Sealing portion of wellbore

A wellbore, positioned technology, applied in the directions of sealing/packing, wellbore/well components, production fluid, etc., can solve the problems of drilling rig loss, inability to provide technical solutions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

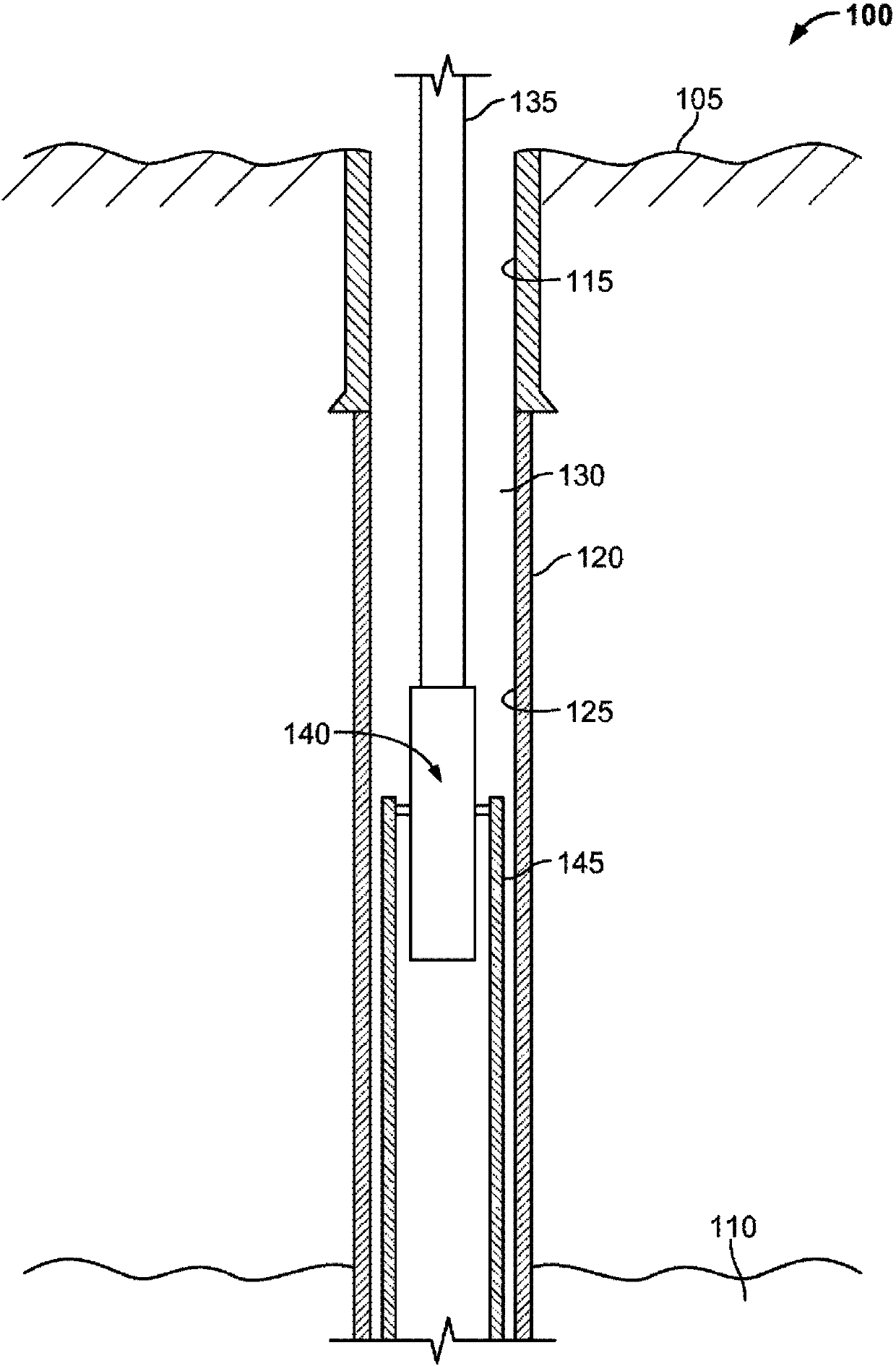

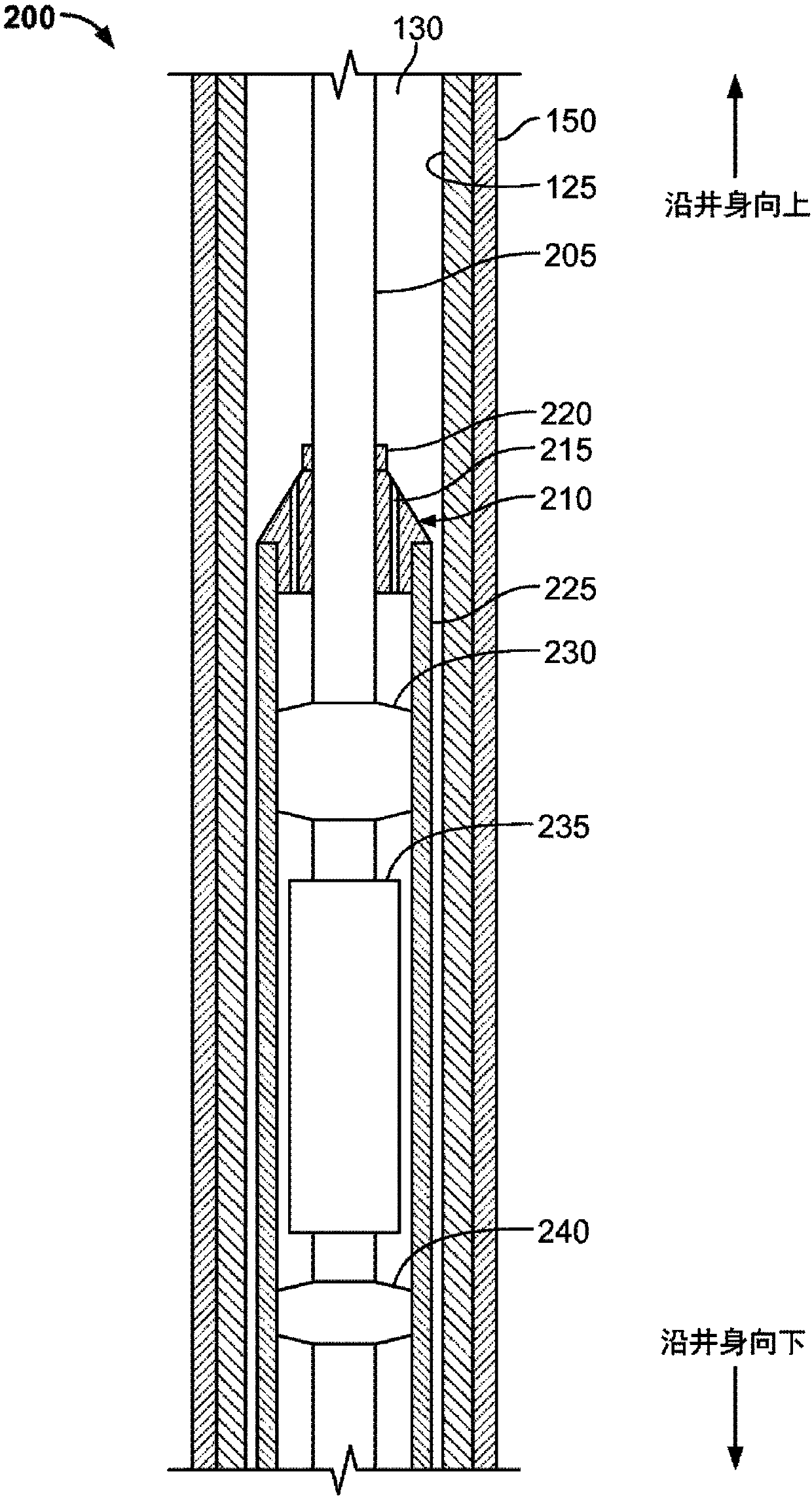

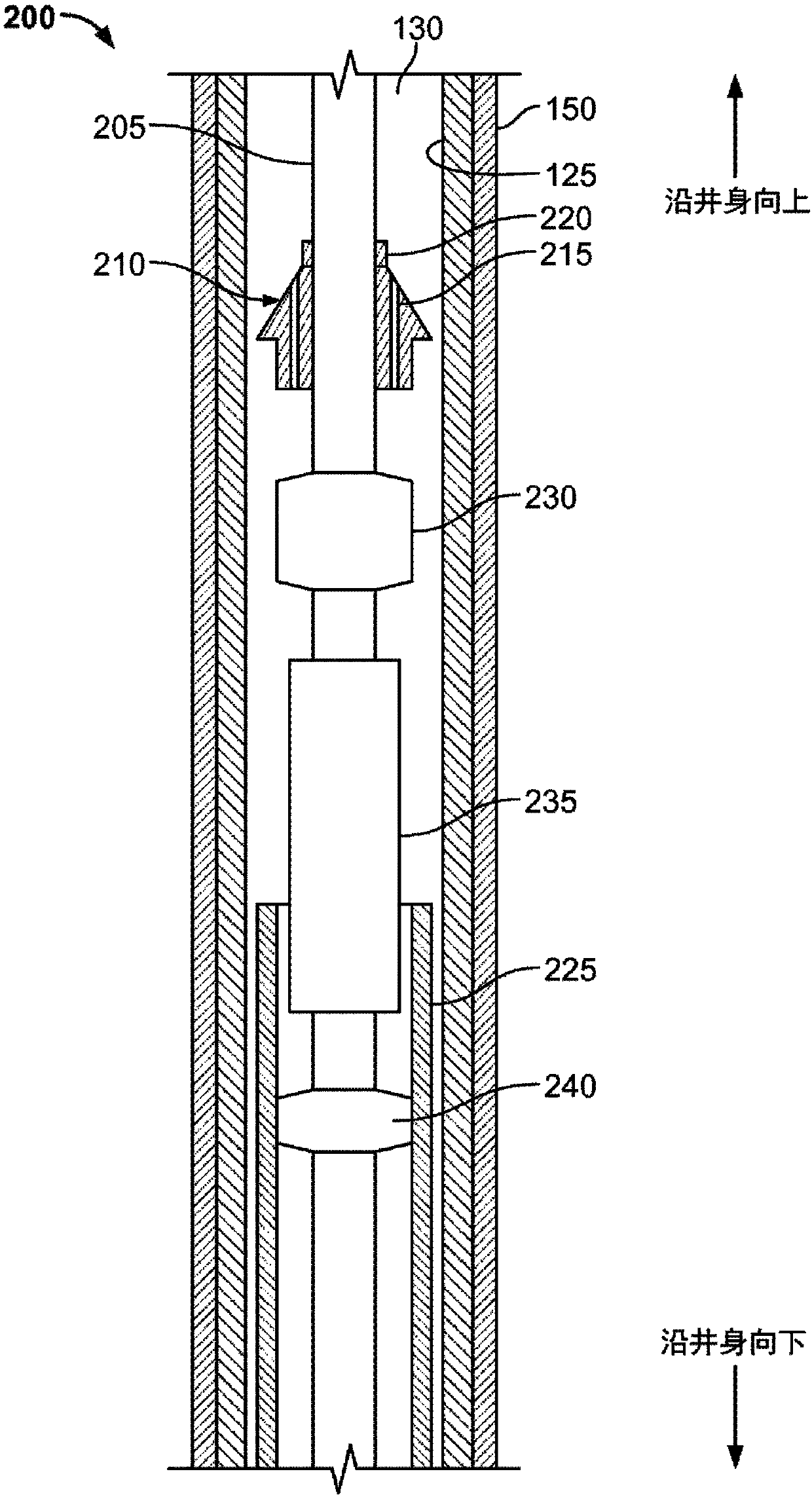

[0031] figure 1 is a schematic diagram of an exemplary wellbore system 100 including a liner top system 140 . Overall, figure 1 A portion of one embodiment of a wellbore system 100 is shown in which a liner top system 140 may be lowered into a wellbore 120 to install the liner adjacent to casing 125 (eg, production or otherwise casing) in accordance with the present invention 145. In some aspects, the liner top system 140 can also centralize the liner 145 prior to installation, and install a sealing member (e.g., a packer, liner top packer, or packing element) on the top of the liner 145. at the top.

[0032] In some aspects, the liner 145 is an alternative to a conventional liner suspension system (e.g., the liner suspension system includes a liner hanger with a slide, a liner top packer, and a tieback or polish hole receiver ) bare casing joints. For example, in cases where the wellbore 120 is deviated or is a horizontal wellbore section, the weight of the liner can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com