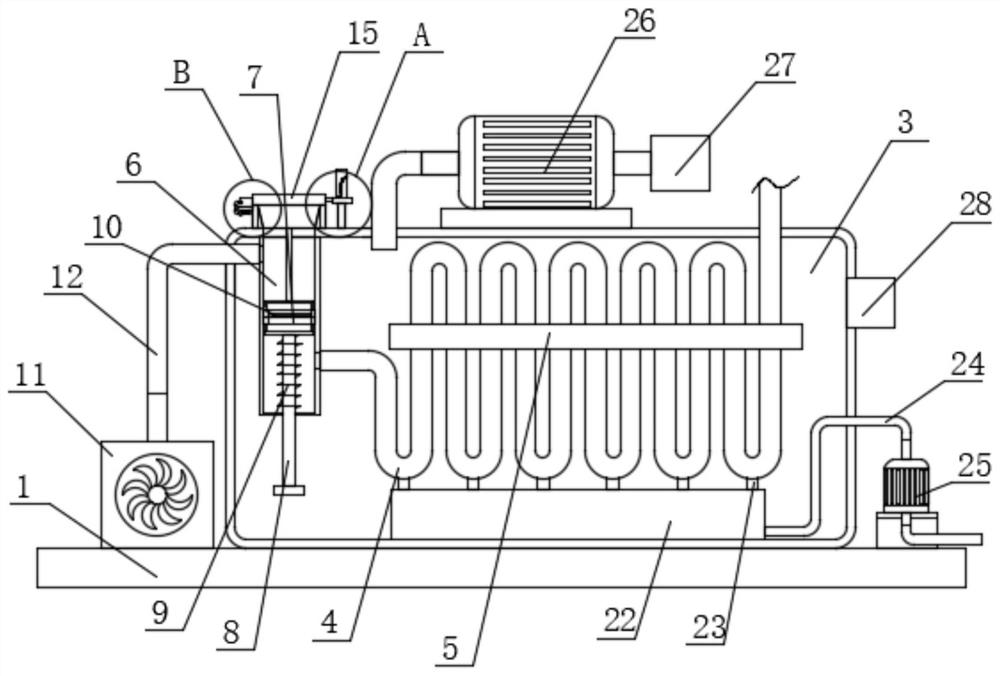

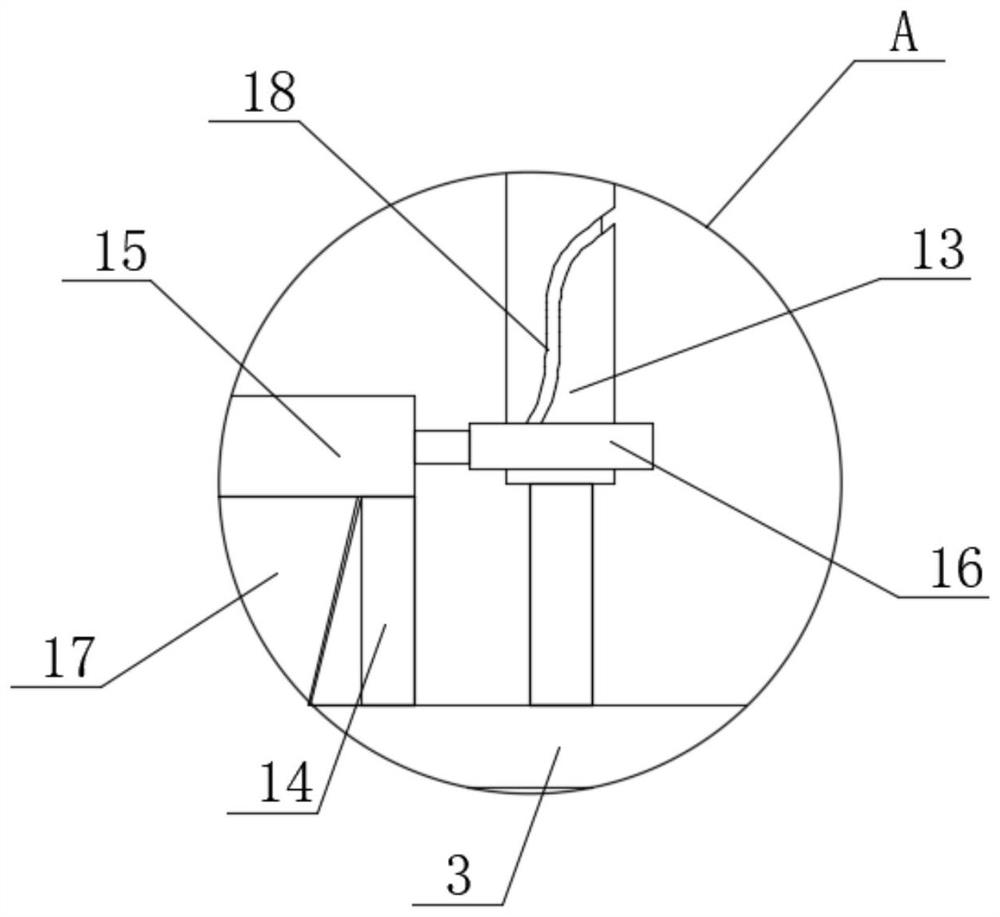

[0049] Embodiment one: if Figure 1-10As shown, a cooling ventilation device for a box-type substation includes a base 1, and the top of the base 1 is respectively fixed with a substation box 2 and a cooling box 3, and the cooling box 3 is located on one side of the substation box 2, cooling The dust removal assembly is fixedly installed on the inner wall of the top side of the box 3, and the top of the base 1 is fixedly installed with a turbo fan 11 on one side of the cooling box 3, and an air delivery pipe 12 is fixedly installed on the outlet end of the turbo fan 11, and the air delivery pipe One end of 12 extends into the cooling box 3 and communicates with the dust removal assembly. A fixed plate 5 is fixedly installed in the cooling box 3, and a plurality of heat exchange tubes 4 are fixedly installed on the fixed plate 5 at equal intervals. A plurality of heat exchange tubes 4 One end of each is connected with the dust removal assembly, and the bottom inner wall of the ...

Embodiment 2

[0065] Embodiment two: if Figure 11-15 As shown, a cooling ventilation device for a box-type substation. The difference between this embodiment and Embodiment 1 is that the power assembly includes a drive motor 66 fixedly installed on the top of the substation box 2 and slidingly connected to the top of the substation box 2. The mobile frame 60, one side of the mobile frame 60 is fixedly equipped with a transmission ring 67, and the output shaft of the drive motor 66 is fixedly equipped with a transmission roller 64, the transmission roller 64 runs through the transmission ring 67, and the transmission roller 64 is provided with a transmission port 65 , and one side of the inner wall of the transmission ring 67 is fixed with a stop shaft 68, one end of the stop shaft 68 extends into the transmission port 65 and is connected with the inner wall of the transmission port 65, and the top of the substation box 2 is connected with a connecting shaft 62 for rotation. , and one end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com