Square tube punching die

A punching die and cutting technology, which is applied in the field of tubular object cutting devices, can solve problems such as slow speed and irregular cutting openings, and achieve the effect of increasing cutting speed and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

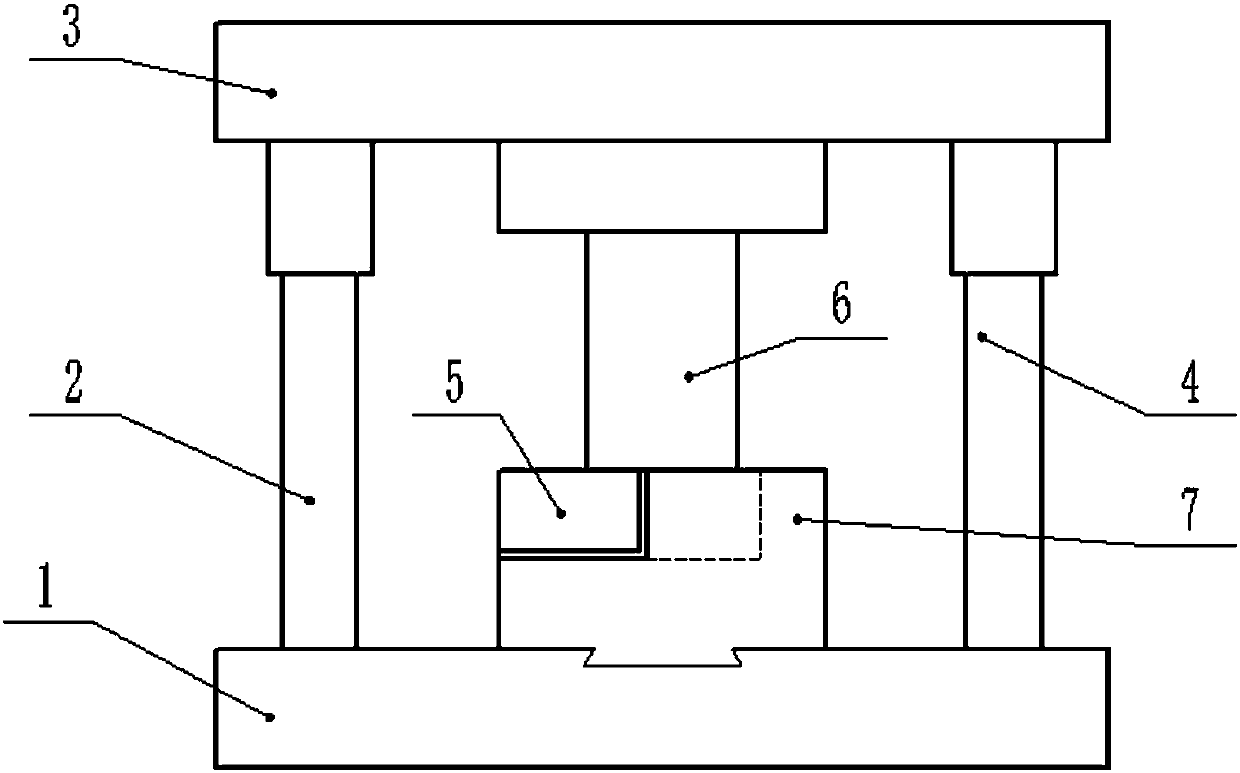

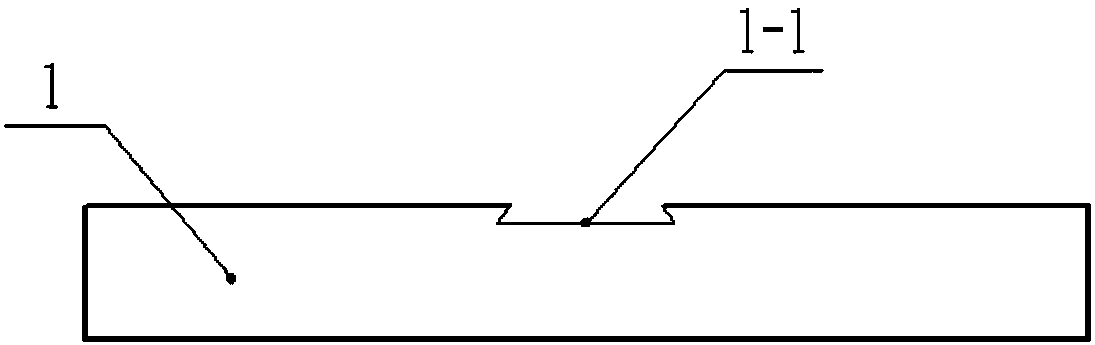

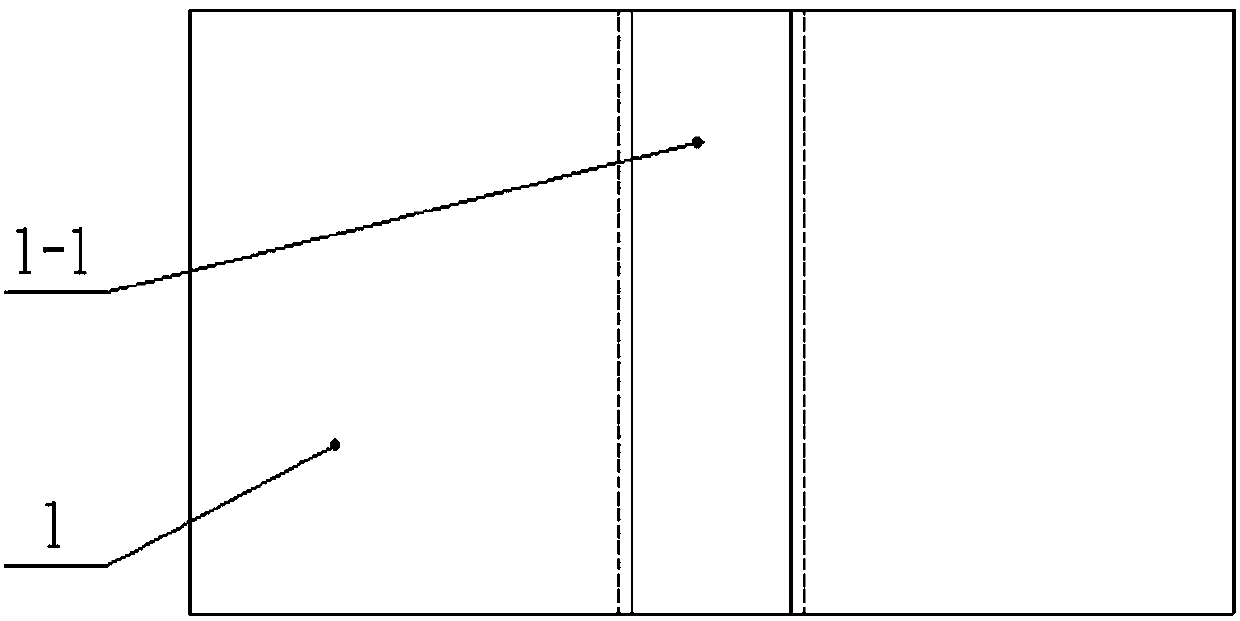

[0015] Attached below figure 1 — Figure 7 A square tube punching die of the present invention will be further described in detail.

[0016] In order to achieve the purpose of this technical solution, the present invention adopts following technical solution:

[0017] A kind of square tube punching die of the present invention is characterized in that comprising: fixed support plate (1), left side plate (2), upper top plate (3), right side plate (4), cut square tube ( 5), consisting of a punch (6), a support (7), and a cutout (8), the fixed support plate (1) is provided with a left side plate (2), a right side plate (4) and a support (7), the left side plate (2) and the right side plate (4) are fixed on the fixed support plate (1) by bolts, and the support (7) is stuck on the fixed support plate (1) through a V-shaped groove , it can be moved back and forth as needed to find the correct position.

[0018] Further, the square tube punching die is characterized in that: the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap