3D printing shoe device and using method thereof

A 3D printing and 3D printer technology, applied in other home appliances, footwear, applications, etc., can solve the problems of difficult to achieve different materials, poor sealing, etc., to achieve the effect of increasing diversity, simple structure, and excellent sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

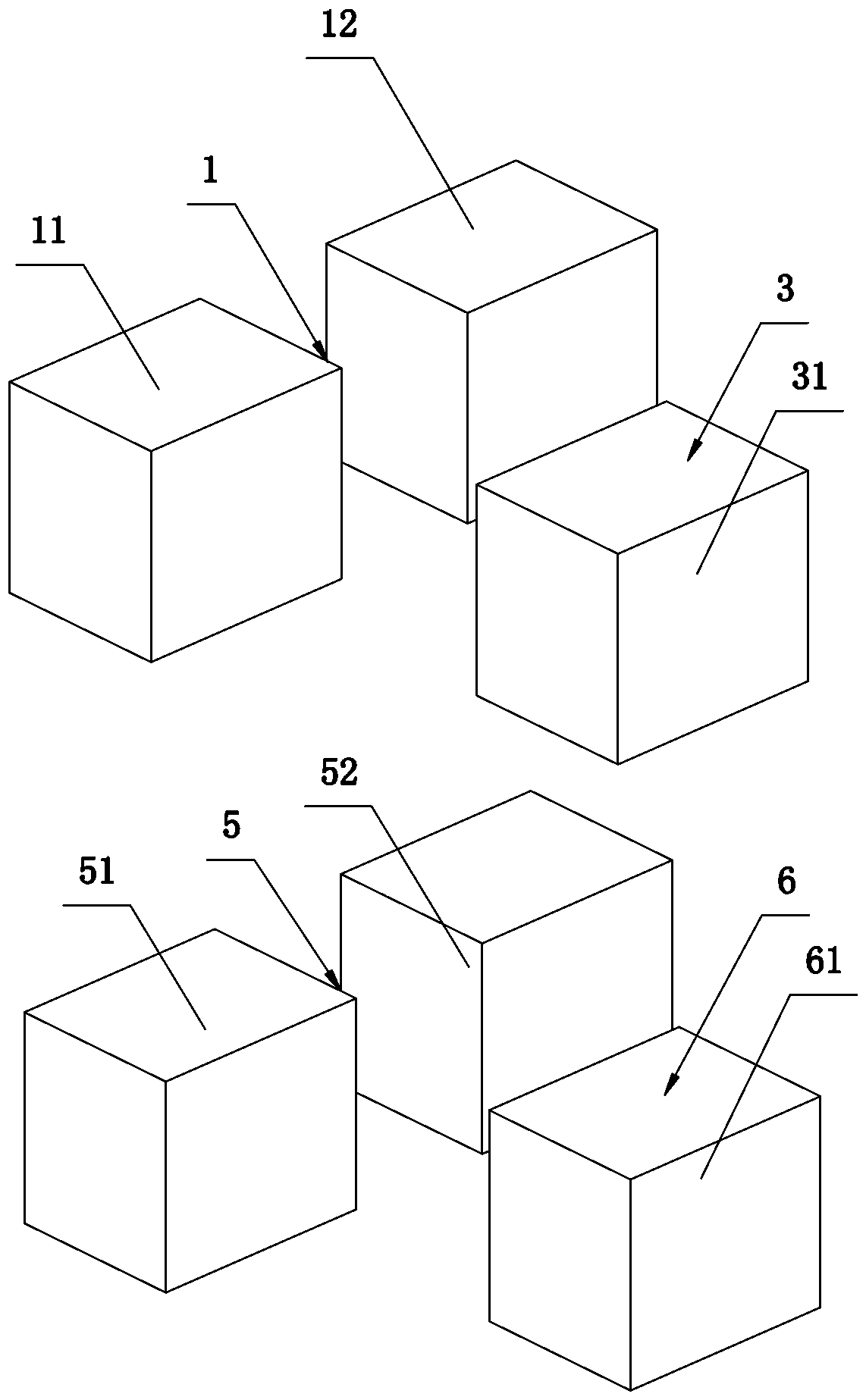

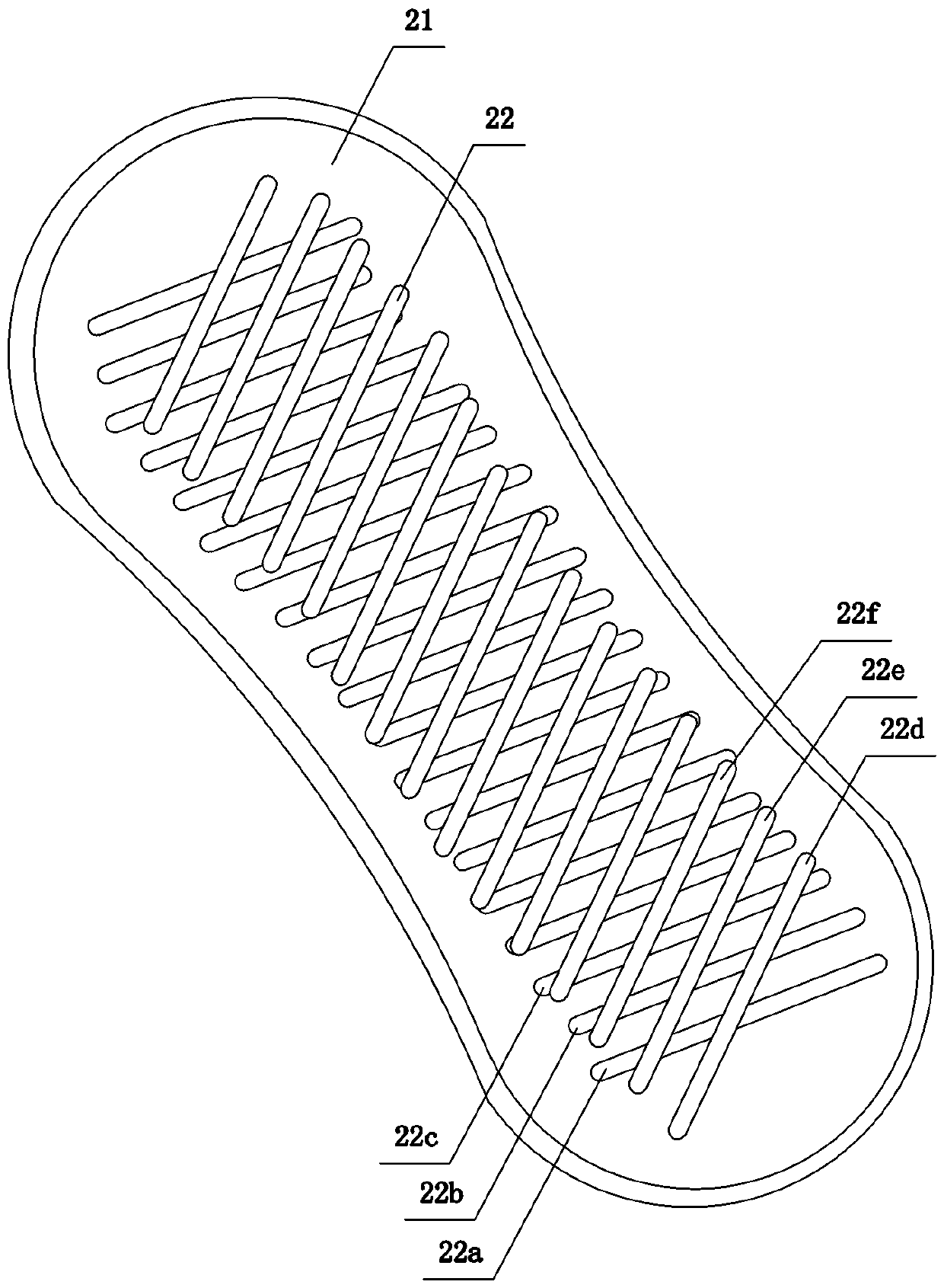

[0032] refer to figure 1 , figure 2 , image 3 and Figure 4 . A device for 3D printing shoes, comprising:

[0033] The sole printing device 1 is used for printing the sole 2;

[0034] The upper printing device 3 is used to print the upper 4;

[0035] Hot-pressing dotting device 5, used for dotting on the sole 2, and hot-pressing the vamp 4 on the sole 2 according to the dotted position;

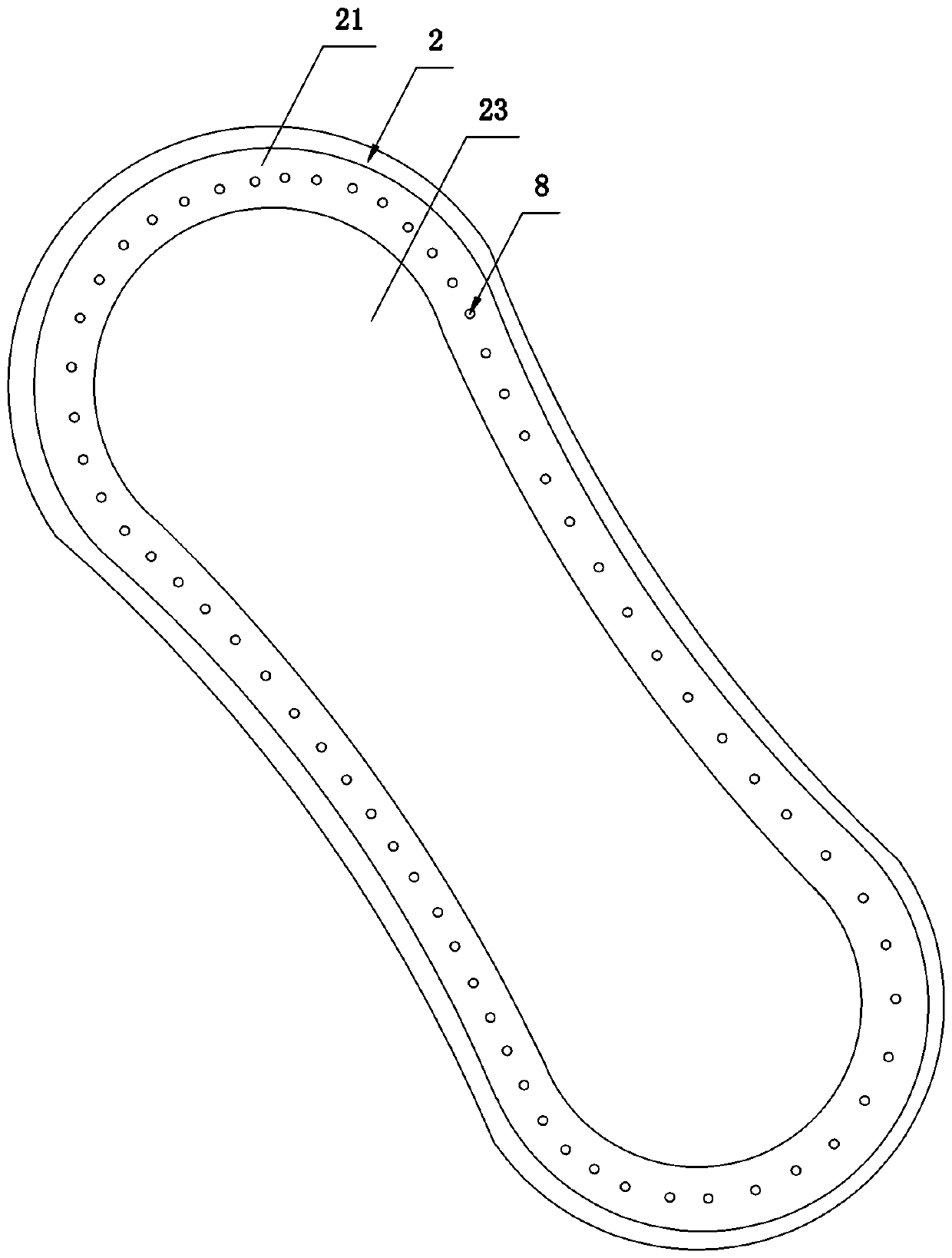

[0036] 3D printing gluing device 6, used to print the sealing strip 7 connected to the joint between the sole 2 and the upper 4 to achieve sealing;

[0037] The printing materials in the sole printing device 1 and the shoe upper printing device 3 may be the same or different.

[0038] The present invention is simple in structure and strong in practicability. The shoe sole printing device 1 and the shoe upper printing device 3 are respectively arranged to print ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com