Fibre guiding element for spinneret of air-jet spinning machine and method for operating air-jet spinning machine

A technology for air-jet spinning machines and guiding elements, which is applied to spinning machines, free-end spinning machines, and continuous winding spinning machines. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

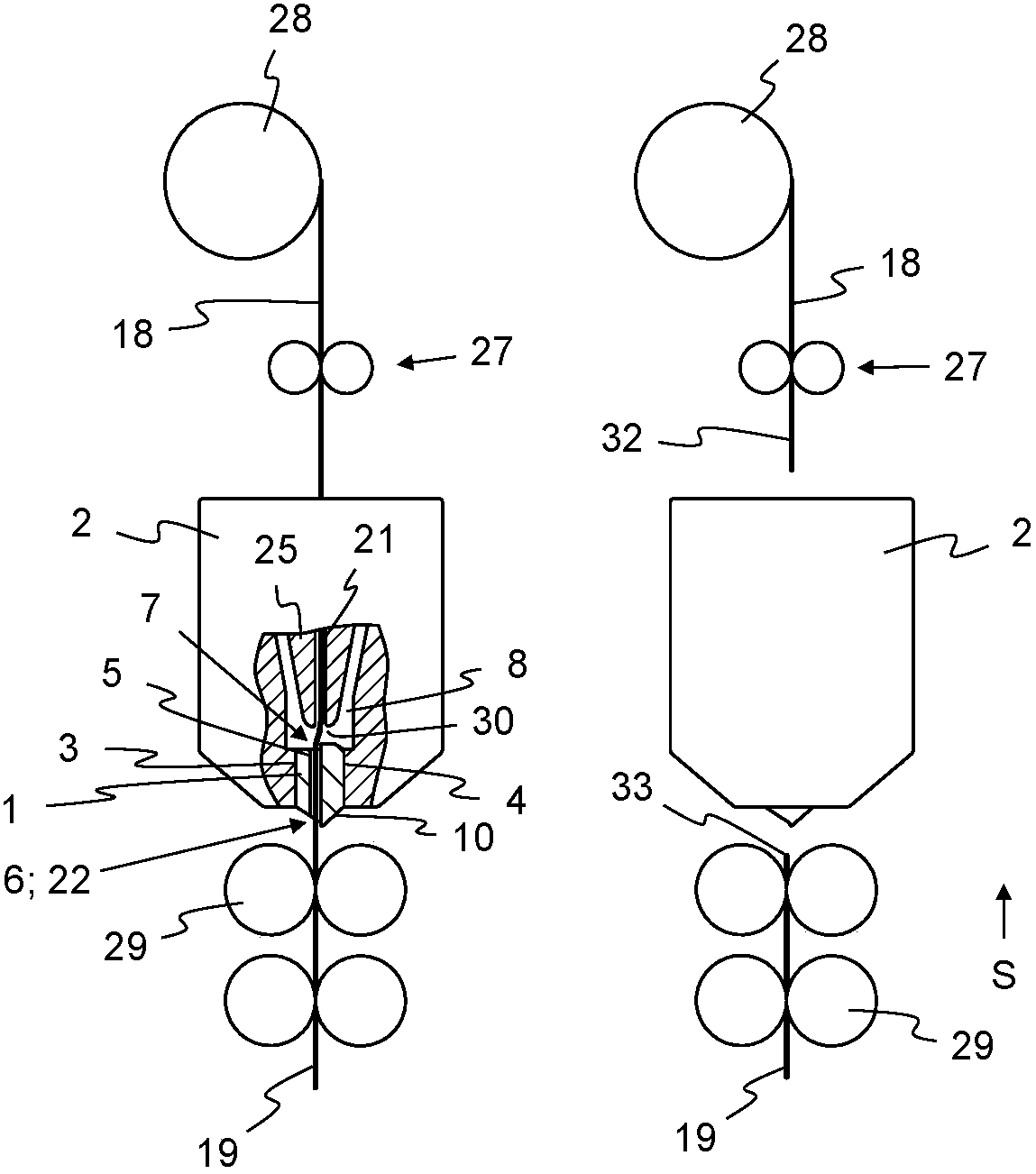

[0071] figure 1 Two essentially identically constructed spinning zones of an air-jet spinning machine are shown, the individual components of the air-jet spinning machine described below also being components of the spinning zone according to the invention.

[0072] The spinning sections each have a drafting unit for finishing the composite fibers 19 comprising a plurality of drafting unit rollers 29 (not all similarly shown drafting unit rollers 29 use a single reference numeral). Furthermore, there are spinning nozzles 2 , wherein the spinning nozzle 2 of the left spinning zone is shown in partial section. The spinning nozzle 2 has an inlet opening 22 through which the composite fiber 19 enters the spinning nozzle 2 , wherein the inlet opening 22 is preferably formed by the inlet opening 6 of the individual fiber guide element 1 .

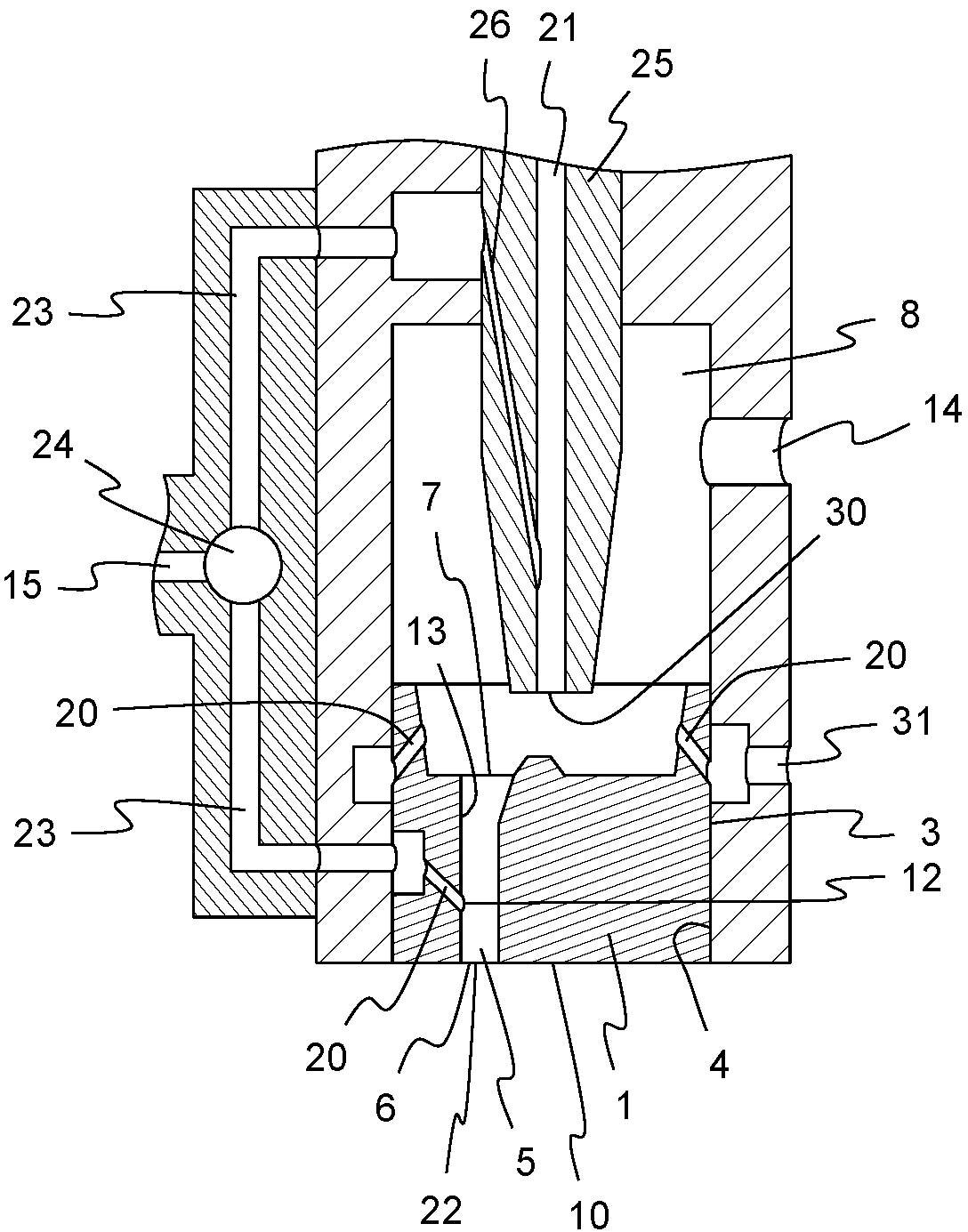

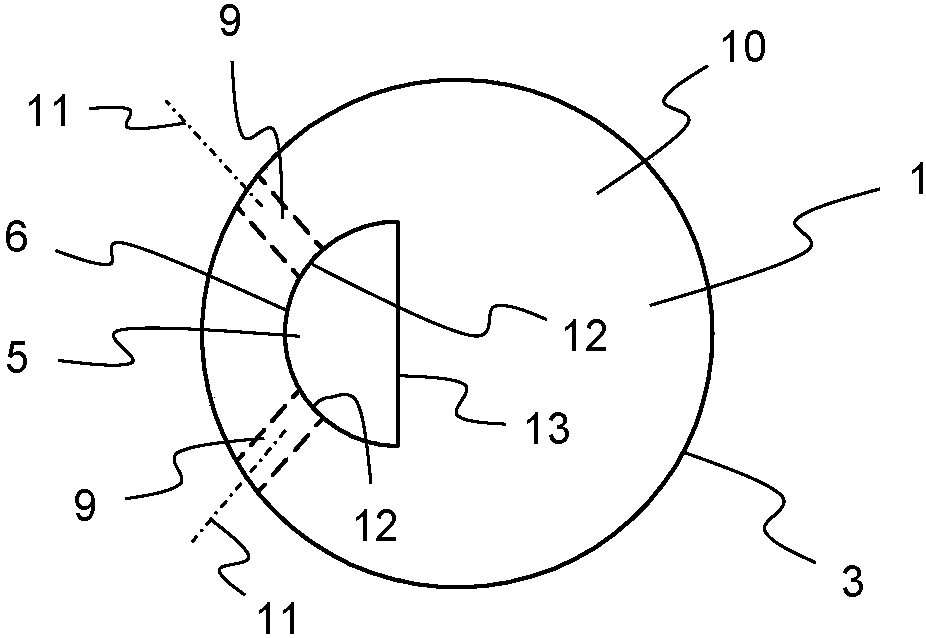

[0073] The fiber guiding element 1 has an outer surface 3 (see figure 2 , which shows a cross-section of a possible embodiment of a spinning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com