belt splicer

A technology of splicers and belts, applied in the direction of belts/chains/gears, belt fasteners, household appliances, etc., which can solve the problems of manual insertion and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

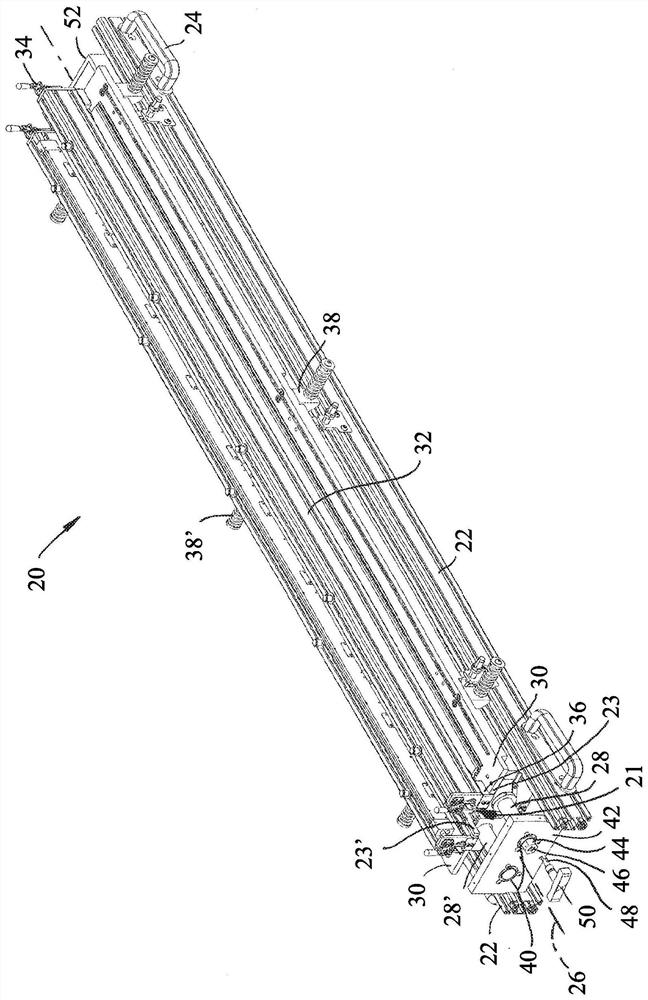

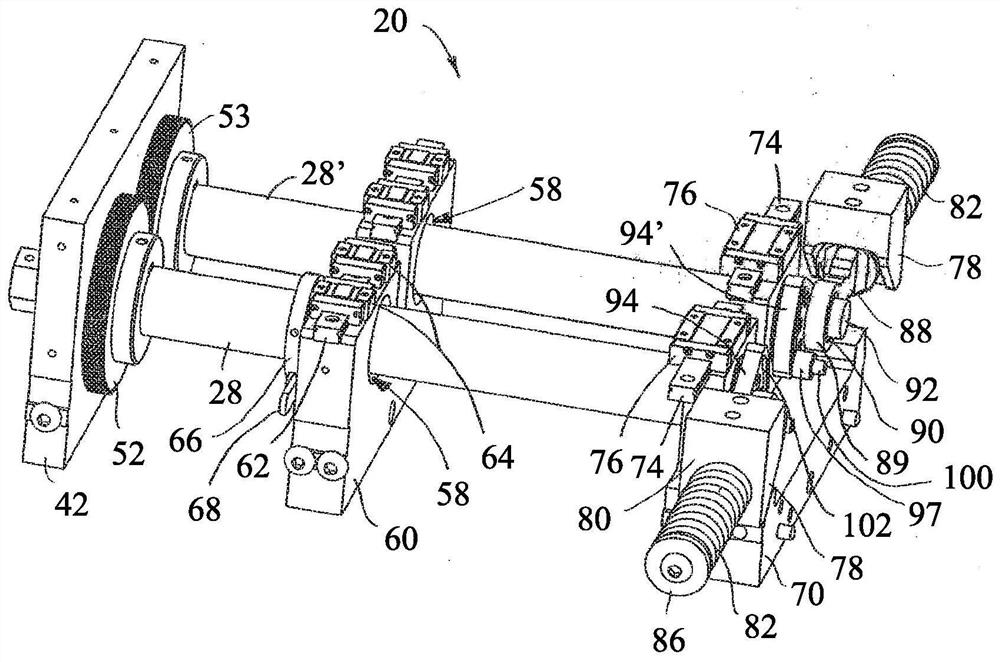

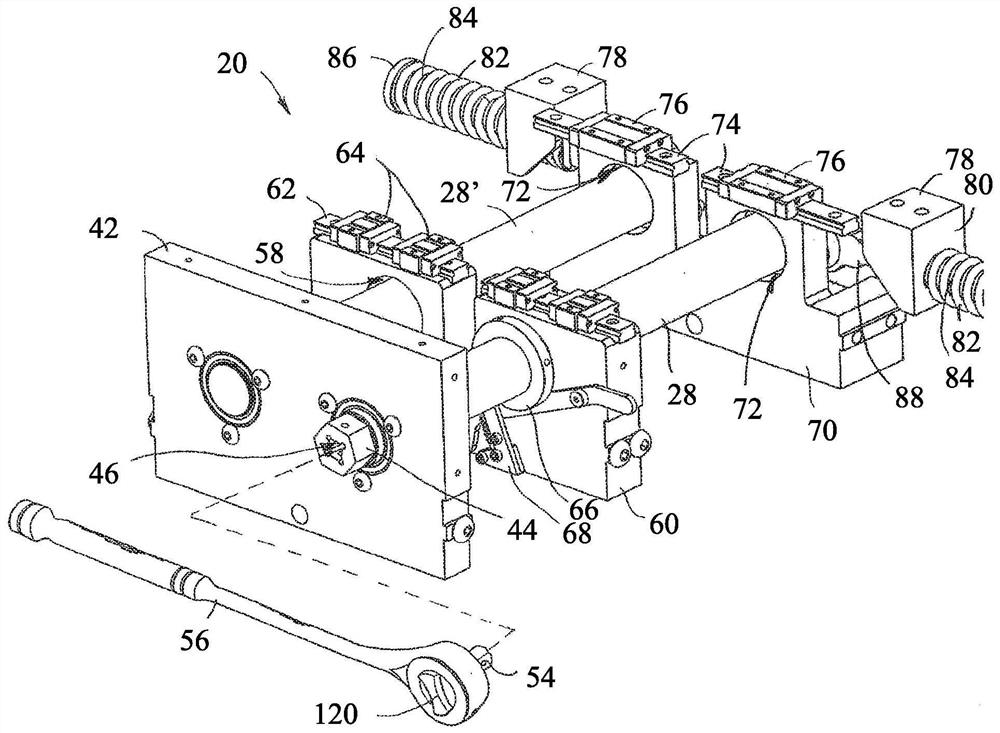

[0015] figure 1 A belt splicer embodying features of the invention is shown in . The splicer 20 includes a rod positioner and jaws 21 supported between a pair of frame rails 22 . Handles 24 attached to the frame 22 at each end contribute to the portability of the splicer. The jaw 21 is divided into a right jaw 23 and a left jaw 23', each jaw being a nearly identical mirror image of the other with respect to a vertical plane passing through the axial centerline 26 of the splicer. Each half 23, 23' of the jaws 21 includes an axis 28, 28' extending parallel to the centerline 26 in the width direction of the splicer. Rotation of the shaft opens and closes the jaws 21 . Each jaw 23, 23' also has an upper deck 30 on which the two belt end sections to be spliced together sit. The belt end sections may be opposite ends of a single belt or the ends of individual belt sections to be spliced together. Rotation of the shafts 28, 28' translates the left jaw 23 and the right j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com