Concrete manufacturing equipment and method of use thereof

A technology for manufacturing equipment and concrete, which is applied in the direction of clay preparation equipment, mixing operation control, chemical instruments and methods, etc., can solve the problems of waste of water resources, backward existing methods, high energy consumption, etc., achieve efficient recycling, realize automation, The effect of solving waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment mainly introduces the main structure of a concrete manufacturing equipment of the present invention.

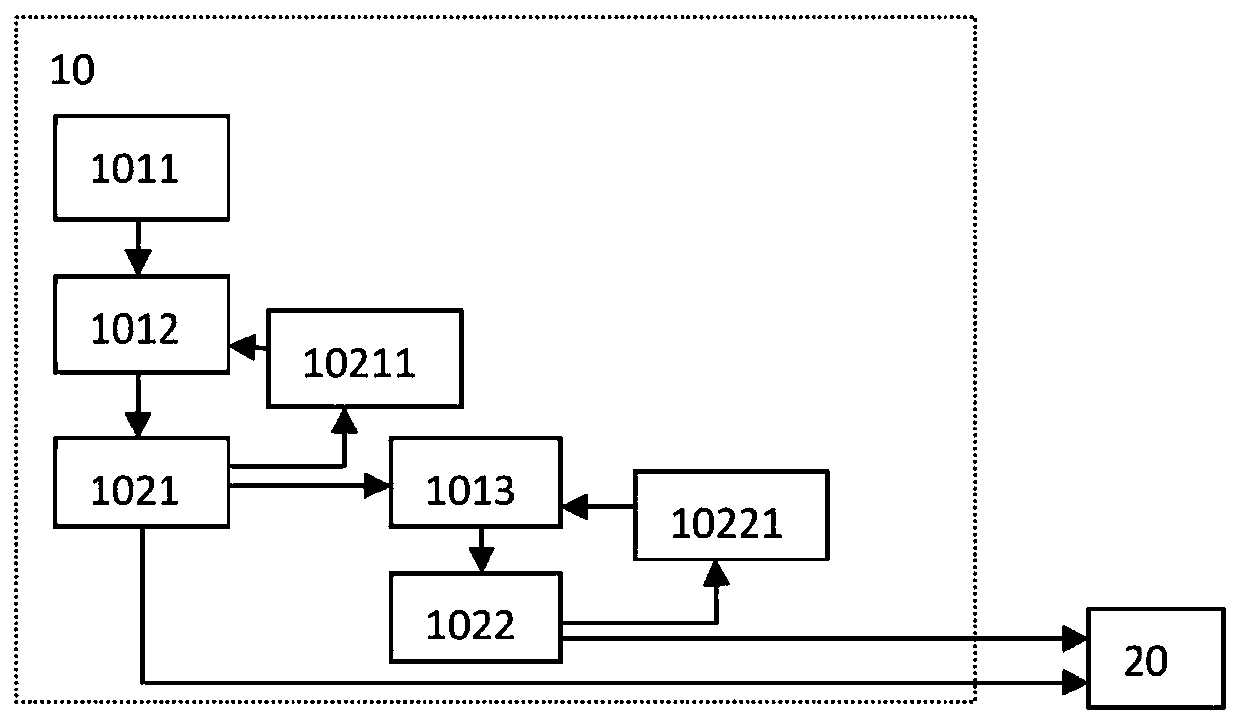

[0055] as attached figure 1 As shown, a concrete manufacturing equipment 1 includes a rotating device 10 and a conveying device 20 .

[0056] Further, the aforementioned concrete manufacturing equipment 1 also includes a mixing equipment 30 .

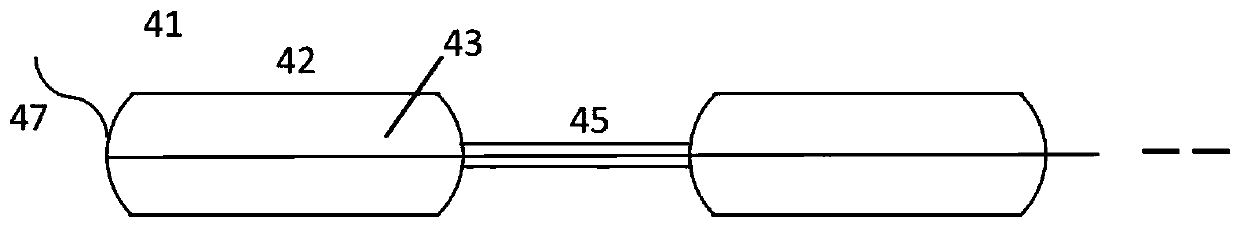

[0057] Further, the aforementioned concrete manufacturing equipment 1 also includes a pipeline cleaning device 40 .

[0058] Further, the aforementioned concrete manufacturing equipment 1 also includes concrete curing equipment 50 .

[0059] The rotating device 10 includes a crushing device 101 and a screening device 102 .

[0060] Further, the crushing device 101 is a multi-stage crushing device, including a first-stage crushing device 1011 , a second-stage crushing device 1012 , and a third-stage crushing device 1013 .

[0061] Further, the screening device 102 is a multi-stage screening device, including a...

Embodiment 2

[0069] This embodiment is carried out on the basis of the foregoing embodiment 1, and mainly introduces a method of using the concrete manufacturing equipment of the present invention.

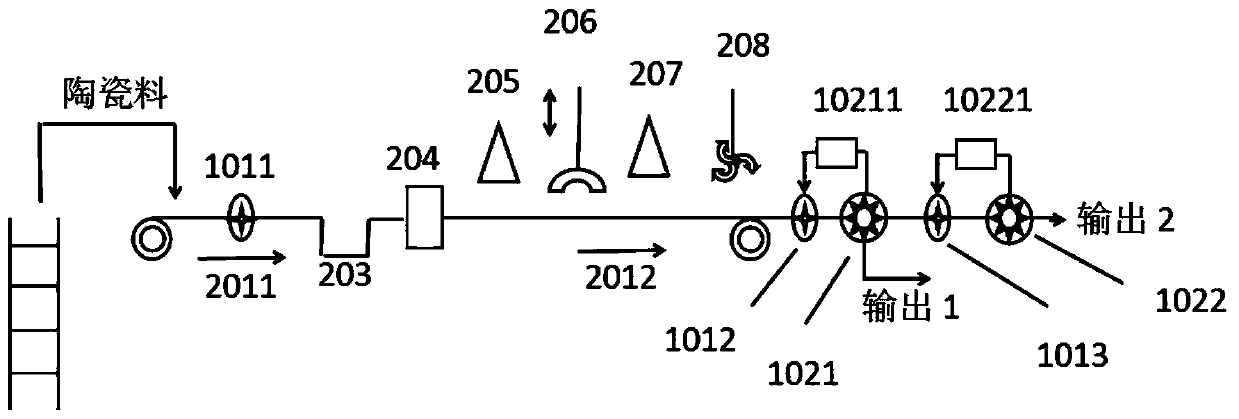

[0070] as attached figure 2 As shown, the recycling process using the rotating device 10 and the conveying device 20 of the concrete manufacturing equipment is as follows:

[0071] Step 1. The recycled ceramic material is transported and transported to the first-stage crushing device 1011 through the first conveyor belt 2011. After crushing, the particle size of the ceramic (recycled) material is less than 20 mm; the particle size of the crushed ceramic material is 10-20 mm. , preferably 15 mm.

[0072] Step 2: The ceramic material pulverized in step 1 passes through the cleaning tank 203 to be cleaned and dried. Reagents are used for cleaning to remove dust and oil, and the cleaned sewage is stored for later use. Drying adopts drying equipment 204: hair dryer or drying. Cleaning methods i...

Embodiment 3

[0083] This embodiment is carried out on the basis of aforementioned embodiment 1 or 2, mainly introduces the using method of a kind of concrete manufacturing equipment of the present invention, adopts the following proportioning for making concrete with recycled materials by using the aforementioned equipment:

[0084] The material mixing equipment 30 uses the environmentally friendly sand and environmentally friendly micro-materials obtained in the recycling process for the preparation of concrete.

[0085] Environmentally friendly sand and environmentally friendly micro-materials replace part of the natural sand and cement gelling agent respectively, and the replacement ratio is as follows:

[0086] Environmentally friendly sand material: total weight of sand material = 10%-40%: 1; preferably 15%, 20%, 30%, 35%;

[0087] Environmentally friendly micro-materials: total weight of cement gelling agent = 1%-15%: 1; preferably 5%, 8%, 10%, 12%;

[0088] The proportion of ready-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com