Adjustable electronic component processing platform

A technology for electronic components and processing platforms, which is applied to workbenches, manufacturing tools, and wiring harnesses, etc. It can solve the problems of component confusion, inconvenient adjustment, and easy scattering of components, and achieve easy operation, good dustproof ability, Good support and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

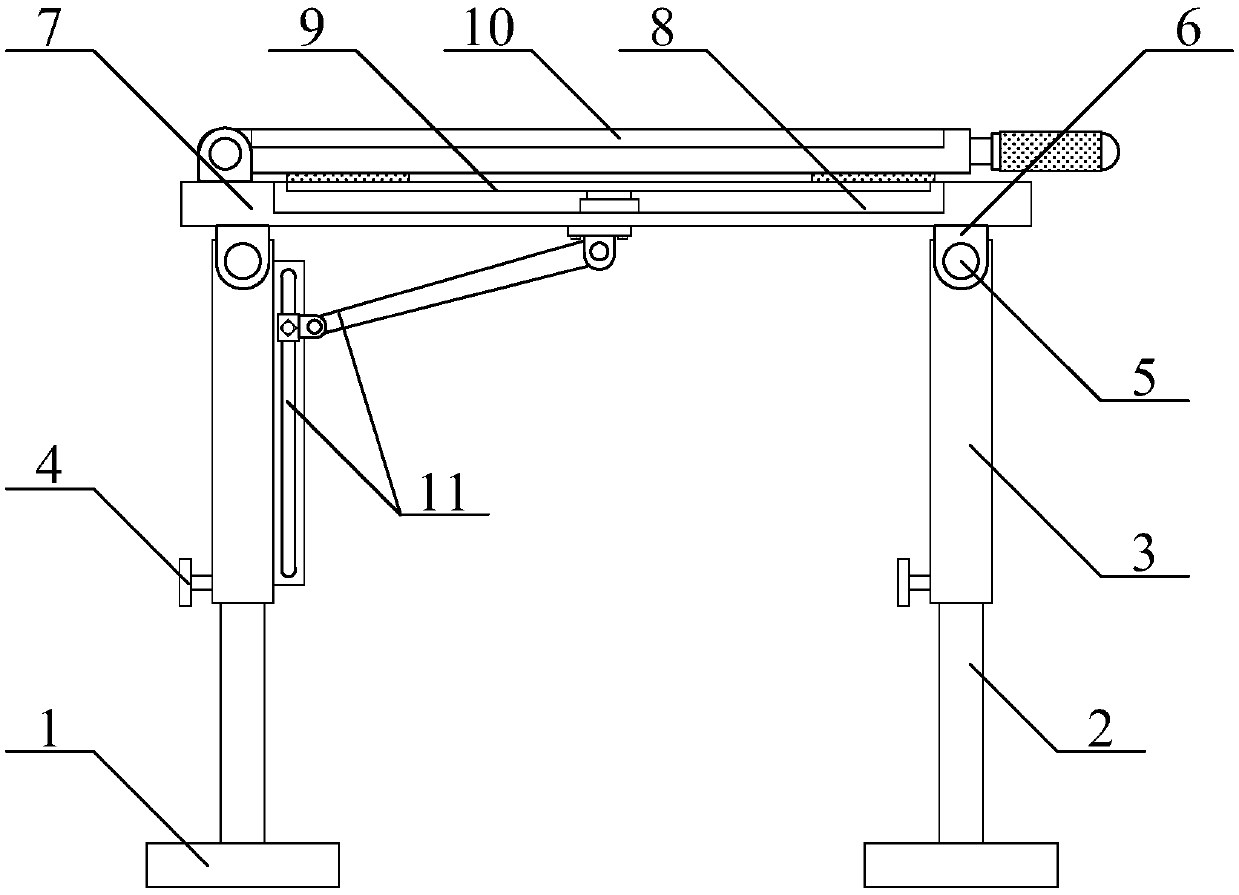

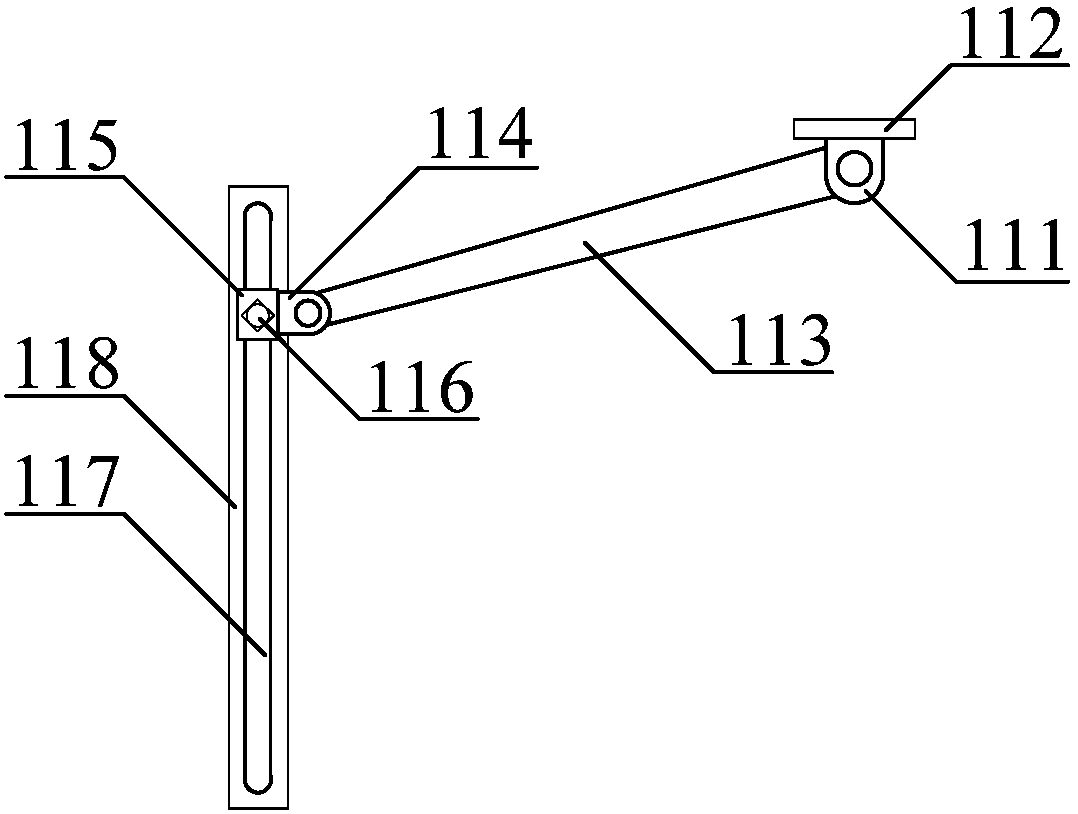

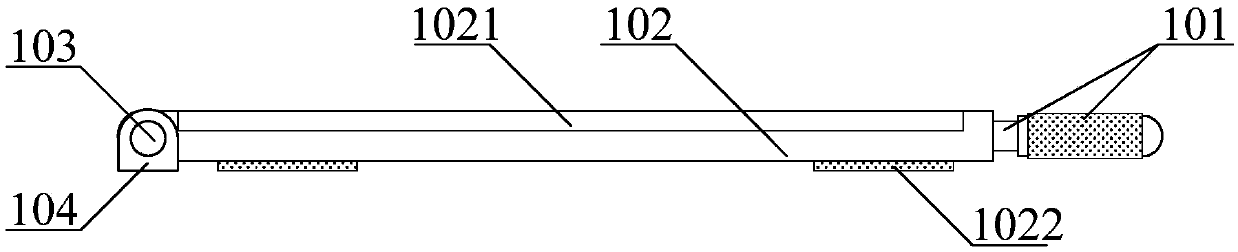

[0035] as attached figure 1 To attach Figure 5 shown

[0036] The invention provides an adjustable processing platform for electronic components, which includes a foot base 1, a telescopic rod 2, a rotating sleeve 3, an adjusting bolt 4, a rotating shaft 5, a fixing seat 6, a working platform body 7, a groove 8, a rotating The disc structure 9, the shield structure 10 and the sliding support plate structure 11, the foot 1 is screwed to the bottom of the telescopic rod 2; the telescopic rod 2 is longitudinally inserted into the inner lower part of the rotating sleeve 3; The adjusting bolt 4 is threadedly connected to the junction of the rotating sleeve 3 and the telescopic rod 2; the top of the rotating sleeve 3 is connected to the inside of the fixed base 6 through the rotating shaft 5; the fixed base 6 is bolted to the The four corners of the bottom of the working platform body 7; the groove 8 is set on the inner upper part of the working platform body 7; the rotating disk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com