Three-way double-column single-screw casing multidimensional structure clip

A single-screw and sleeve technology, which is applied in the connection of rods, connecting components, mechanical equipment, etc., can solve the problems of small contact area between sheet and strip, large number of bolts and nuts, and inconvenient clamping operation. Achieve better clamping effect, convenient interchangeability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

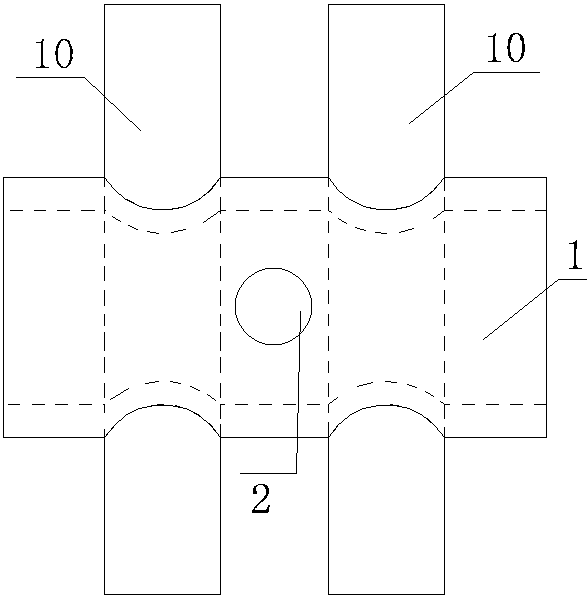

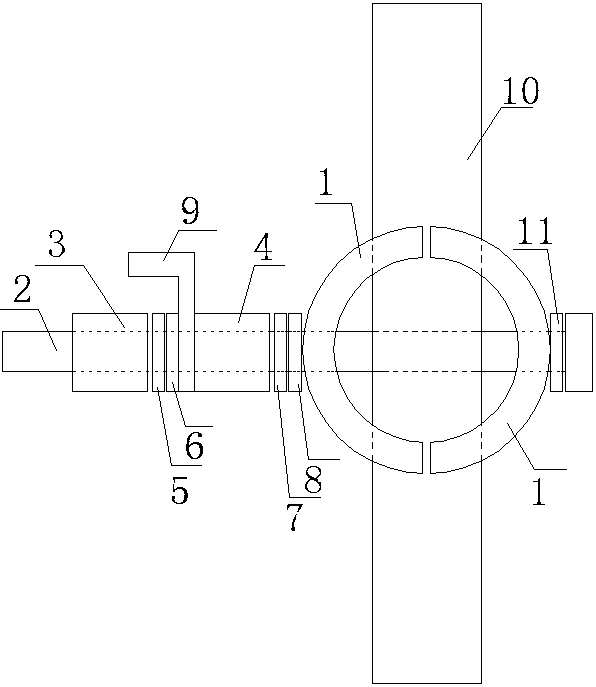

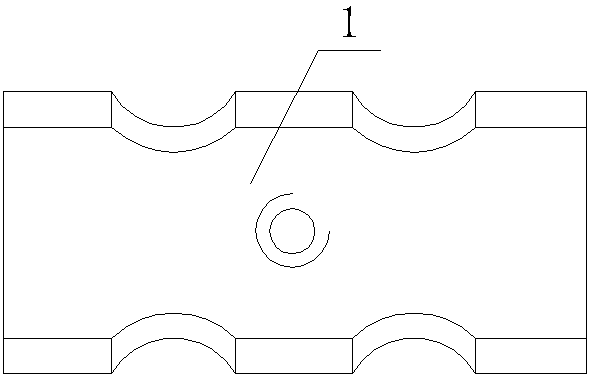

[0025] Embodiment one, such as Figure 1 to Figure 3 As shown, the three-way double-column single-screw bushing single clamp includes a semi-circular tubular clip 1, a bolt 2 and a nut 2 4; the semi-circular tubular clip 1 is two pieces, and the two semi-circular tubular clips 1 are combined Form a circular tube; the middle part of the semicircular tubular clip 1 is provided with a threaded hole, and the threaded hole is matched with the bolt 2; the cross section of the semicircular tubular clip 1 runs through two semicircular holes in the longitudinal direction; two semicircular tubular clips 1 are combined to form After the circular tube shape, the semi-circular holes vertically penetrating on the two semi-circular tubular clips 1 correspond to form longitudinally penetrating round holes, and the threaded holes in the middle of the two semi-circular tubular clips 1 correspond to each other, and the bolts 2 pass through the threaded holes and pass through the nuts. 2. 4 is ti...

Embodiment 2

[0032] Embodiment two, such as Figure 4 to Figure 6 As shown, the three-way double-column single-screw casing multi-dimensional structure clip includes a three-way double-column single-screw casing single-piece clip, and the three-way double-column single-screw casing multi-dimensional structure clip is composed of multiple three-way double-column single The screw casing is composed of a single clip and a composite connection.

[0033] Preferably, the three-way double-column single-screw bushing single clamp includes a semicircular tubular clip 1, a bolt 2 and a nut 24; the semicircular tubular clip 1 is two pieces, and the two semicircular tubular clips 1 are combined Form a circular tube; the middle part of the semicircular tubular clip 1 is provided with a threaded hole, and the threaded hole is matched with the bolt 2; the cross section of the semicircular tubular clip 1 runs through two semicircular holes in the longitudinal direction; two semicircular tubular clips 1 ar...

Embodiment 3

[0040] Embodiment three, such as Figure 7 As shown, a three-way double-column single-screw casing multi-dimensional structure clip includes a three-way double-column single-screw casing single-piece clip, and the three-way double-column single-screw casing multi-dimensional structure clip is composed of a plurality of three-way double It is composed of single-screw sleeve, single clamp and buckle integrated composite connection.

[0041] Preferably, the three-way double-column single-screw bushing single clamp comprises a semicircular tubular clip 1, a bolt 2 and a nut 2 4; the semicircular tubular clip 1 is provided with a threaded hole, and the direction of the threaded hole is any direction, and the screw thread The hole is matched with the bolt 2; the cross-section of the semicircular clip 1 has two semicircular holes through it, and the penetrating direction of the two semicircular holes is any direction; after the two semicircular clips 1 are combined to form a circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com