Vacuum cleaner with filter element

A filter and vacuum cleaner technology, which is applied in the direction of vacuum cleaners, cleaning filter devices, suction filters, etc., to achieve the effect of increasing the flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

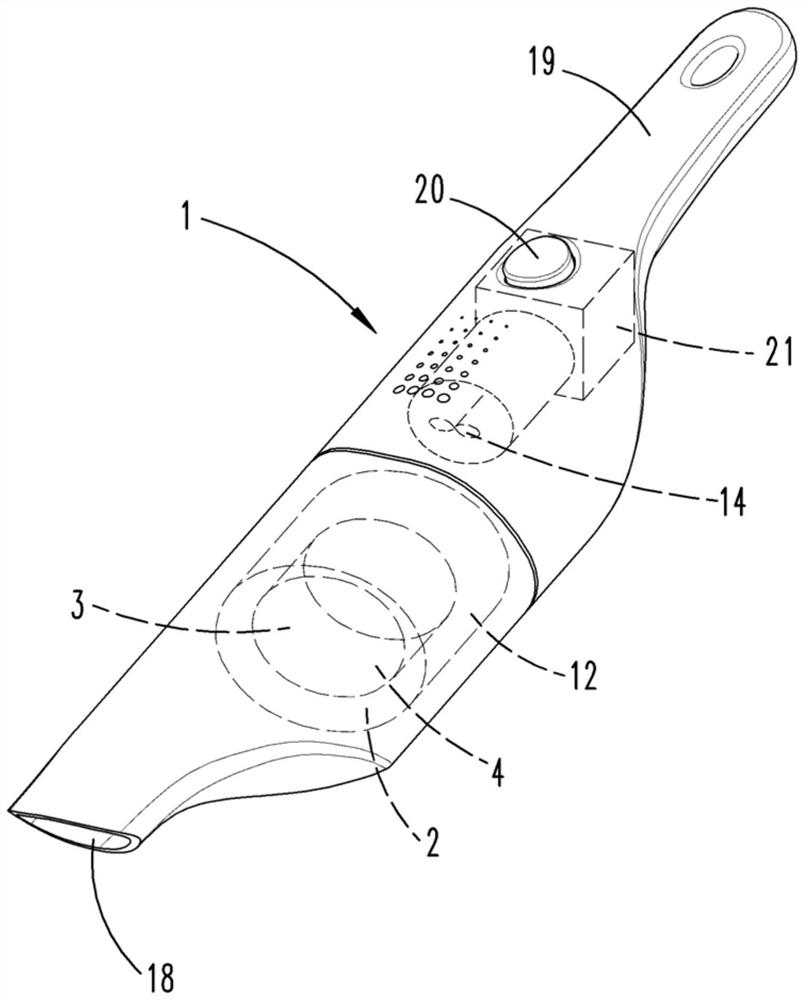

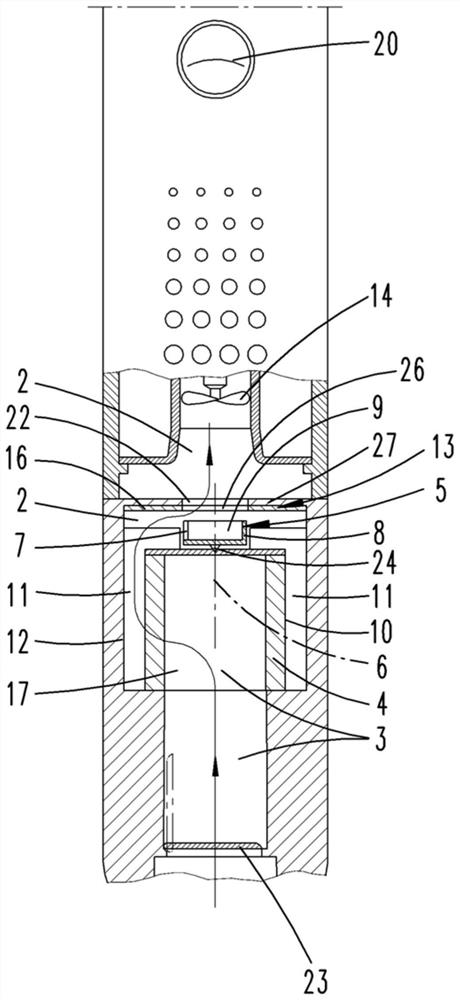

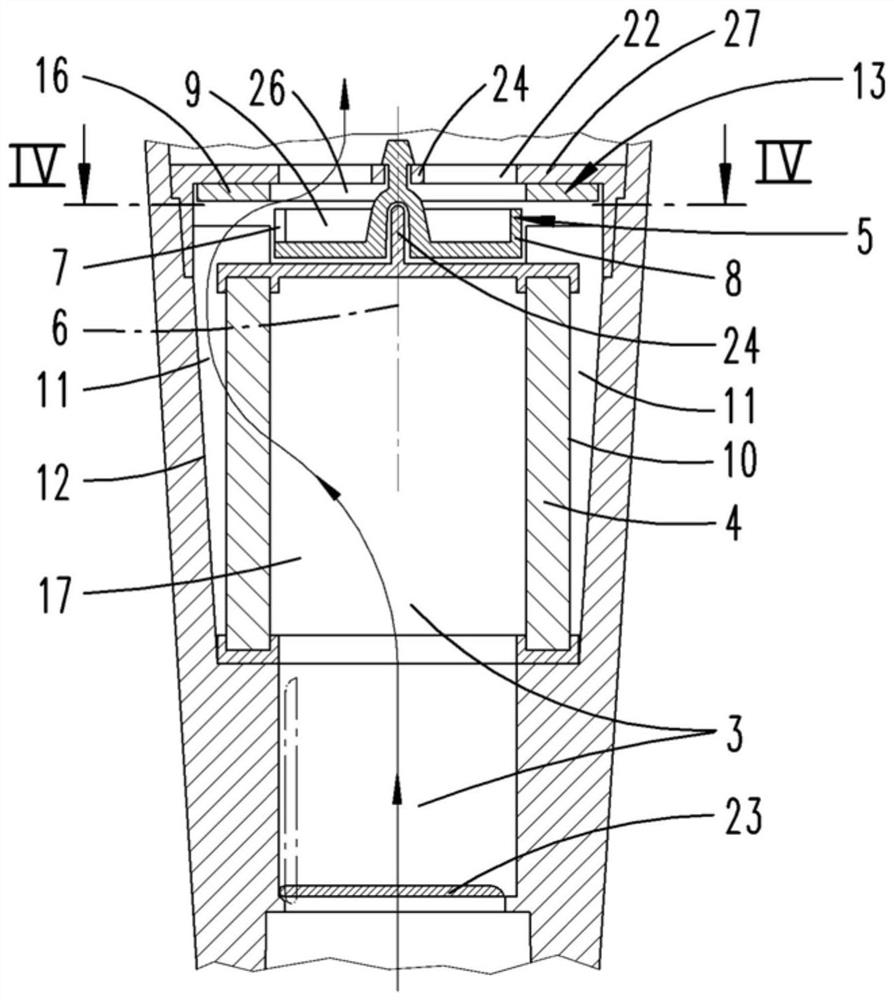

[0030] figure 1 A vacuum cleaner is shown, which is here designed as a hand-held battery vacuum cleaner. The vacuum cleaner 1 has a housing with a suction nozzle 18 and a handle 19 by means of which a user can hold the vacuum cleaner 1 in his hand and guide the vacuum cleaner. Arranged on the handle 19 is a switch 20 for switching on and off a motor 21 which drives the fan 14 . The vacuum cleaner 1 also has a filter chamber 12 with a filter element 4 which is here designed as a regenerable long-term filter. The filter element 4 separates the filter chamber 12 into a clean air chamber 2 and a suction chamber 3 . During normal filter operation of the vacuum cleaner 1 , the fan 14 sucks in air and the suctioned material enters the suctioned material chamber 3 through the suction nozzle 18 . The aspirated suction remains in the suction chamber 3 so that only cleaned air can reach the fan 14 .

[0031] During suction operation, the suction product in the suction product chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com