Method for determining content of lead in silver alloy

A silver alloy and titration technology, which is applied in the field of analytical chemistry, can solve the problems of no suitable silver alloy determination method, and achieve the effects of wide determination range, accurate determination and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

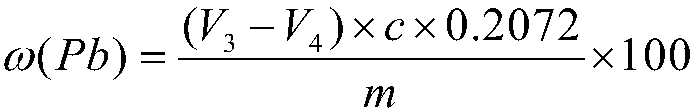

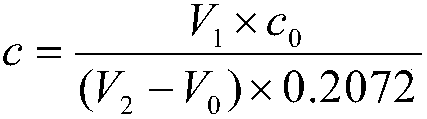

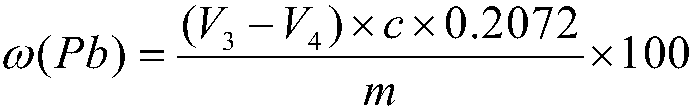

Method used

Image

Examples

Embodiment 1

[0037] Include the following steps:

[0038] Step 1. Weigh 0.3000g sample and put it into a 400mL beaker, record it as m, then add 10mL concentrated nitric acid, cover the watch glass, and heat it on an electric hob at 150°C. After the sample dissolves, take it out and cool it to room temperature;

[0039] Step 2: Add 10mL of sulfuric acid to the above beaker, heat to smoke for 2min, remove and cool to room temperature, rinse the surface and the beaker wall with deionized water, add deionized water to 80mL, heat to boil for 10min, remove, Cool to room temperature, add 5mL ethanol, and let stand for 1 hour;

[0040] Step 3, filter with slow quantitative filter paper, wash the beaker 3 times with sulfuric acid lotion with a concentration of (2+98), wash the precipitate 6 times, check the filtrate with a potassium thiocyanate solution with a concentration of 50g / L until no red appears Wash the beaker and precipitate twice with deionized water, and discard the filtrate;

[0041]...

Embodiment 2

[0073] Step 1. Weigh 0.3000g sample and put it into a 400mL beaker, record it as m, then add 15mL concentrated nitric acid, cover the watch glass, and heat it on an electric stove at 180°C. After the sample dissolves, take it out and cool it to room temperature;

[0074] Step 2: Add 12mL of sulfuric acid to the above beaker, heat it to smoke for 3min, remove it and cool it to room temperature, rinse the surface and the wall of the beaker with deionized water, add deionized water to 90mL, heat and boil for 12min, remove it, Cool to room temperature, add 8mL ethanol, and let stand for 1.5 hours;

[0075] Step 3, filter with slow quantitative filter paper, wash the beaker 4 times with sulfuric acid lotion with a concentration of (2+98), wash the precipitate 7 times, check the filtrate with a potassium thiocyanate solution with a concentration of 50g / L until no red appears Wash the beaker and precipitate twice with deionized water, and discard the filtrate;

[0076] Step 4. Put t...

Embodiment 3

[0108] A method for measuring lead content in silver alloys, the concrete steps are as follows:

[0109] Step 1. Weigh 0.3000g sample and put it into a 400mL beaker, record it as m, then add 20mL concentrated nitric acid, cover the watch glass, and heat it on an electric stove at 200°C. After the sample dissolves, take it out and cool it to room temperature;

[0110] Step 2: Add 15mL of sulfuric acid to the above beaker, heat it to smoke for 5min, remove it and cool it to room temperature, rinse the surface and the wall of the beaker with deionized water, add deionized water to 100mL, heat and boil for 15min, remove it, Cool to room temperature, add 10mL ethanol, and let stand for 2 hours;

[0111] Step 3, filter with slow quantitative filter paper, wash the beaker 5 times with sulfuric acid lotion with a concentration of (2+98), wash the precipitate 8 times, check the filtrate with a potassium thiocyanate solution with a concentration of 50g / L until no red appears Wash the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com