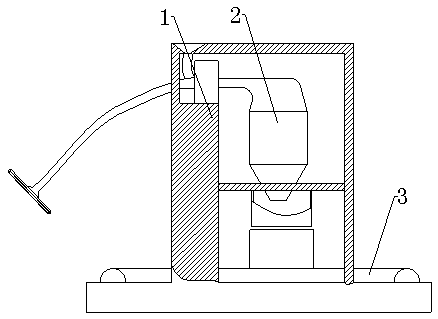

Dust removing machine for wood processing

A technology for removing machine and dust, which is applied in the direction of wood processing equipment, bark area/debris/dust/waste removal, manufacturing tools, etc. It can solve the problems of reducing the working efficiency of the device, difficulty in collecting dust and separating, and low working efficiency. Achieve the effect of simple structure, convenient use and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

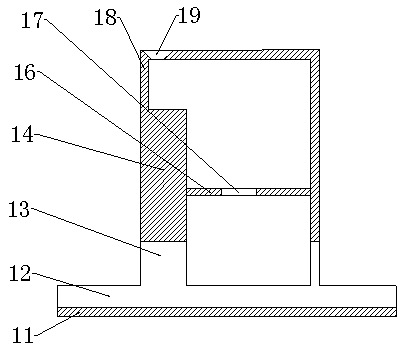

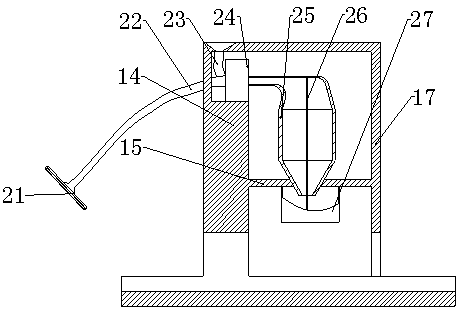

[0025] Specific implementation method: when the staff uses it, install the corresponding dust suction head 21 according to the dust form that needs to be removed and place the dust suction head 21 at the position that needs dust removal. 21 is sucked into the hose 22, and then enters the interior of the negative pressure fan 24 through the airflow inlet of the negative pressure fan 24, and the dust enters the interior of the dust container 25 through the airflow outlet of the negative pressure fan 24 under the action of the airflow. The dust in the air has a wide range of applications and high work efficiency. The dust floating in the air enters the hard pipe 23 through the cone hole 18 under the action of the air flow, and then enters the negative pressure fan 24 through the air inlet of the negative pressure fan 24, and then passes through the negative pressure fan. 24 The airflow outlet enters the dust container 25, and this design can absorb the dust floating in the air to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com