Raceway groove depth detection gauge

A technology of depth detection and raceway groove, which is used in the field of measuring tools for the depth detection of raceway grooves, can solve the problems of cumbersome measurement process and inaccurate measurement of parts, and achieves the effect of wide measurement range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

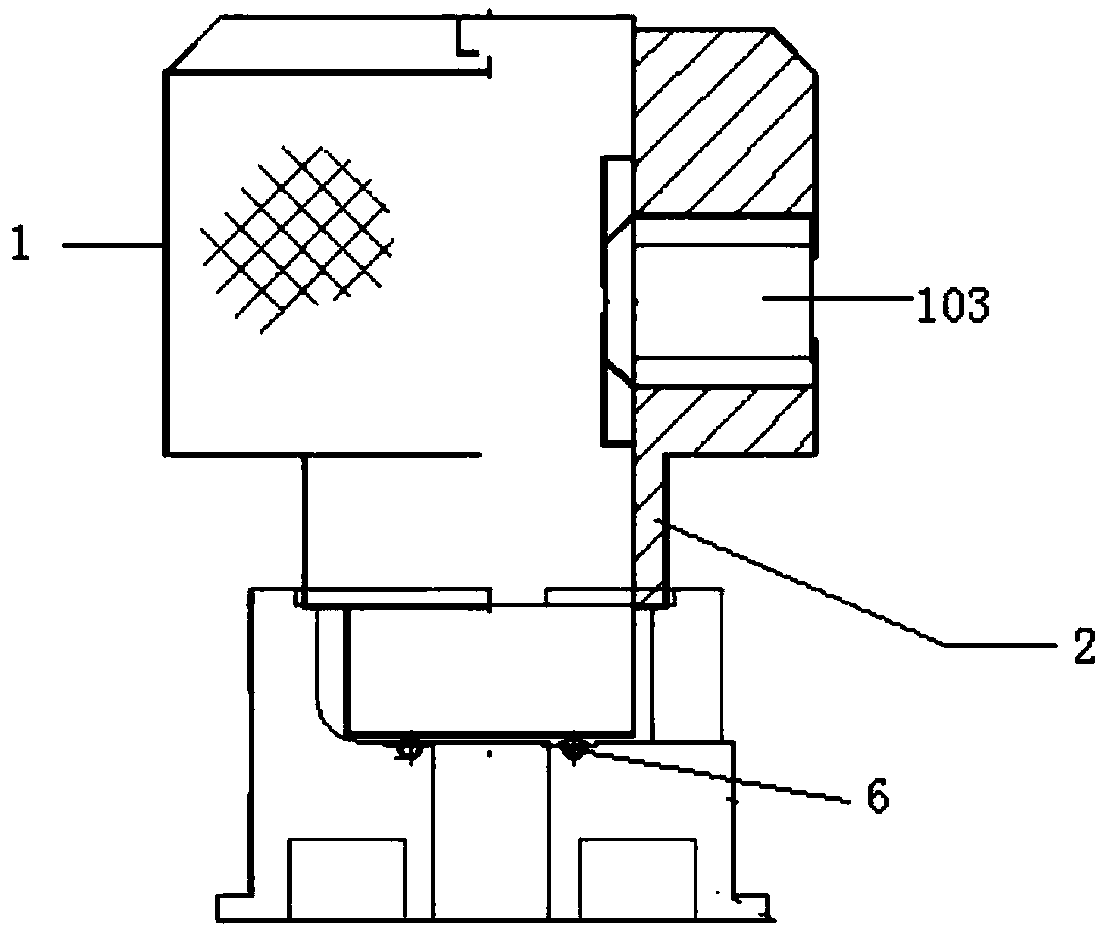

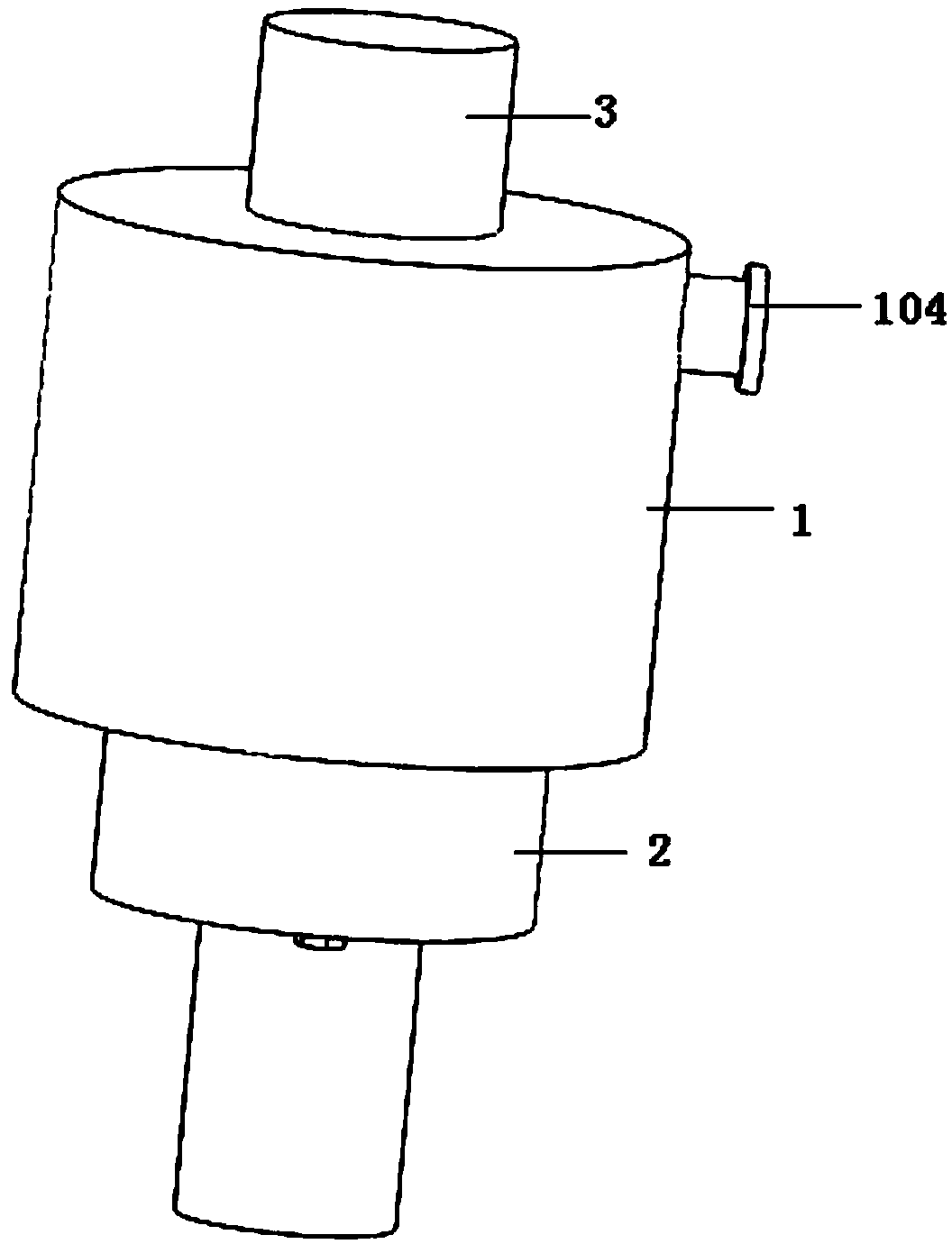

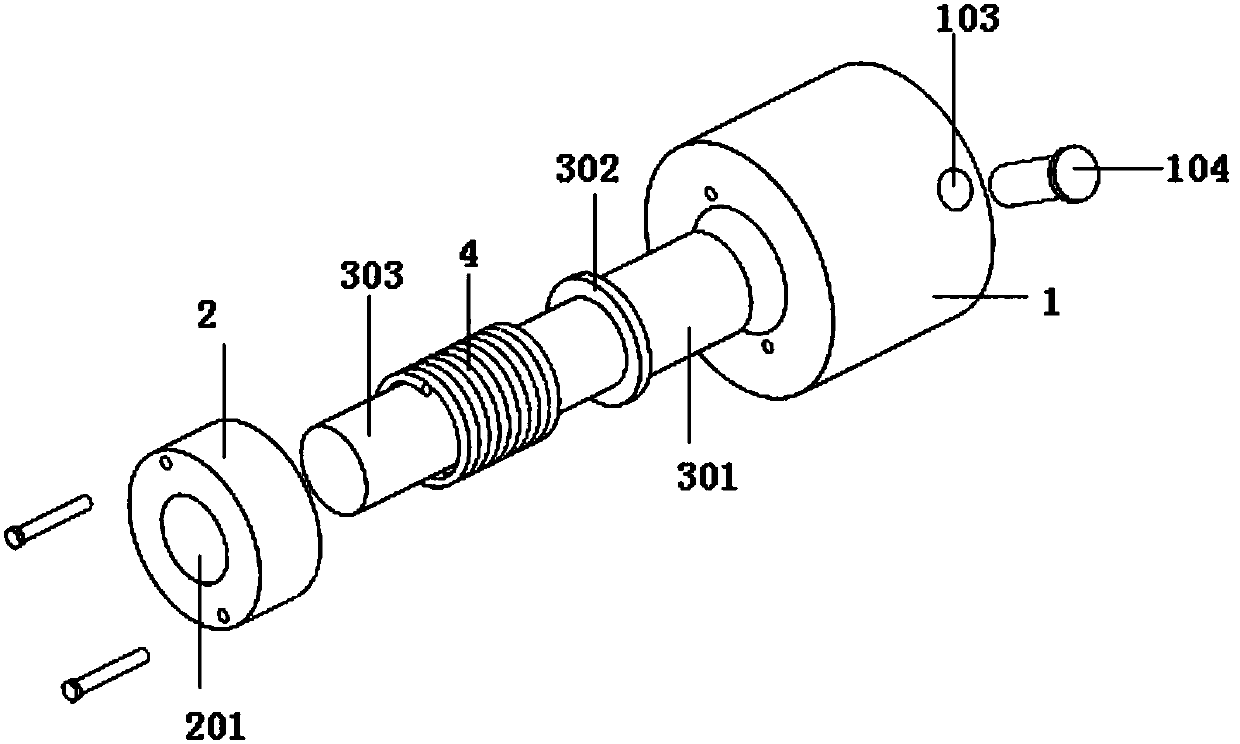

[0022] A measuring tool for measuring the depth of raceway grooves, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, including the measuring cover 1, the bottom surface of the measuring cover 1 is provided with a groove 101, and the bottom surface of the groove 101 is provided with a first through hole 102. The diameter of the groove 101 is 5-10mm larger than the diameter of the first through hole 102, and the The groove 101 and the first through hole 102 form the installation through hole, and the measuring rod 3 is installed in the installation through hole. A compression screw 104 is installed in the 103, and the compression screw 104 is tightly connected with the side wall of the measuring rod 3;

[0023] The bottom of the measuring sleeve 1 is fixed with a gland 2, the surface of the gland 2 has a second through hole 201, the inner diameter of the second through hole 201 is 5-10 mm smaller than the diameter of the groove 101, and the measuring rod 3 pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com